PTFE | ET

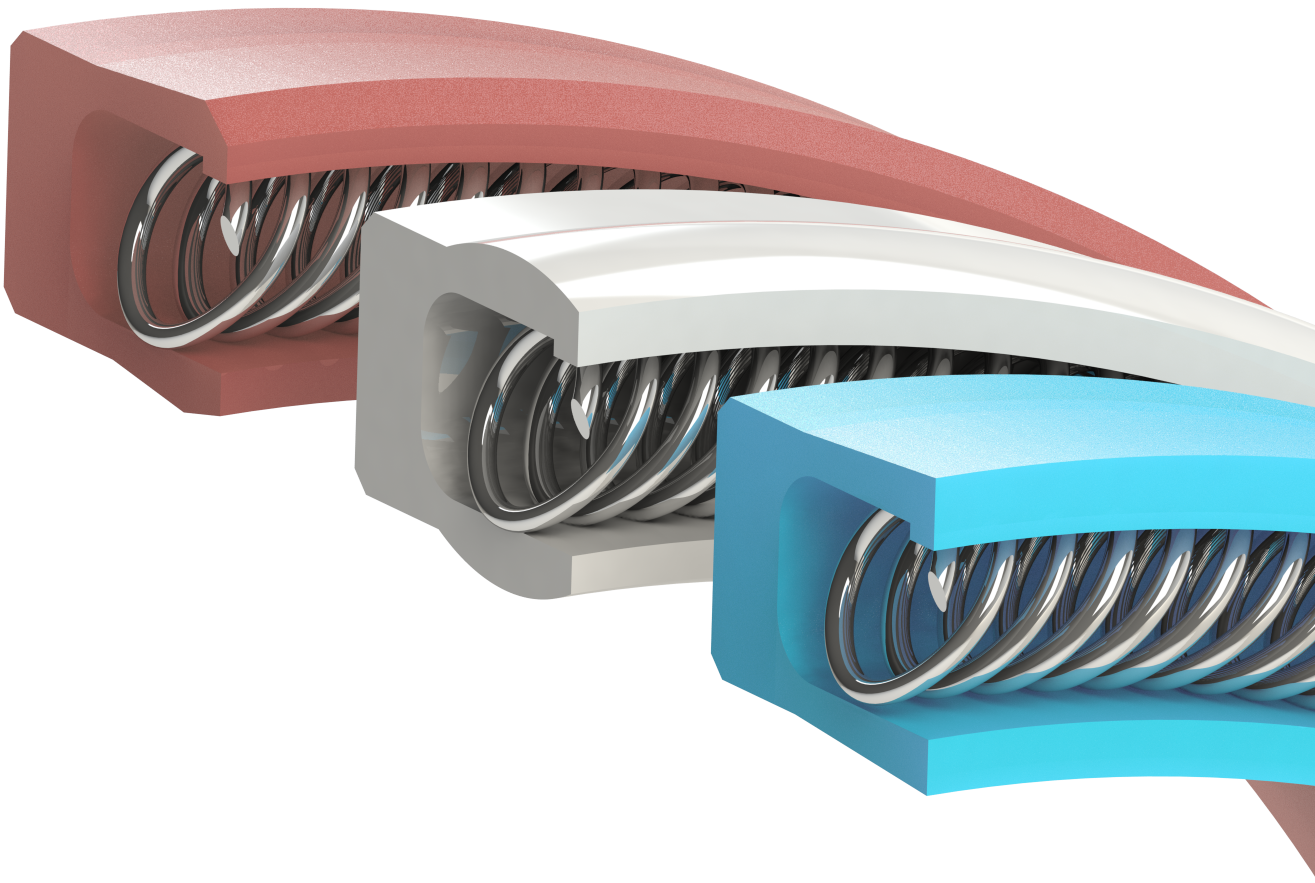

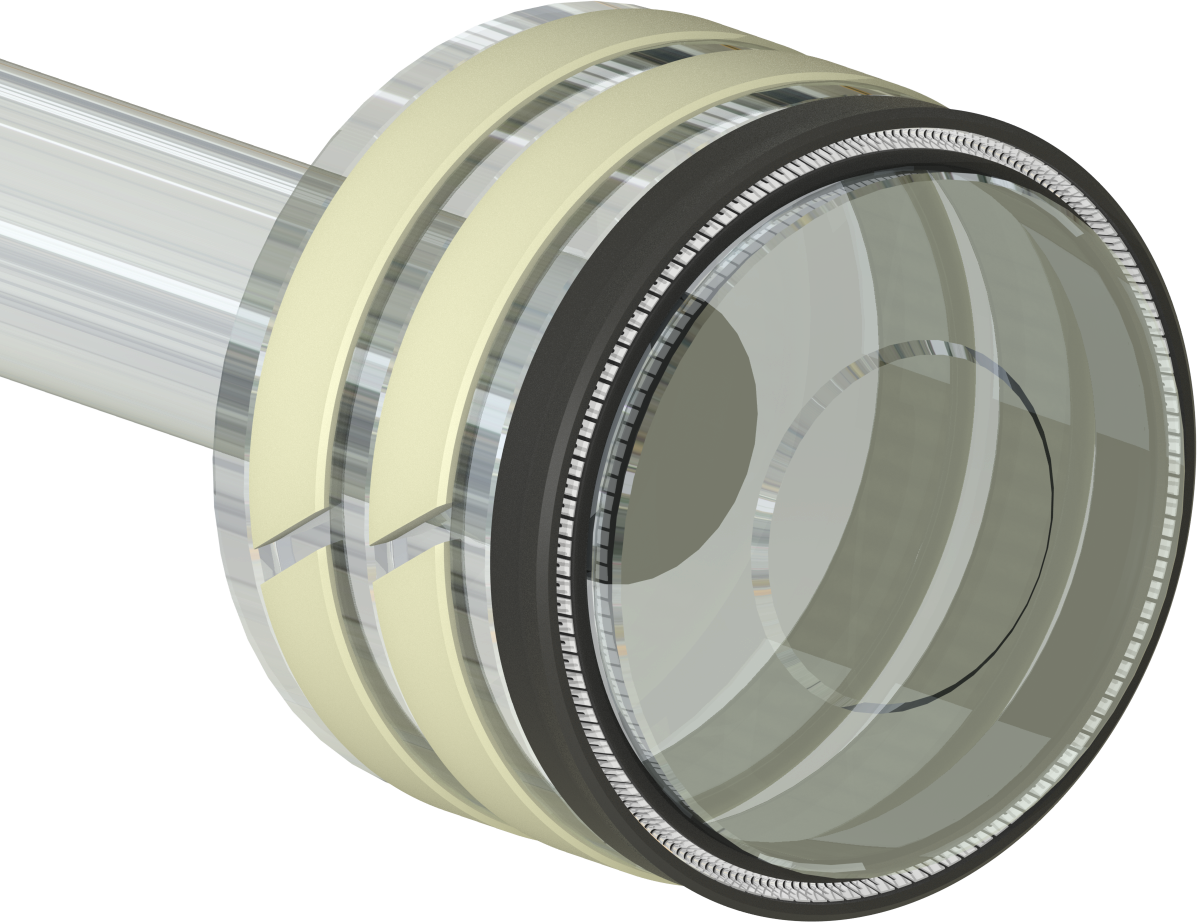

Eclipse ET materials are a range of materials based on PTFE resin. Most notably known as DuPont® Teflon, PTFE (Polytetrafluoroethylene) makes an extraordinary material for seals because of its chemical compatibility, broad temperature range, and low friction properties. Combining the base resin PTFE with engineered fillers allows a wide variety of blends that can be specified per application. Eclipse has over 50 ET codes available to optimize any seal design.

ET materials are a common replacement for standard elastomeric products in industries such as Downhole, Semiconductor, Epoxy and Paint systems where resistance to harsh chemicals is mandatory. PTFE is inert to nearly all substances and is only known to react with a few chemicals at high temperature.

Parts manufactured from PTFE resins exhibit high strength and toughness at cryogenic temperatures down to -450°F (-268°C). This makes it the material of choice when considering applications such as medical (MRI) equipment, food freezing machinery and liquid cryogen fuel systems that utilize valves and couplers. At the other end of the spectrum, filled PTFE blends can operate up to 575°F (302°C) continuously, making it a prevalent material choice for high temperature valve seats, power transmission assemblies, process ovens and foundry equipment.

