Full service seal & bearing engineering, manufacturing and distribution.

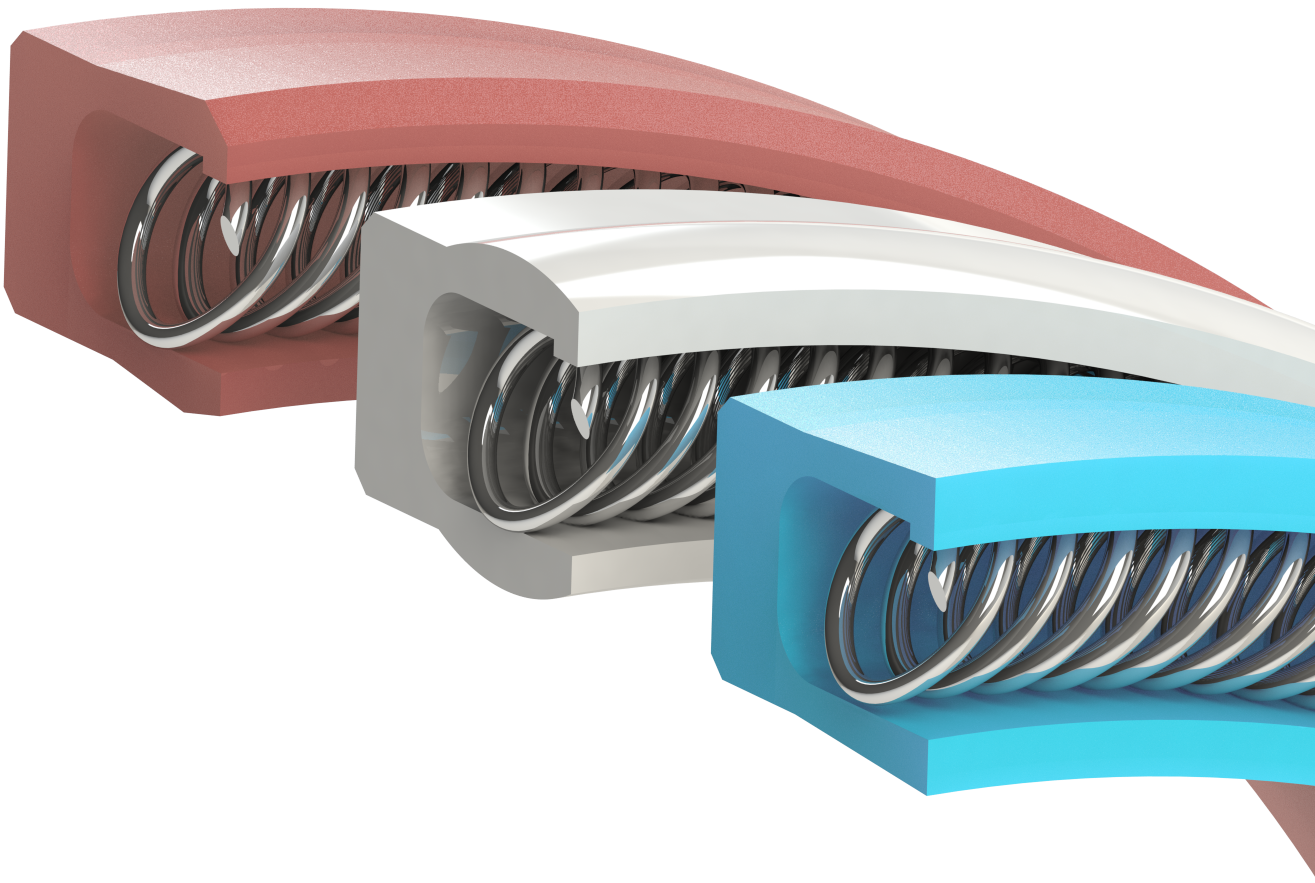

For seals and bearings to work correctly, they need to fit correctly.

With Eclipse Engineering, you can have your bearings, seals, and shapes designed and manufactured in one place, ensuring the perfect fit. Let us show you what the highest level of engineering support looks like.

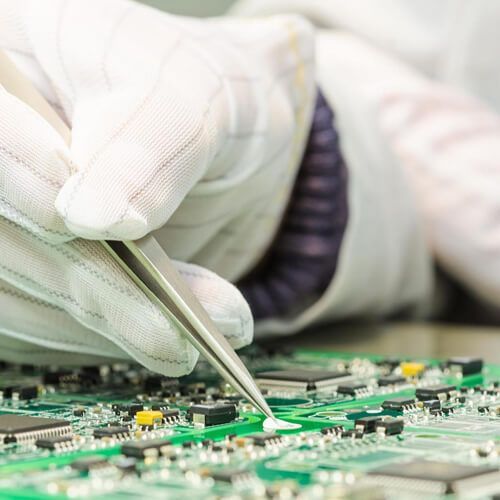

WE DESIGN, MANUFACTURE, AND DISTRIBUTE

You can find the products we design, manufacture, and distribute all over—and even off—the planet

Eclipse Engineering was the brainchild of a passionate, business-minded engineer. His goal was to provide answers to seal and bearing questions to a niche market. Since operations began in 1999, Eclipse has evolved into a comprehensive partner for many OEM, MRO and industrial customers around the world. These companies have come to count on our engineered solutions, problem solving skills, in-house manufacturing capabilities and the responsiveness associated with distribution.

Our staff has more than 200 years of combined seal and bearing experience. This experience allows us to determine if a standard off the shelf product can be used or if an engineered solution will be required for an application.

At Eclipse, we've designed seals:

- In reciprocating, oscillating, rotary and static applications

- That work in applications in excess of 500K PV

- To maintain extreme vacuum

- To withstand 100K PSI

- To contain radioactive water, fire resistant hydraulic fluid, H2S, solvents, and more

As a top tier supplier, we strive to continually improve our processes, while keeping with the essential principle of providing, foremost, engineering and technical assistance that results in an optimized solution for your sealing application.

From our sales professionals to our engineers, we take pride in the fact that we listen to our customers' needs and provide them with quality products—at a competitive price, in a timely manner.

WHAT OUR CUSTOMERS HAVE TO SAY

When it comes to engineering and manufacturing seals, customer satisfaction is everything. From initial communications to the quality of the products we deliver, we always aim to be the best. Want proof? Read what some of our customers have to say about working with us!

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!