Wipers/Scraper Seals/ Scrapers

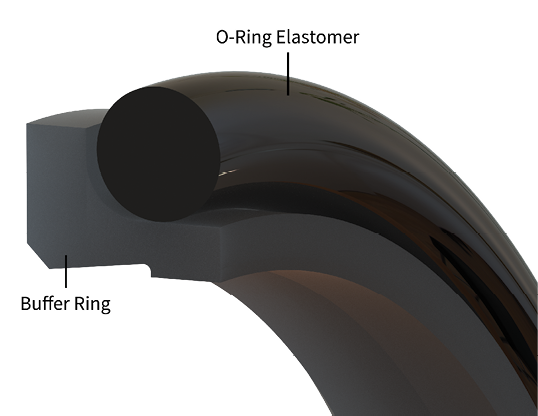

Wipers, excluders, and scrapers are a family of products that are employed on the outboard side of a system.

Properly employed, they keep contamination from entering the seal chamber and prolong seal life. Many configurations exist, with the deciding factors being the aggressiveness of the media being excluded, installation preferences and allowable friction. The majority of scrapers and excluders are specified for service on rod surfaces in order to keep contaminants that come in contact with the rod from entering the system during the return stroke. Wipers are effective in removing fine particulate or fluid from a shaft. Excluders may be engaged to keep road dirt out of a shock or mud out of braking system. More aggressive scrapers might be used to keep ice out of a bridge cylinder or remove slag from a from a foundry lift rig. Excluders can also be chosen that have a dual functionality of keeping contaminants out, while providing redundant sealing of media.

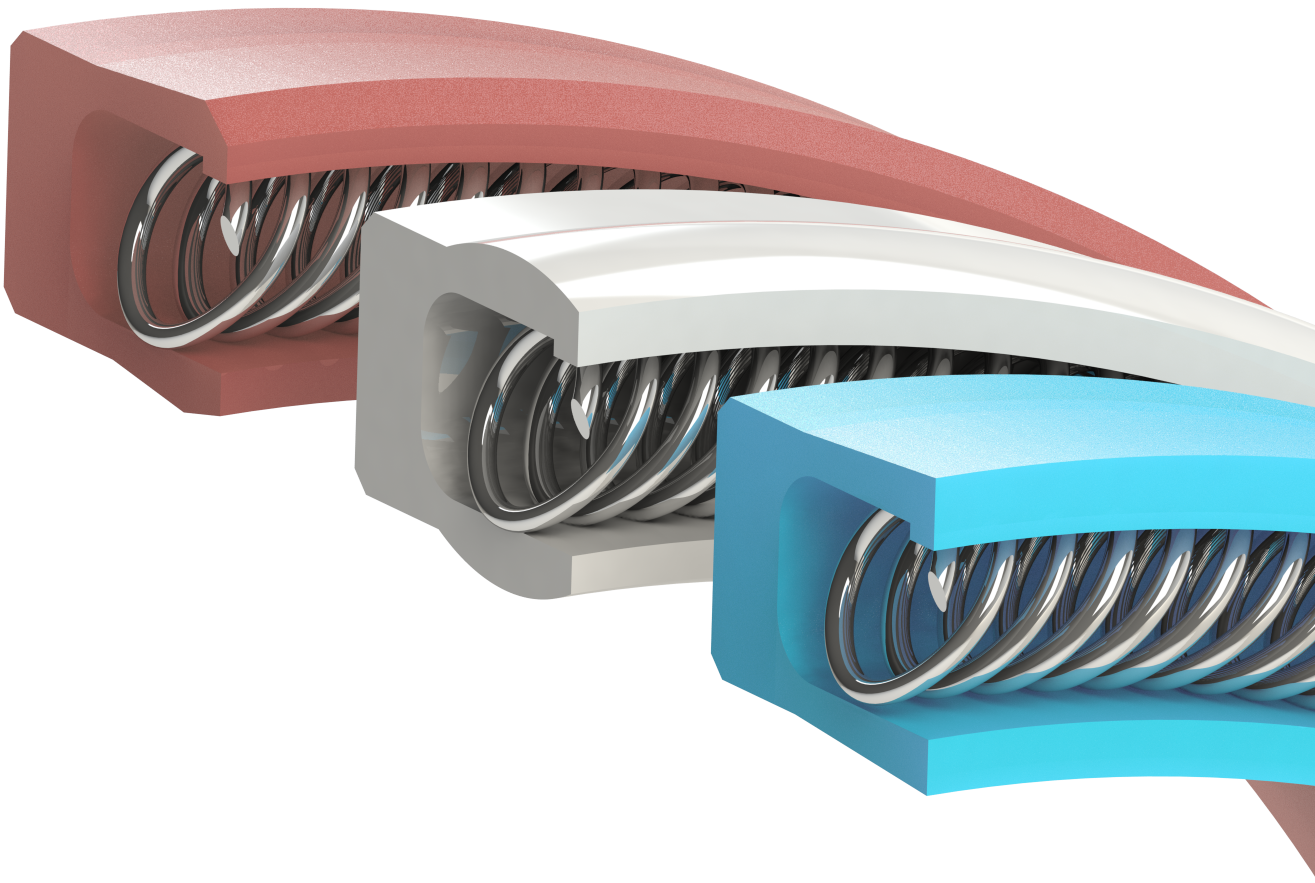

Eclipse wipers utilize a split element in conjunction with a garter spring to afford a light loaded positive contact device that offers moderate exclusion of debris. A good selection if low friction and ease of assembly are the main considerations.