Perhaps the best known attribute of PTFE is its exceptionally low friction properties. PTFE based materials exhibit a fraction of the friction of many other common seal materials such as rubber and urethane. This makes it an excellent choice for applications that have poor lubricity, strict power requirements and/or the need for smooth (non stick-slip) operation. For rotary power equipment, such as generators, gear pumps, and compressors, this is especially important, as any heat generated from friction robs power form the system and ultimately leads to heating the seal element inducing high wear. With Eclipse ET materials, effective seals can be made to handle high pressures and velocities. Several new technologies run on small motors with battery power. In such cases, ET materials are the logical choice to optimize seal performance at the lowest friction possible to increase battery life. In this way, Eclipse ET materials have found their way into medical and analytical devices such as surgical equipment and high pressure liquid chromatography. Aerospace is another industry that has benefited greatly from PTFE based materials. Flap actuators, control cylinders, braking assemblies and auxiliary power units are a few of the applications that necessitate the use of ET materials.

Available Materials

Virgin PTFE, unfilled grade used primarily in static applications. Offers high elongation compared to filled grades of PTFE which makes it suitable for gas sealing and cryogenic applications. Can also be specified in food contact applications. Not recommended for bearing load applications.

Pigmented version of ET000. Used for identification purposes as well as static and light duty applications.

PTFE with Lamellar MoS2 additive

PTFE with the addition of graphite filler. Graphite imparts wear resistance and lubricity allowing for specification in moderate duty applications.

PTFE with the addition of a small amount of carbon powder. Carbon filler is used when the intrinsic properties of PTFE are desired, along with additional wear resistance. Carbon powder is readily dispersed in PTFE assuring homogenous properties.

PTFE with the addition of a moderate amount of carbon powder. Most commonly specified in light duty applications.

PTFE with the addition of a medium amount of carbon powder. Suitable for medium duty reciprocating and rotary applications.

Glass fiber filled PTFE. Short length glass fibers are added when compressive strength and resistance to creep are a consideration. Glass filled compounds are not recommended as seals on unhardened surfaces.

A higher filled version of ET007. Commonly used for back-up rings and valve seats.

A high fill PTFE blend with carbon and graphite suitable for a wide variety of components including seals, wear rings, scraper seals, back-up rings and thrust washers.

Bronze filled PTFE. Bronze powder significantly bulks up PTFE allowing for bearing, wear-strip and scraper seals applications.

Bronze filled PTFE. Higher filled version of ET010.

PTFE blended with fiberglass and MoS2. This blend offers the lubricity of ET002 combined with the increased wear and extrusion resistance afforded by the addition of glass fibers. Utilized in a wide variety of dynamic applications when used on hardened surfaces.

PTFE blended with fiberglass and MoS2. High pressure-velocity capable version of ET012 due to a larger amount of glass filler. Also used in high temperature applications.

PTFE with polyimide reinforcement. One of several high modulus polymer filled compounds. This low filled option is useful in applications running on stainless steel (soft) mating surfaces. Polymer fillers are less aggressive than fiber and mineral fillers. Polyimide filled PTFE can also be used when contact with food or pharmaceuticals is anticipated.

Glass fiber filled PTFE. Similar to ET007, with red pigment for identification purposes.

PTFE with aromatic polyester reinforcement. A polymer filled compound that is considered when abrasion to mating surfaces is a primary concern.

PTFE with aromatic polyester reinforcement. A higher filled version of ET016 for greater wear resistance.

PTFE with mineral filler. Mineral filler adds wear resistance and is a common upgrade from virgin PTFE, when FDA compliance is a requirement.

Highly filled PTFE with PPS, Carbon and MoS2. Used in demanding applications where ultimate product life is the primary selection criterion.

Carbon Fiber Blended with PTFE. Carbon fiber greatly improves rigidity of PTFE which has lead to this compound being utilized in back-up rings and wear rings in addition to sealing components.

PPS and carbon filled PTFE. High level of PPS filler makes this material one of the higher wear resistant grades of polymer filled compounds.

Highly loaded PTFE with Glass, Nickel and MoS2 fillers. Used in specialty applications.

Carbon Fiber Blended with PTFE. A lower filled version of ET020, utilizing the reinforcing properties of carbon fiber while maintaining reasonable leakage control in loaded sealing elements.

PTFE with polyimide reinforcement. Higher filled version of ET014.

Notice:

Technical Information, test data and advice provided by Eclipse Engineering are based on information and tests we believe to be reliable and are intended for persons with knowledge and technical skill sufficient to analyze test types and apply adequate safety factors for the given application. Because actual application conditions vary widely, these values are intended for comparitive purposes only and the suitability of this material is ultimately left to the end user.

