Aerospace

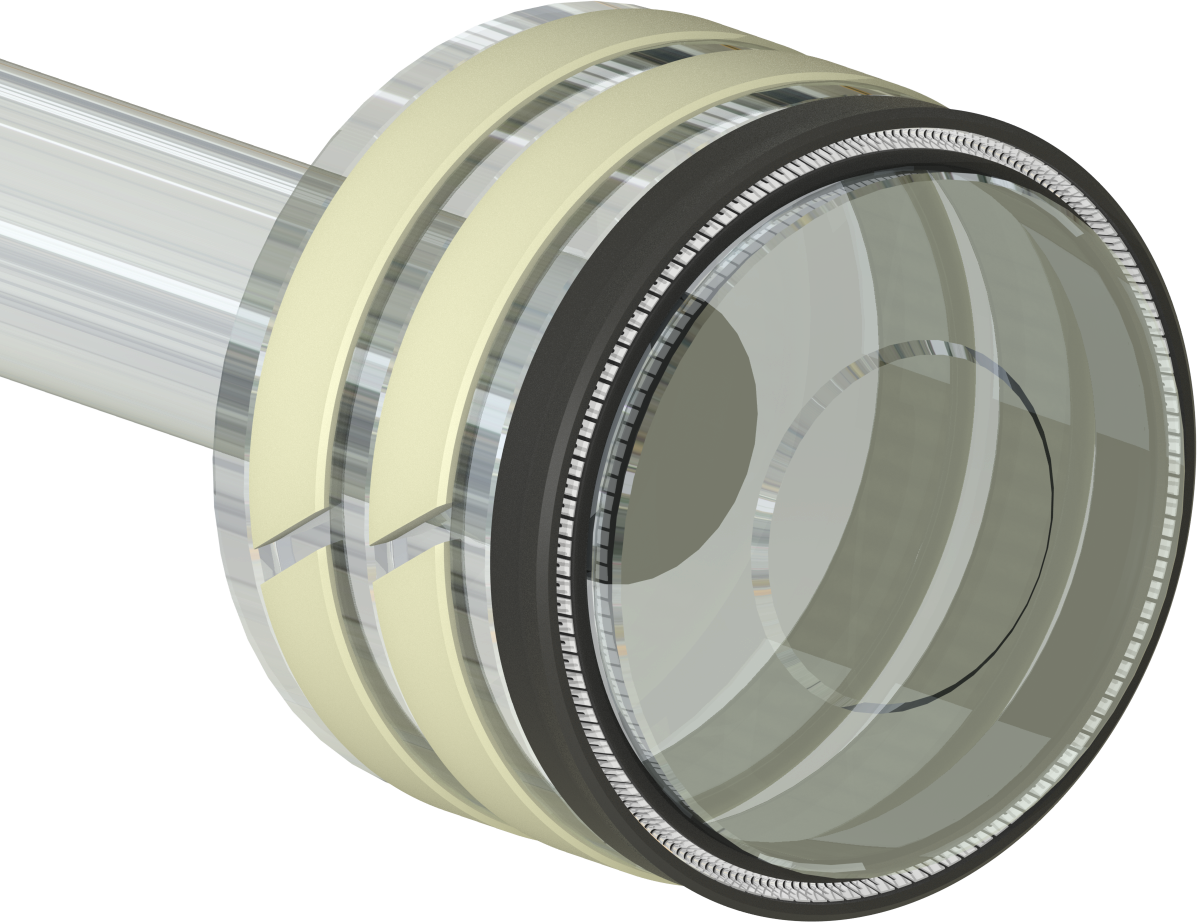

Eclipse produces high-precision seals for the aerospace industry, including high performance seals for extreme aerospace environments.

Applications include aircraft braking systems, gearboxes, flap actuators, satellites, cryogenic refueling systems, turbo pumps, launch pad dampeners, and armored transporters.

We work with engineers and purchasing staff to understand specific production equipment needs in order to find short lead-time solutions to support your operation.

Defects and failure of aerospace seals are out of the question

With precision Eclipse seals built to your critical specifications, it’s one failure point you don’t have to worry about. We realize that material and dimensional specifications are critical to you, so we use rigorous quality control to deliver meticulously accurate seals.

Let us help uphold your 100% reputation and client loyalty allowing you peace of mind by avoiding operational failure.

Resilient and reliable materials withstanding extreme demands

By using high-end materials with agile in-house manufacturing, Eclipse can cost-efficiently produce long-lasting aerospace seals for a variety of applications with high demands. Requirements include wide temperature ranges, pressure extremes, aggressive chemicals, and the harshest conditions.

