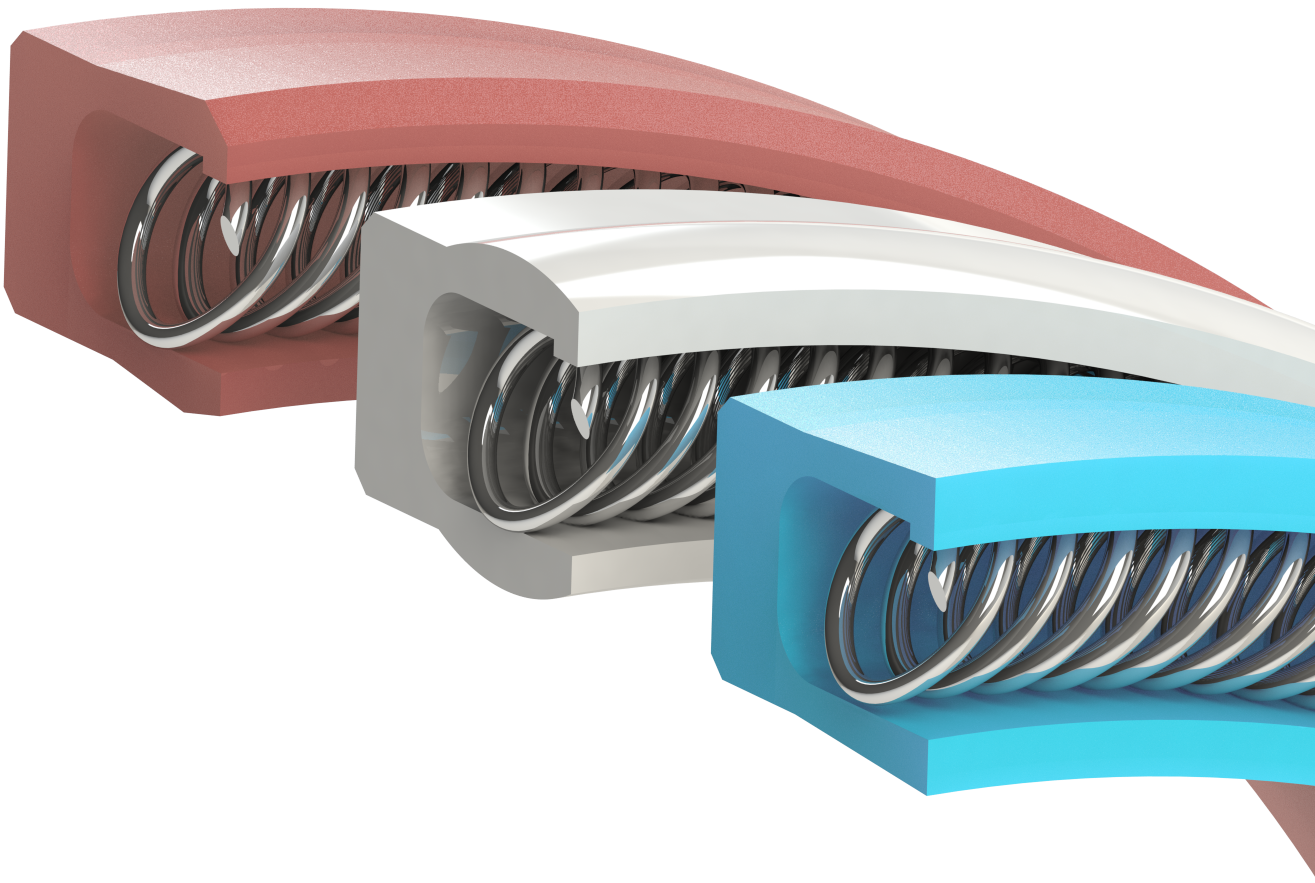

Wear Rings

Wear rings, also referred to as linear bushings, are a support product for Eclipse sealing products.

They can be ordered in a large variety of materials, but typically they are made of high modulus, high wearing materials. Manufactured as split rings to aid in installation, they are designed to carry to load created in hardware situations that involve side loading due to equipment weight, eccentric loading and misalignment. Wear rings are incorporated into seal system designs for two main reasons. First, wear rings prevent metal-to-metal contact from occurring. Secondly, wear rings isolate seal components from uneven loading allowing optimum performance. For these reasons, Eclipse often proposes wear rings in conjunction with seals in order to ensure that the longest seal life and performance is realized.