ET000

Eclipse premium grade virgin PTFE. As an unfilled material, ET000 offers the best flexibility and sealing characteristics as compared to filled grades. As such, ET000 is commonly used in applications that are static or slow dynamic where sealing effectiveness is considered critical over wear or extrusion resistance. Examples would be in soft seats for valves or for face gaskets in flanges. Excellent sealing can be realized in gaseous media when loaded properly as in Eclipse Spring Energized Seals. ET000 maintains elongation properties at extremely low temperatures, and is often used in cryogenic couplers and valves sealing media such as natural gas, nitrogen, oxygen and hydrogen down to -450°F (-268°C).

ET000 is FDA compliant per 21 C.F.R 177.1550. When used under the conditions listed in this specification, ET000 can be engineered into machinery that comes in contact with food substances. Mixing and blending equipment commonly use this grade as well as dairy, food additive and processing industries. For applications that have higher speeds and pressures, consider filled grades such as ET014 or ET018.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 2.16 | (-) |

| Tensile Strength at Break | ASTM D638 | 4500 | psi |

| Elongation at Break | ASTM D638 | 400 | % |

| Hardness | ASTM D2240 | 55 | Shore D |

ET001

Pigmented version of ET000. This is the lightest fill content PTFE that Eclipse offers and is specified when slightly higher abrasion resistance is needed over virgin PTFE. ET001 is an industry standard and is prevalent in hydraulics where O-Ring energized seals such as channel seals are common. The pigmentation used in ET001 allows it to be specified when color code 35275 per FED-STD-595 is required.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.16 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3000 | psi |

| Elongation at Break | ASTM D4745 | 250 | % |

| Hardness | ASTM D2240 | 58 | Shore D |

ET002

With the addition of a small amount for molybdenum disulfide, ET002 allows better performance in friction sensitive applications, especial y in dry-running conditions. Intermittent dynamic assemblies such as encoders, samplers and similar small devices benefit from lip seals manufactured with ET002.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 2.23 | (-) |

| Tensile Strength at Break | ASTM D638 | 4700 | psi |

| Elongation at Break | ASTM D638 | 295 | % |

| Hardness | ASTM D2240 | 58 | Shore D |

ET003

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.13 | (-) |

| Tensile Strength at Break | ASTM D4745 | 2500 | psi |

| Elongation at Break | ASTM D4745 | 175 | % |

| Bulk Density | ASTM D4745 | 559 | g/l |

ET004

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.16 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3800 | psi |

| Elongation at Break | ASTM D4745 | 250 | % |

| Hardness | ASTM D2240 | 58 | Shore D |

ET005

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.13 | g/cc |

| Tensile Strength at Break | ASTM D4745 | 3650 | psi |

| Elongation at Break | ASTM D4745 | 230 | % |

| Bulk Density | ASTM D4745 | 400 | g/l |

ET006

The addition of carbon particle filler classifies ET006 as a medium level filled PTFE. As a particle filler, carbon homogeneously disperses in the PTFE matrix imparting wear resistance while still maintaining the majority of the virgin resin flexibility. These properties are extremely useful when considering an upgrade from low fill material with minimal compromise in sealing efficiency. As an all around performer in reciprocating and rotary applications, ET006 is a good starting point when specifying a seal material that offers high value performance. ET006 is a common choice for a wide range of applications. It has been used for oven door seals and in rotary manifolds. It has also been used in piston seal hydraulics, shock scraper seals, and stem seals requiring API 6A compliance.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.1 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3300 | psi |

| Elongation at Break | ASTM D4745 | 200 | % |

| Hardness | ASTM D2240 | 62 | Shore D |

ET007

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.2 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3000 | psi |

| Elongation at Break | ASTM D4745 | 200 | % |

| Bulk Density | ASTM D4745 | 60 | Shore D |

ET008

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.22 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3100 | psi |

| Elongation at Break | ASTM D4745 | 210 | % |

| Hardness | ASTM D2240 | 61 | Shore D |

ET009

As in ET006, carbon particle filler imparts wear resistance to this compound. With the addition of graphite, ET009 has the benefit of containing a solid lubricant that becomes valuable when considering a dynamic seal in water service. For this reason, ET009 has been used in the paper and pulp industry for decades. As a high level filled PTFE, ET009 also provides upgrades in temperature and extrusion resistance. Components that undergo temperature, speed and pressure extremes often benefit from ET009 properties, most notably in compressor rings and poppet valves. Because ET009 is a highly filled compound, it can also be specified for low friction linear wear rings where increased compressive strength is desired.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 2.04 | g/cc |

