PEEK | EP

Eclipse EP materials are based on polyether based thermoplastic resins. They are characterized by high stiffness as well as high temperature range. Unfilled grades, in some cases, can be used for seals, but generally they are used for back-up rings or ball valve seats. Several filled grades are available which can be chosen to decrease friction for dynamic applications or to increase compressive strength for load bearing applications. Eclipse EP materials have high resistance to steam and radiation making their use prevalent in the energy sector. They also maintain their physical properties when exposed to harsh chemicals such as hydrogen sulfide which makes them a material of choice in downhole applications.

Available Materials

Carbon Filled PEEK, the addition of carbon fibers enhances the comressive strength and stiffness of PEEK, and dramatically lowers its expansion rate. It offers designers optimum wear resistance and load carrying capability in a PEEK based product. This grade provides more thermal conductivity than unreinforced PEEK, increasing heat dissipation from bearing surfaces improving bearing life and capability.

Virgin PEEK, general purpose grade offers the highest elongation and toughness of all PEEK grades. PEEK can be FDA compliant.

Eclipse EP040 combines PEEK resin with carbon, graphite and PTFE. This filler system pushes the pressure velocity rating of virgin PEEK by increasing compressive load and wear resistance while also reducing friction. This combination makes EP040 an ideal choice for aggressive service bearings.

Notice:

Technical Information, test data and advice provided by

Eclipse Engineering are based on information and tests we believe to be reliable and are intended for persons with knowledge and technical skill sufficient to analyze test types and apply adequate safety factors for the given application. Because actual application conditions vary widely, these values are intended for comparitive purposes only and the suitability of this material is ultimately left to the end user.

EP030

The addition of carbon enhances the compressive strength and stiffness of PEEK, and dramatically lowers its expansion rate. It offers designers optimum wear resistance and load carrying capability. Eclipse EP030 provides more thermal conductivity than unreinforced PEEK, increasing heat dissipation from bearing surfaces improving bearing life and capability.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Density | ISO 1183 | 1.41 | g/cc |

