Torlon PAI | ED

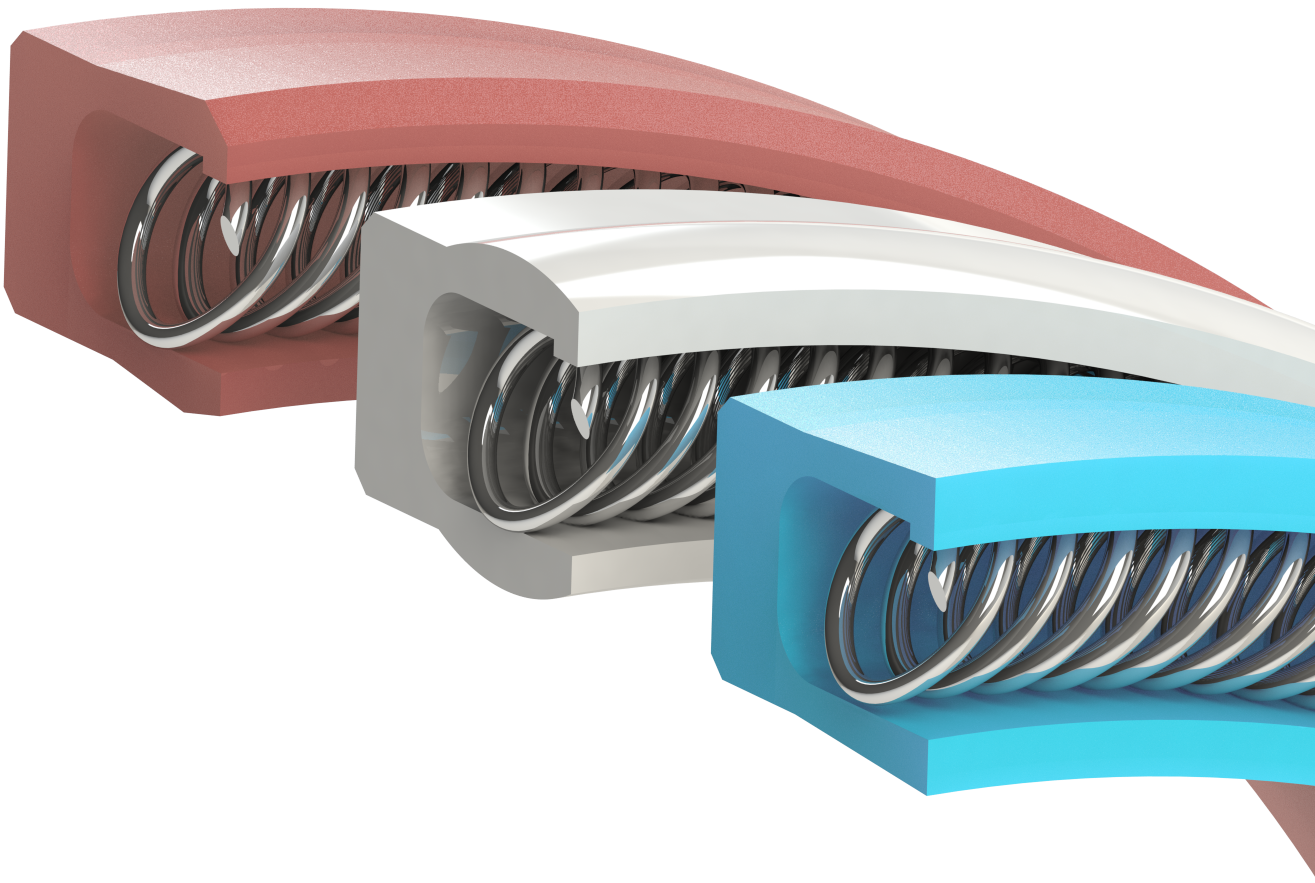

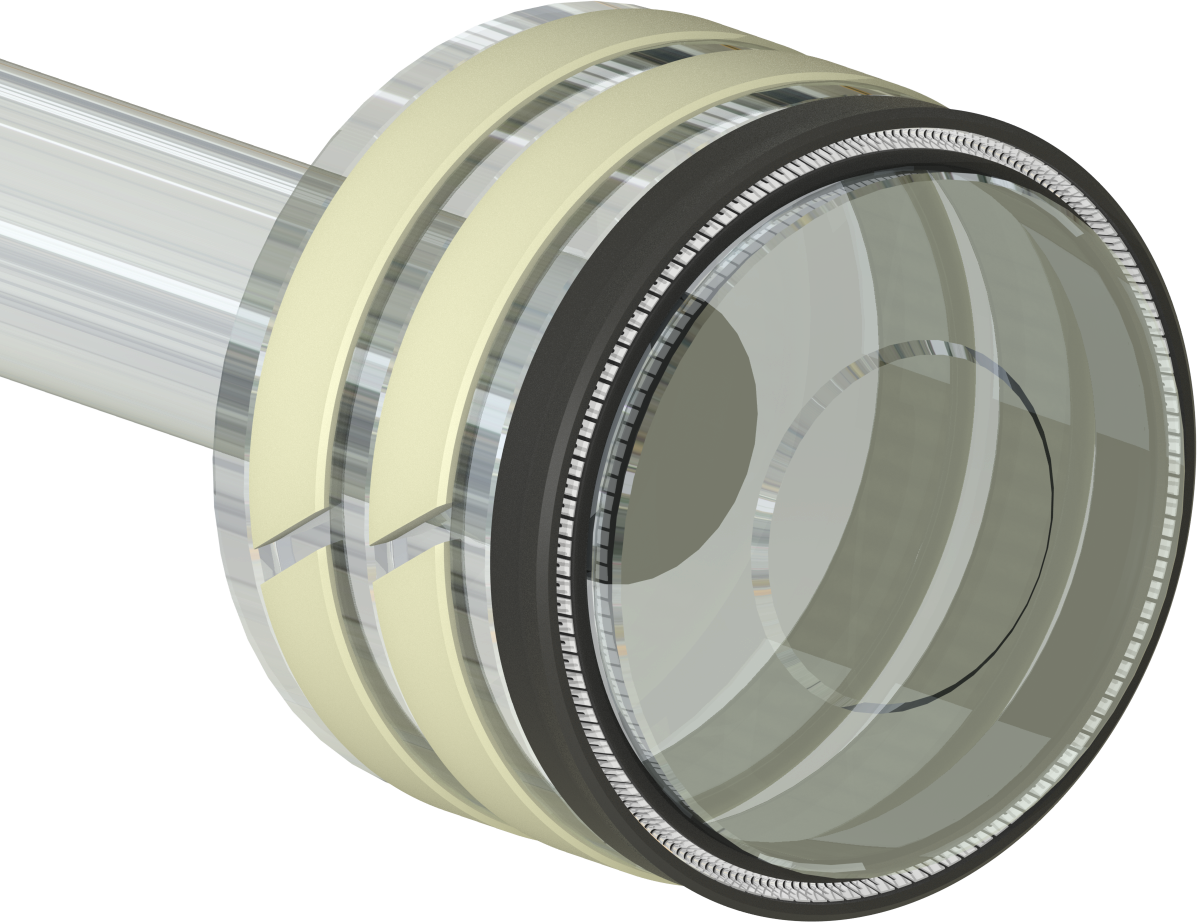

Eclipse ED materials are based on the extremely rigid structure of polyamide-imide thermoset resin. During final processing, the ED material structure is cross linked or imidized. This special processing allows Eclipse ED materials to operate at 500°F (260°C) continuously with minimal degradation of properties. For this reason, ED materials should be considered for parts requiring dimensional stability over a wide temperature range. Several filled grades are available which can be chosen to decrease friction for dynamic applications or to increase compressive strength for load bearing applications. Products such as transmission seal rings, bushings and thrust washers are commonly manufactured with ED materials.

Available Materials

Notice:

Technical Information, test data and advice provided by

Eclipse Engineering are based on information and tests we believe to be reliable and are intended for persons with knowledge and technical skill sufficient to analyze test types and apply adequate safety factors for the given application. Because actual application conditions vary widely, these values are intended for comparitive purposes only and the suitability of this material is ultimately left to the end user.

ED050

