ROTARY LIP SEALS

Rotary applications involve a very specific set of requirements that must be addressed in order to ensure a proper seal.

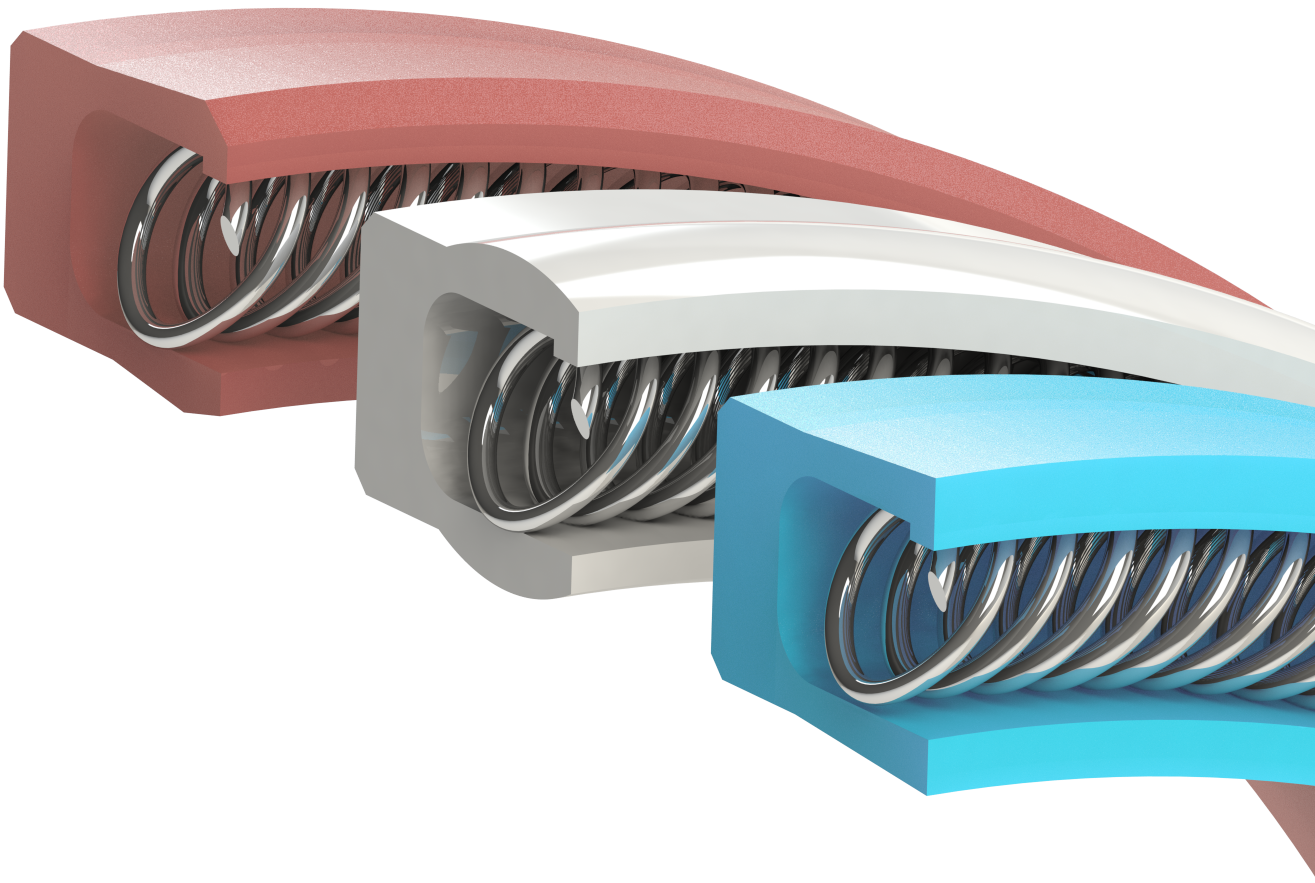

Foremost of these concerns is the ability of the seal to stay stationary in the gland, resisting the rotational forces created from the seal /shaft interface. For this reason, rotary lip seals always employ some sort of anti-rotation feature. This can be in the form of a metal case that gets press-fit at installation, or as an O-Ring that applies gripping friction to the bore. Another consideration in rotary service involves the issue of heat build-up due to friction. In order to make a positive seal, the seal lip must contact the shaft in some fashion. This contact creates friction, which can generate enough heat at high pressures and speeds, that both the seal and the hardware become compromised. Eclipse PTFE based ͞ET materials are utilized for rotary lip seals providing an optimized solution that offers low-friction and long seal life.