| Tensile Strength at Break | ASTM D4745 | 1900 | psi |

| Elongation at Break | ASTM D4745 | 120 | % |

| Bulk Density | 285 | g/l |

ET010

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 3.13 | g/cc |

| Tensile Strength at Break | ASTM D4745 | 3300 | psi |

| Elongation at Break | ASTM D4745 | 250 | % |

| Hardness | ASTM D4745 | 825 | g/l |

ET011

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 3.93 | g/cc |

| Tensile Strength at Break | ASTM D4745 | 3100 | psi |

| Elongation at Break | ASTM D4745 | 210 | % |

| Bulk Density | ASTM D4745 | 1027 | g/l |

ET012

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.23 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3400 | psi |

| Elongation at Break | ASTM D4745 | 270 | % |

| Hardness | ASTM D2240 | 63 | Shore D |

ET013

When hardened dynamic surfaces are available, ET013 offers extended wear life over lower filled compounds. Glass short fibers reinforce the PTFE matrix imparting wear resistance, extrusion resistance and improved high temperature performance. ET013 is utilized in rotary applications, such gear pumps and clutches. In these applications, hardened dynamic surfaces of 65 Rockwell C minimum are required. It is best used in lubricated service, but is capable of running dry do to the additional MoS2 solid lubricant. ET013 is utilized in reciprocating applications where high pressure-velocities are present and makes a good choice for buffer ring seals and other pressure knock-down devices. When used in conjunction with one of the available Eclipse spring energizers, this material makes an excellent high temperature seal as well as an aggressive scraper up to temperatures of 575°F (302°C).

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.27 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3400 | psi |

| Elongation at Break | ASTM D4745 | 250 | % |

| Bulk Density | ASTM D2240 | 63 | Shore D |

ET014

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 1.95 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3000 | psi |

| Elongation at Break | ASTM D4745 | 275 | % |

| Bulk Density | ASTM D2240 | 560 | g/l |

ET015

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 2.04 | (-) |

| Tensile Strength at Break | ASTM D638 | 3300 | psi |

| Elongation at Break | ASTM D638 | 280 | % |

| Hardness | ASTM D2240 | 61 | Shore D |

ET016

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.07 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3300 | psi |

| Elongation at Break | ASTM D4745 | 320 | % |

| Hardness | ASTM D2240 | 59 | Shore D |

ET017

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.10 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3000 | psi |

| Elongation at Break | ASTM D4745 | 280 | % |

| Hardness | ASTM D2240 | 59 | Shore D |

ET018

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.26 | (-) |

| Tensile Strength at Break | ASTM D4745 | 2800 | psi |

| Elongation at Break | ASTM D4745 | 250 | % |

| Hardness | ASTM D2240 | 61 | Shore D |

ET019

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 1.98 | (-) |

| Tensile Strength at Break | ASTM D4745 | 1900 | psi |

| Elongation at Break | ASTM D4745 | 150 | % |

| Bulk Density | ASTM D4745 | 550 | g/l |

ET020

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 2.04 | (-) |

| Tensile Strength at Break | ASTM D638 | 3300 | psi |

| Elongation at Break | ASTM D638 | 280 | % |

| Hardness | ASTM D2240 | 61 | Shore D |

ET021

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 1.95 | (-) |

| Tensile Strength at Break | ASTM D4745 | 2600 | psi |

| Elongation at Break | ASTM D4745 | 290 | % |

| Bulk Density | ASTM D4745 | 345 | g/l |

ET022

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.45 | (-) |

| Tensile Strength at Break | ASTM D4745 | 3100 | psi |

| Elongation at Break | ASTM D4745 | 220 | % |

| Hardness | ASTM D4745 | 580 | g/l |

ET023

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 2.08 | (-) |

| Tensile Strength at Break | ASTM D638 | 3100 | psi |

| Elongation at Break | ASTM D638 | 245 | % |

| Bulk Density | ASTM D2240 | 61 | Shore D |

ET025

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 1.94 | (-) |

| Tensile Strength at Break | ASTM D4745 | 2500 | psi |

| Elongation at Break | ASTM D4745 | 220 | % |

| Bulk Density | ASTM D4745 | 450 | g/l |

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!