Eclipse excluders employ a double contact design. On the outboard side, a distributed contact patch ensures that a positive prevention of contamination occurs. On the inboard side, a high contact load acts as a redundant seal for the media. Energized with an O-Ring, Eclipse excluders effectively separate the working fluid from external contamination.

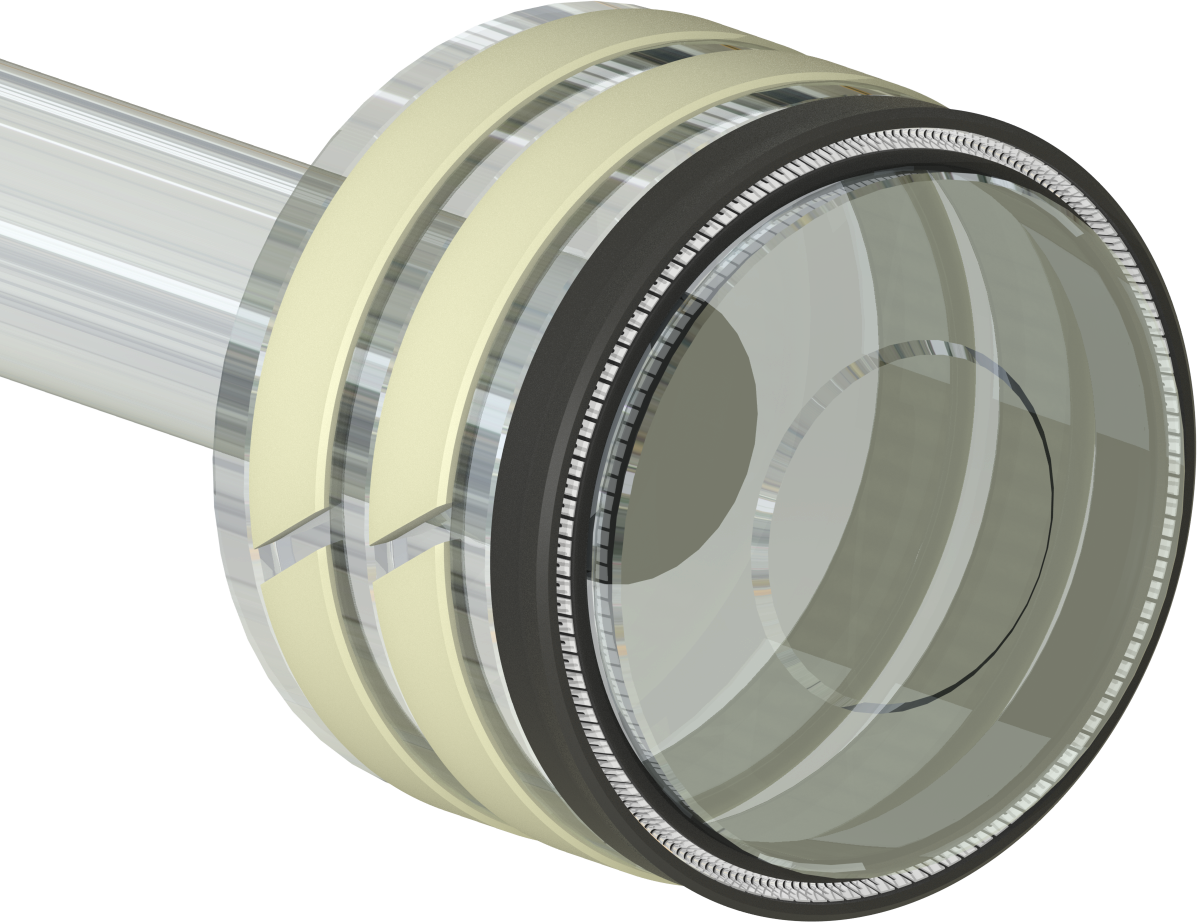

Metallic rod scrapers are the most aggressive design against ingress of contamination. Eclipse Polyflex Metallic Scrapers incorporate a stainless steel scraper ring encased in a PTFE jacket. The soft stainless ring provides maximum scraping effectiveness without damaging the rod. The PTFE jacket centers and seals the scraping ring while allowing radial shaft movement without binding or galling. Unlike a rubber encased scraper, the PTFE jacket will withstand temperatures up to 550°F.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!