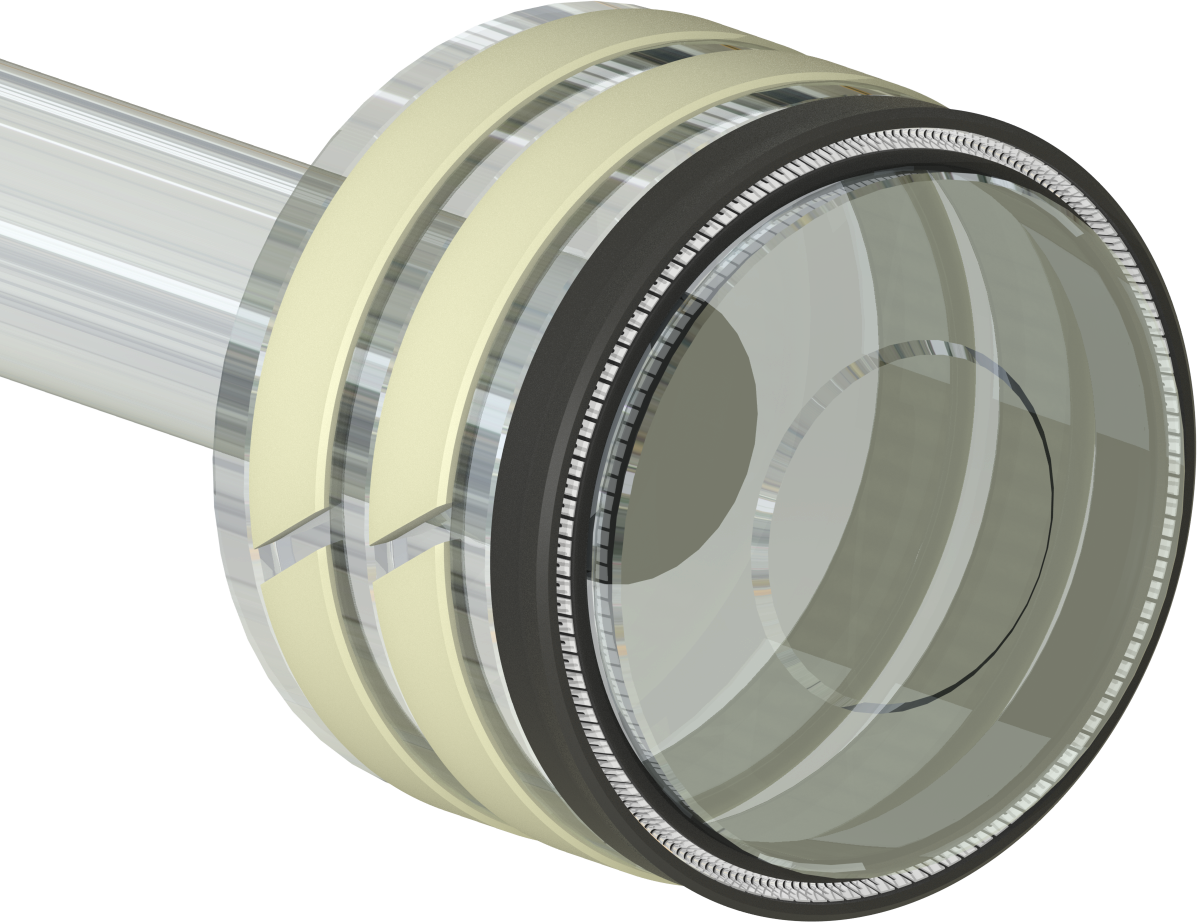

Wear rings can be found in nearly all reciprocating machinery such as hydraulic cylinders, air pumps and shocks. Both rod and piston configurations are available and often both are specified in machine assemblies to maintain smooth predictable performance.

Rod wear rings are essential components that maintain clearance between the rod and rod-bore. In service, reciprocating rods often see side loading or shock loads. Rod wear rings, when designed with proper exposure, absorb these loads allowing seals to function at peak performance.

Piston wear rings are most commonly installed on the ends of a reciprocating piston and maintain the running clearance gap. In service, a wear ring will limit unwanted movement of the piston in order to avoid metal-to metal contact. Additionally, by guiding the piston, optimized seal performance is realized.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!