| Tensile Strength at Break | ISO 527 | 130 | Mpa |

| Elongation at Break | ISO 527 | 5 | % |

| Melting Temperature | - | 340 | °C |

EP033

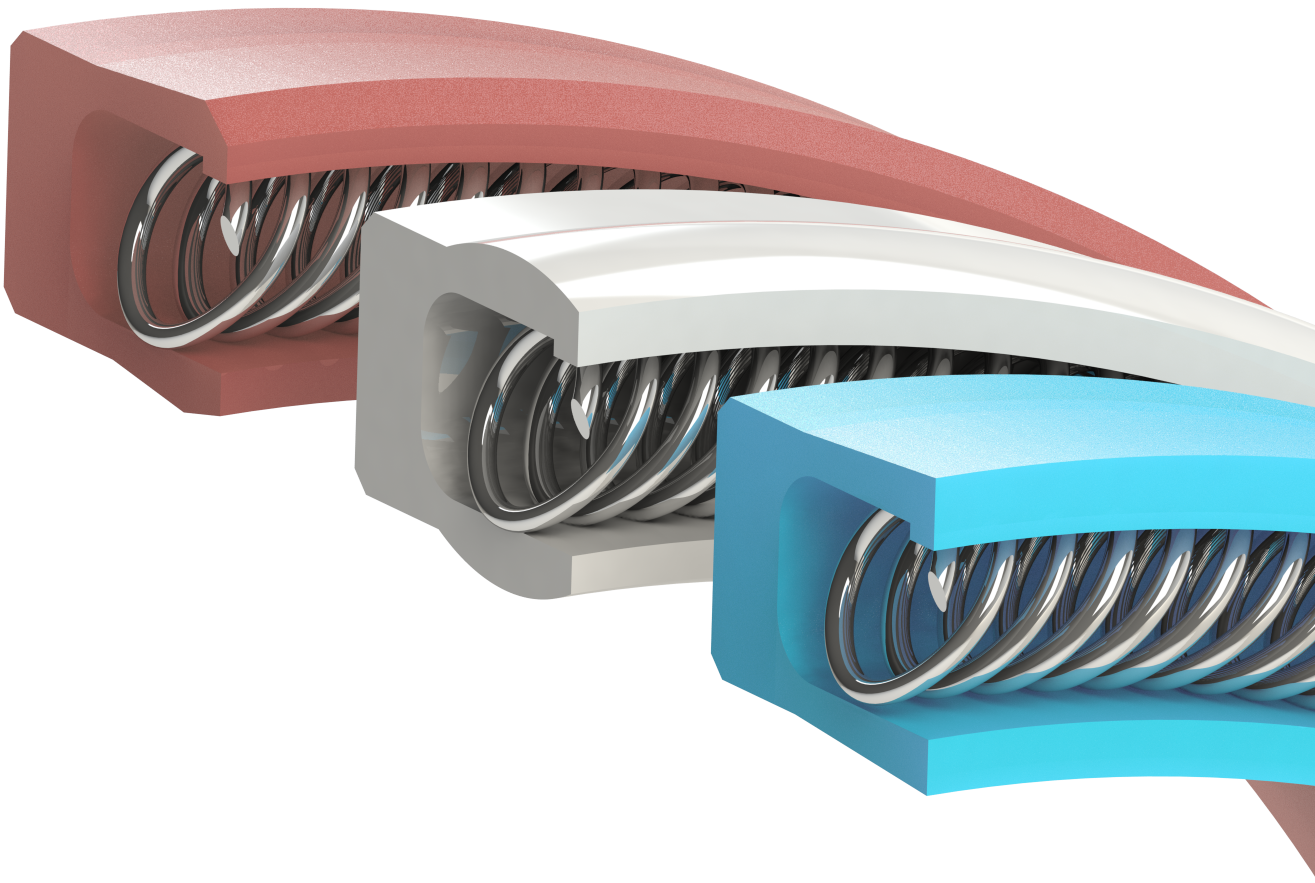

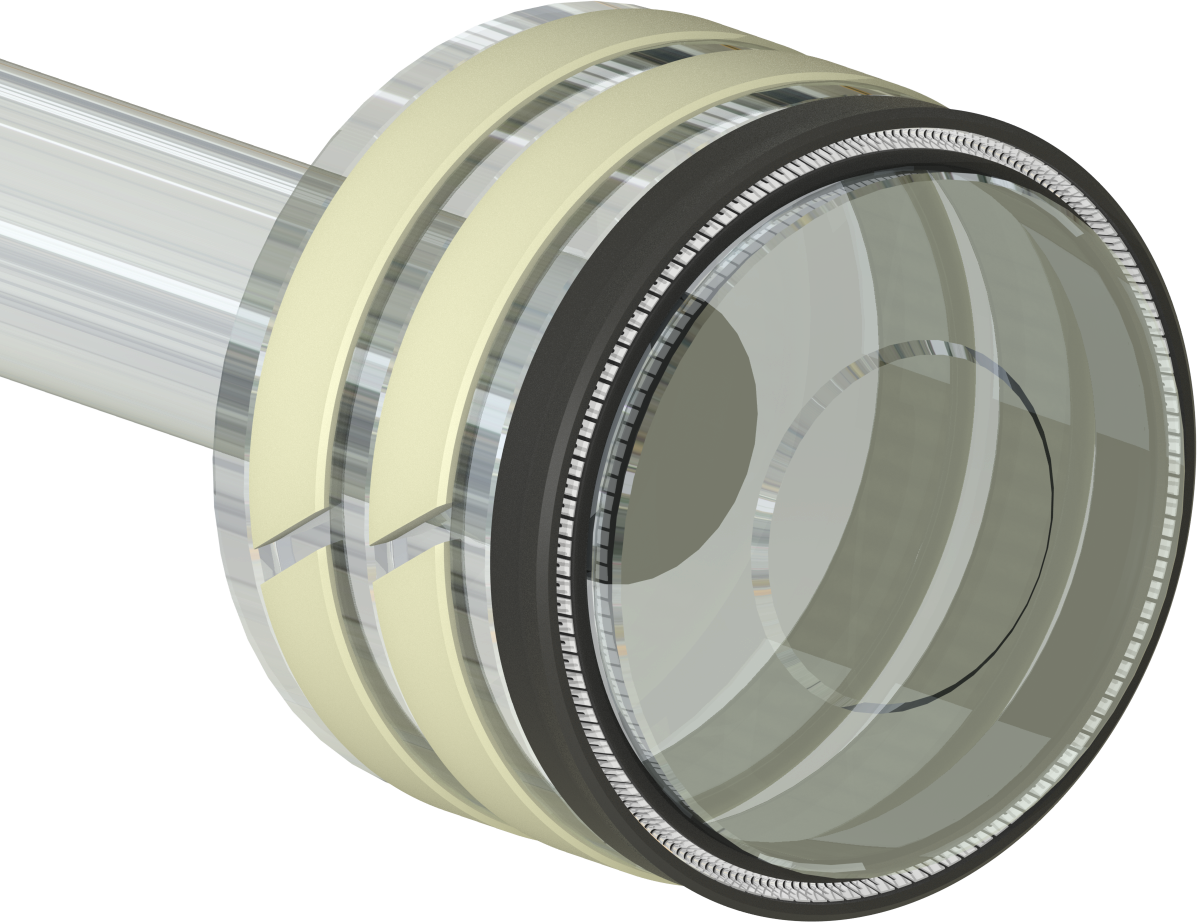

EP033 is the Eclipse unfilled grade of premium PEEK. Manufactured with melt processing techniques, EP033 is the toughest and most flexible of the EP grades. This property makes it extremely useful for back up rings which can be manufactured with a split to allow installation into solid glands. EP033 is flexible enough that, with proper design, can be machined into spring energized seals for use in corrosive environments such as downhole applications as well as saturated steam environments seen in medical and food processing equipment. EP033 is FDA compliant per 21 CFR 177.2415 for repeated food contact.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | D792 | 1.31 | - |

| Tensile Strength at Break | D638 | 16,000 | psi |

| Elongation at Break | D638 | 25 | % |

| Melting Temperature | D3418 | 644/340 | °F/°C |

EP040

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 1.44 | g/cc |

| Water Absorption | ASTM D570 (2) | 0.05 | % |

| Water Absorption at Saturation | ASTM D570 (2) | 0.3 | % |

| Hardness | ASTM D785 | 85 | Rockwell M |

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!