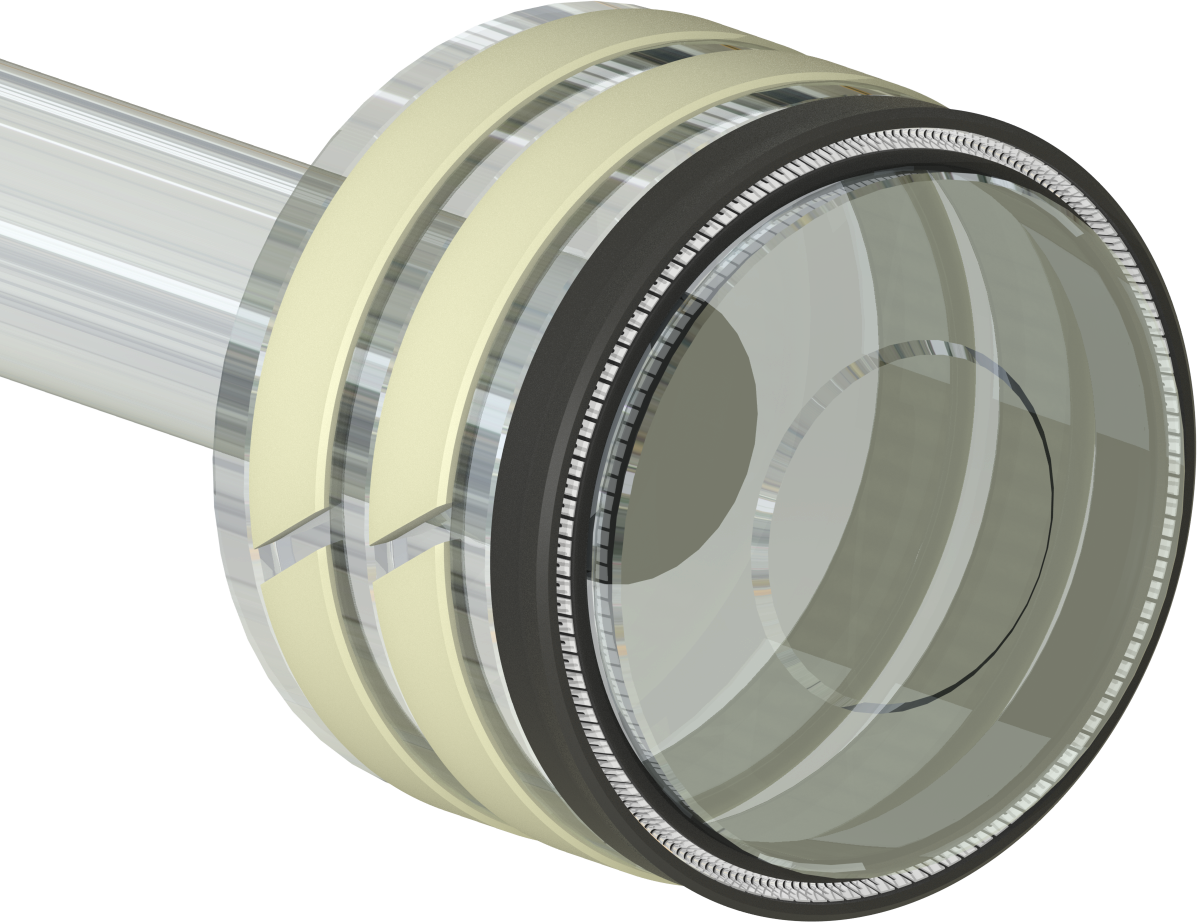

Cased lip seals are the most robust design when considering a rotary seal. Metal-to-metal press-fit ensures that the seal is located solidly in the hardware and provides a tight seal. Additional sealing at the press-fit area can be obtained by adding a spray on seal coat to the OD of the seal. The majority of lip seals operate with media pressure less than 75psi (0.5Mpa). With cased lip seals, the pressure rating can be increased by incorporating extra seal elements and/or using the metal case material to back-up the PTFE seal element. These seals are commonly used in applications sealing oil such as gearboxes, pumps, transmissions and bearings.

For this configuration, anti-rotation is achieved by using an O-Ring to create a frictional interface between the seal and bore. Although a metal cased lip seal has higher pressure and speed rating, an O-Ring OD lip seal is a good choice economically when application parameters permit. Lower use applications such as food processing equipment, pharmaceutical equipment and environmental shaft excluders can benefit from this design. For friction sensitive applications, a lip seal with O-Ring OD should be considered. In service, a lip seal will experience a short period of break-in, after which time the seal element will reach a steady state condition. This steady condition allows very low, very consistent friction equating to low power consumption and heat generation.

The MicroLip is a special class of rotary lip seal, manufactured exclusively by Eclipse Engineering. It takes the industry accepted features of a metal case and spring loaded lip, but is unique in manufacturing process. By utilizing high-speed turning centers, components are precision machined allowing for quick turns on prototypes and small runs as well as allowing design flexibility to fit into reduced hardware cross-sections. Manufactured with Eclipse ET sealing materials, the MicroLip offers the highest PV rated seal possible in the smallest design cavity.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!