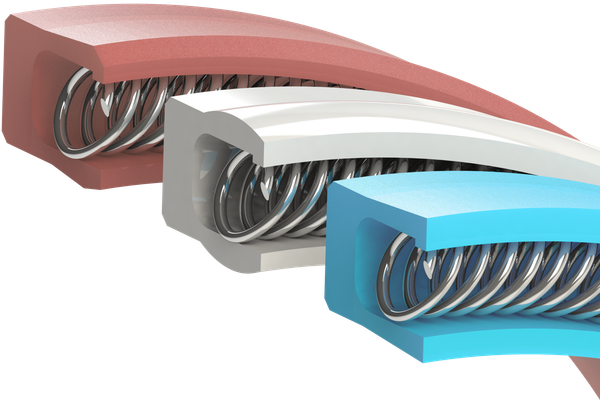

Full service seal & bearing engineering, manufacturing and distribution.

For seals and bearings to work correctly, they need to fit correctly.

With Eclipse Engineering, you can have your bearings, seals, and shapes designed and manufactured in one place, ensuring the perfect fit. Let us show you what the highest level of engineering support looks like.

AEROSPACE

Eclipse produces high-precision seals for the aerospace industry, including high performance seals for extreme aerospace environments. Applications include aircraft braking systems, gearboxes, flap actuators, satellites, cryogenic refueling systems, turbo pumps, launch pad dampeners, and armored transporters.

PHARMACEUTICAL

We provide high reliability seals for the pharmaceutical industry and perfect-fit seals for pharmaceutical applications––for process equipment including HPLCs, batch reactors, centrifuges, and autoclaves. Our clients include pharmaceutical manufacturers and pharmaceutical process equipment OEMs.

ENERGY, OIL & GAS

We produce perfect-fit seals for the energy industry (including solar, wind, hydro, coal, and nuclear plants) plus seals for the oil and gas industry covering exploration, refining, production, and completion activities. Our seals reside in products such as control valves, reactors, couplings, regenerators, drill heads, blowout preventers, and dam trunnions.

MEDICAL EQUIPMENT

We provide customized medical seals and advanced seals for the medical equipment industry––including dental and surgical equipment, and prosthetics. Eclipse works with product engineering and purchasing staff to understand specific medical equipment needs in order to find short lead-time solutions to support your manufacturing operation.

FOOD & BEVERAGE

We provide seals for the food and beverage industry, food-grade rubber seals, and food-safe o-rings. Cost-efficient solutions are offered for a wide range of processing, packaging, and handling equipment––including fold boxes, filling containers, and conveyors. Eclipse works with product engineering, maintenance, and purchasing staff to understand specific production equipment needs in order to find short lead-time solutions to keep your production up and running.

SEMICONDUCTOR

Eclipse produces high-reliability seals for the semiconductor industry, seals for semiconductor applications, and for the broader electronics sector. We work with purchasing and engineering staff to understand specific equipment needs in order to find short lead-time solutions to support your business.

AUTOMOTIVE

Eclipse produces cost-effective seals for the automotive industry and seals for automotive applications. We work with engineers and purchasing staff of automotive OEMs and component suppliers to understand specific manufacturing needs––enabling us to find economic short lead-time solutions to support your production.

INDUSTRIAL

Eclipse produces cost-effective, high quality, seals for industrial applications and a wide range of mechanical seals––for cylinders, actuators, valves, farm machinery, drilling equipment, mining machinery, and many other applications. We work with equipment manufacturers and rebuilders to understand specific needs––enabling us to find economic short lead-time solutions to support your operation.

WE DESIGN, MANUFACTURE, AND DISTRIBUTE

You can find the products we design, manufacture, and distribute all over—and even off—the planet

Eclipse Engineering was the brainchild of a passionate, business-minded engineer. His goal was to provide answers to seal and bearing questions to a niche market. Since operations began in 1999, Eclipse has evolved into a comprehensive partner for many OEM, MRO and industrial customers around the world. These companies have come to count on our engineered solutions, problem solving skills, in-house manufacturing capabilities and the responsiveness associated with distribution.

Our staff has more than 200 years of combined seal and bearing experience. This experience allows us to determine if a standard off the shelf product can be used or if an engineered solution will be required for an application.

At Eclipse, we've designed seals:

- In reciprocating, oscillating, rotary and static applications

- That work in applications in excess of 500K PV

- To maintain extreme vacuum

- To withstand 100K PSI

- To contain radioactive water, fire resistant hydraulic fluid, H2S, solvents, and more

As a top tier supplier, we strive to continually improve our processes, while keeping with the essential principle of providing, foremost, engineering and technical assistance that results in an optimized solution for your sealing application.