Full AS9100 quality certification with fully transparent and accountable documentation

With AS9100 certification, Eclipse has been specified on a large number of source control drawings. Our complete supply chain is AS9100-compliant for seamless consistency end-to-end. If any newly required material can’t be sourced from an existing AS9100 company, a rigorous testing and documentation regime will be applied to bring them up to standard.

Eclipse is ITAR registered to ensure correct traceable document protocol for your Defense and Government contracts. This includes a complete history of the project through our document retention policies.

All the engineering support you need to develop cost-effective new technology and applications

We’re happy to look at different materials, designs, and options to develop cost-effective seal solutions to support your aerospace systems.

We’ll make seals exactly the same way for the life of your products to ensure 100% performance reliability. If this is not possible due to changes outside our control, we’ll go through the rigorous process of testing and certification for equivalent or superior functionality.

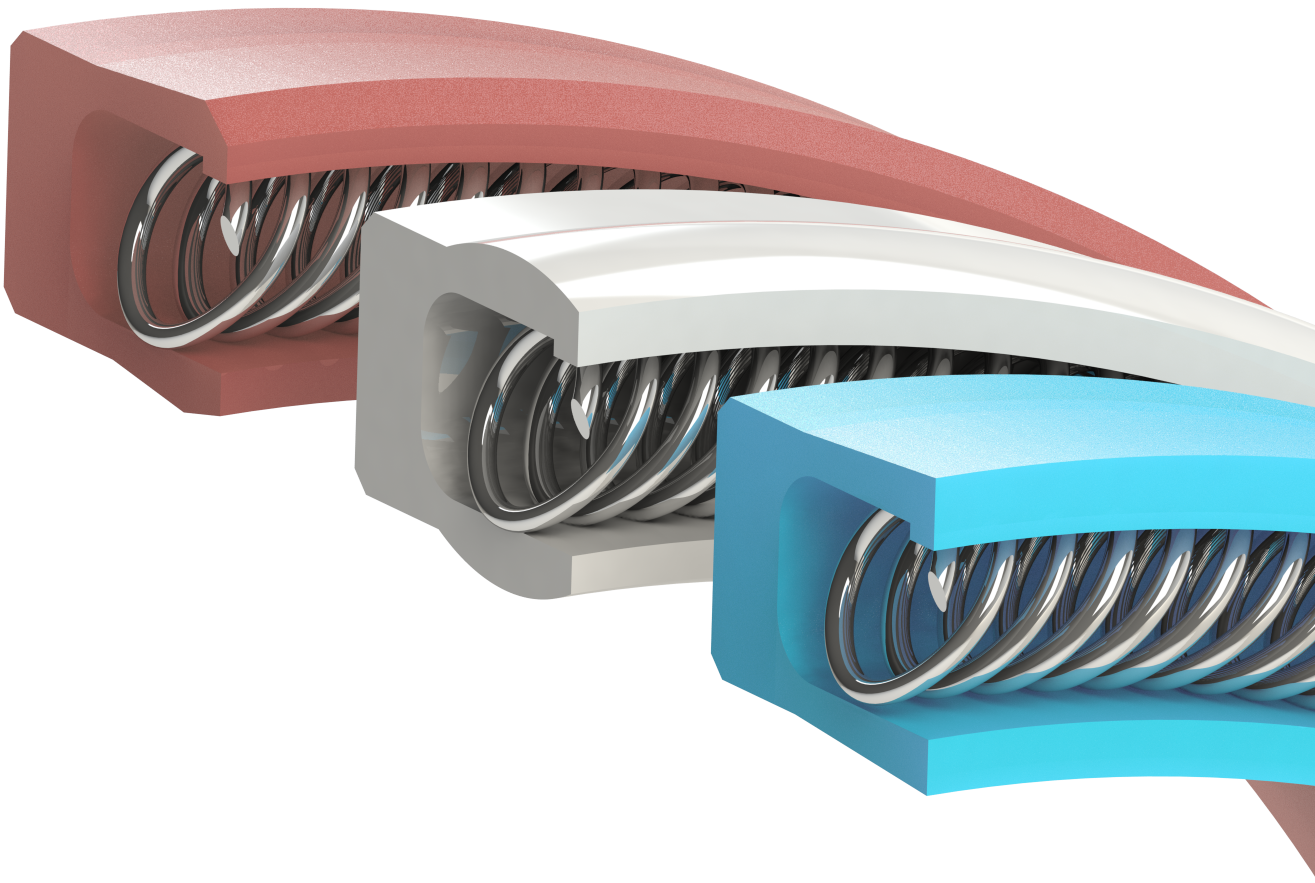

Eclipse seals for the aerospace industry

- Spring-energized aerospace seals

- Elastomer-energized PTFE seals

- High performance elastomeric seals & o-rings

Feel free to tell us about your unique requirements and we’ll let you know what we can do for you.

Or you can find out more about us, our products, or materials.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!