Eclipse ED050 is a high modulus non-melting unfilled material. It is the toughest of the ED class materials and will maintain its mechanical properties after thermal cycling. This grade is often used to make insulators and other structural components such as lantern rings and hat support rings. ED050 Manufactured in accordance with AMS3660 and ASTM D5204.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 1.42 | (-) |

| Tensile Strength at Break | ASTM D638 | 18,000 | psi |

| Compressive Strength at Break | ASTM D695 | 24,000 | psi |

| Elongation at Break | ASTM D638 | 8 | % |

| Hardness | ASTM D785 | 80 | Rockwell E |

ED053

Eclipse ED053 is designed to operate in high pressure-velocity applications. The additives are specifically engineered to offer one of the lowest wear rate materials in existence. ED053 is an excellent choice for sliding bearings and bushings that are exposed to high duty cycling. Many ultra-high production volume machines, such as can formers, rely on ED053 to lengthen preventative maintenance schedules. Eclipse ED053 should be considered when challenged with designing a long lasting component under demanding conditions and can be used to fabricate sliding vanes and piston rings.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 1.59 | (-) |

| Tensile Strength at Break | ASTM D638 | 12,500 | psi |

| Compressive Strength at Break | ASTM D695 | 20,000 | psi |

| Elongation at Break | ASTM D638 | 3 | % |

| Hardness | ASTM D785 | 80 | Rockwell E |

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!