How the US Tariff on Teflon May Affect the Industries That Use It

A new tariff on polytetrafluoroethylene (more commonly known as PTFE, or Teflon) from China and India is shaking up the Teflon market and the industries who use it.

From cookware and surgery to aerospace and automobiles, PTFE is used in many ways on our daily lives.

This tariff could even affect Eclipse Engineering, as we use PTFE to solve problems on a daily basis.

What is PTFE?

The most common trademarked product made from PTFE is Teflon.

Teflon is a synthetic material that is recognized for its durability and ability to function in a wide range of temperatures ( -450F to 575F ).

Teflon is commonly called upon for its low-friction properties and its inertness , which makes it compatible for use with most chemical compounds.

Because of its diversity of attractive properties, PTFE is in high demand across the world. The global market for PTFE, in fact, is expected to reach $2.9 billion by the year 2022.

Common Applications for PTFE

Non-stick Coating

One of the most common uses for PTFE can be found in the kitchen. Teflon is the main component of non-stick coating for pots and pans.

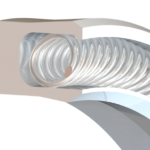

Seals

PTFE’s low-friction properties in combination with its chemical inertness also make it a go-to for seals used in equipment — especially in rotary power applications.

Think gear pumps, compressors, and generators. Eclipse often turns to PTFE seals for these applications.

Medical Equipment

Another important use of PTFE is in surgical equipment.

Its non-stick properties are perfect for surgical tools and packaging. And when combined with a non-acid formula, it prevents bacteria from growing on surfaces, keeping them sterile.

Other Uses

There are still more applications of PTFE:

What Does the PTFE Tariff Do?

The new tariff is essentially a tax or duty that Chinese and Indian producers of PTFE pay when exporting the material to America.

The current administration says the tariff is in place because it believes that the foreign product is currently underpriced.

With almost $24.6 million in PTFE exports to the US from China alone , plus another $14.3 million from India , the tariff is expected to have an impact on the American economy.

What Effects Will the Tariff Have?

The answer to this question isn’t clear.

The US Commerce Dept. is currently making preliminary determinations about the tariff based on its effects.

It’s scheduled to make final decisions about the tariff this fall.

In terms of immediate effects, the prices on PTFE have risen and are now sitting at a 4-year high. We won’t know how much the tariff might affect the price of products that use PTFE until next year.

Whether or not consumers will feel the impact of this price change depends on if companies that make products with PTFE can find cost-savings elsewhere. It will also depend on wither manufactures can find alternatives at cheaper prices from places other than China or India.

PTFE is too valuable to be rendered obsolete because of price fluctuations. Immeasurable products that enhance our daily lives rely on PTFE.

Regardless of the impact of the tariff, Eclipse Engineering will continue to deliver the most accessible and affordable PTFE options to our clients.