From our sales professionals to our engineers, we take pride in the fact that we listen to our customers' needs and provide them with quality products—at a competitive price, in a timely manner.

-

City skyline

Photo By: John DoeButton

A HIGHER STANDARD IN THE MECHANICAL SEAL INDUSTRY

At its inception, Eclipse built its business model around listening and reacting to customer’s mechanical seal needs. Industrial markets demanded cost effective, short-lead time products backed up by engineering support. Eclipse responded by bolstering its engineering staff and increasing seal production capabilities.

In order to supply to many different industries, Eclipse designed engineered solutions that met stringent standards. By listening to our customers, Eclipse has gained wide ranging industry experience and is ready to apply this knowledge to your specific application. In 2015, we earned our AS9100 and ISO9001 Certification to better serve our customers and provide the best customer service in our industry.

-

City skyline

Photo By: John DoeButton

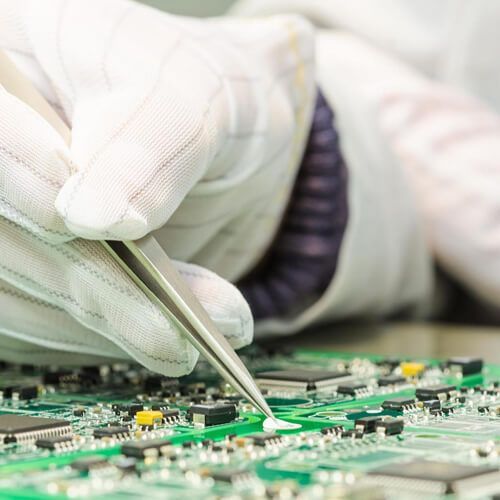

IN HOUSE ENGINEERING, MANUFACTURING, AND DISTRIBUTING

Eclipse Engineering is a full service manufacturing and engineering company for seals and bearings. While we specialize in the production of machinable plastics, we provide sealing solutions to our customers in many different areas, including fluid pump assemblies, pneumatic and hydraulic cylinders, fluid control systems, and even products in the aerospace, automotive, pharmaceutical, and semiconductor industries.

We are one of the only seal manufacturing company that also specializes in engineering, so you can rely on us to produce exactly the seal, bearing or spring, that you require. We will engineer, manufacture and distribute your seal, all under the same roof, that’s why we are so confident in our work and know we can design the right product for your specific needs.

-

City skyline

Photo By: John DoeButton

MEETING ANY PRODUCT OR MATERIAL NEED

Here at Eclipse, we take the time to design and engineer a product specific for you, in the right type of material. We specialize in a multitude of industries and carry a wide variety of materials, including plastic, rubber, nylon, thermoplastic elastomer, and more. Our assertive team of engineers is ready to design the correct product to solve your mechanical seal concerns.

We can manufacture seals, bearings, springs, o-rings, back-up rings, wear rings, you name it. At Eclipse, you can be confident that our materials and products are in line with industry standards. Our lists of materials and products are consistently updated, so your project requests will be met with the most advanced approach.

-

City skyline

Photo By: John DoeButton

SUPPLYING PRODUCTS FOR EVERY PROJECT

At Eclipse, we’re pleased to offer products and materials from a variety of suppliers. We’ve partnered with companies across the United States to provide you with the best solutions for your projects.

Whether it’s one of our seals, or a seal from one of our suppliers, we promise to bring you the best possible solution for any project. We supply seals from companies like Parker, Greene Tweed, Precix, and more.

WHAT OUR CUSTOMERS HAVE TO SAY

When it comes to engineering and manufacturing seals, customer satisfaction is everything. From initial communications to the quality of the products we deliver, we always aim to be the best. Want proof? Read what some of our customers have to say about working with us!

I highly recommend Eclipse Engineering for all rubber product solutions. We have used Eclipse for reverse engineering our door seals and many other applications which require rubber parts. Eclipse has been very helpful with smoke and flame applications as required on many of our parts. I have always recommended Eclipse to any company or person needing to find rubber solutions to equipment needs.

Shawn Jakan

Everyone at Eclipse has been above board and great to work with for over 25 years plus. From design to customer service they have always responded to our needs.

Dave

We’ve been a customer of Eclipse Engineering for many years and have found them to be a very reliable source for products. They are very supportive of our stocking program on some special wear bands they have made for us. Barry has been especially helpful over the years in finding sources for other items i.e. loaded lip seals, EC121 tubing, gaskets, etc. I would recommend them as a viable source for many applications.

Jim Harsh

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!