Case Study: The Manufacturing Challenges of Tiny Spring Energized Seals

Eclipse is challenged daily by applications pushing the limits of seal design and integrity. Whether it be ultra-high pressure, excessive surface speed, or extended wear-life (or all the above), the pursuit of better sealing performance never ceases.

But Eclipse also is frequently presented with applications challenging not because of their extreme operating conditions, but rather the physical size of the seal and hardware envelop. Eclipse has in-house capabilities to manufacture seals up to 55 inches in diameter, and over 100 inches through production partners.

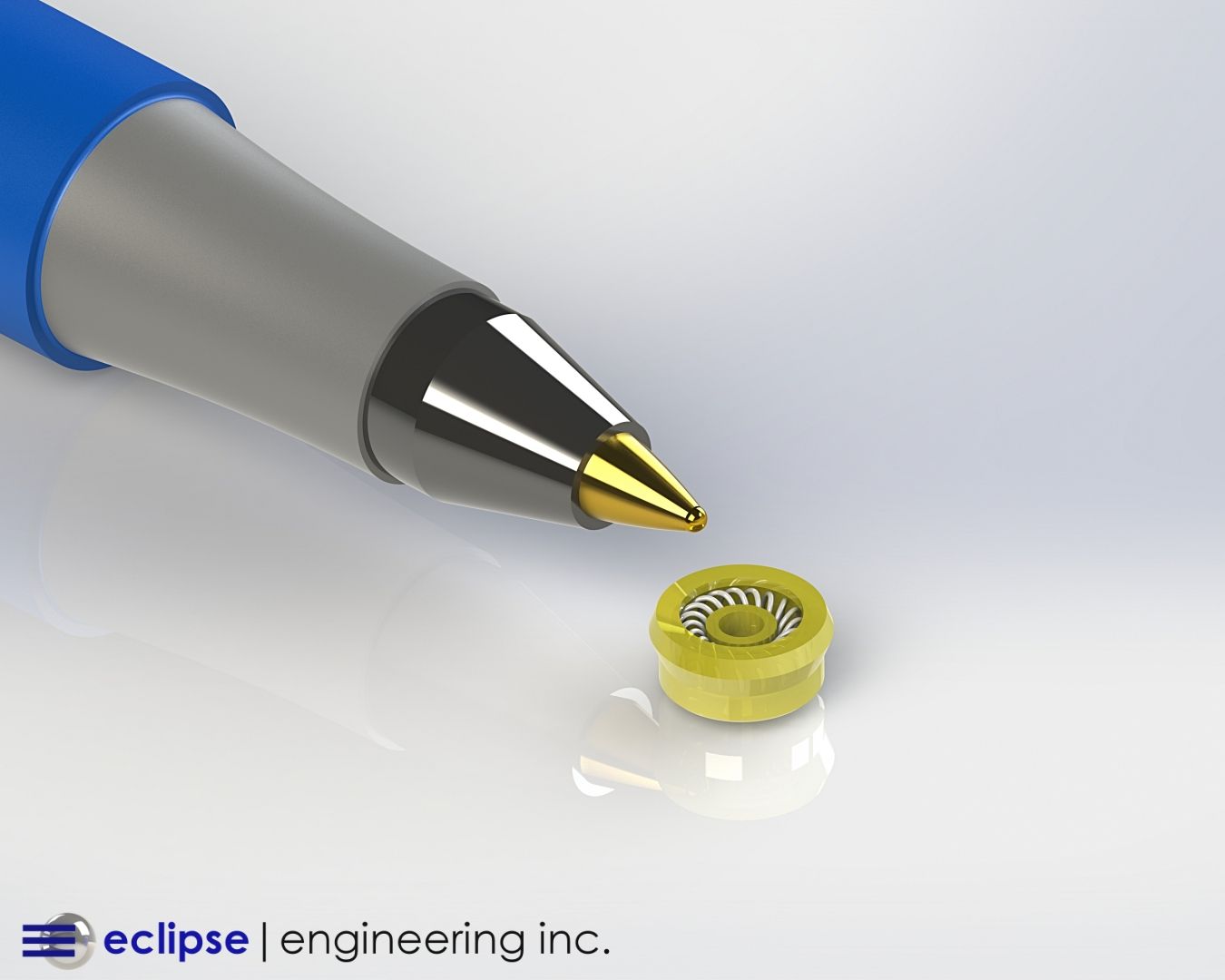

While seals with huge diameters certainly grant their own significant levels of intricacy, here we’ll look at the other end of the spectrum – the micro-sized seals. And not only a simple seal ring, an inherently more complicated and geometrically detailed spring energized seal. As we’ll see, very small diameters make multiple manufacturing aspects more involved and challenging.

The Client's Issue

Eclipse was approached by a customer looking for a sealing solution in their epoxy dispensing equipment. They needed an effective seal for the reciprocating rod responsible for the flow-control and metering of the epoxy while being dispensed.

Operating Conditions:

Reciprocating Rod Seal

Epoxy Dispensing Head

Rod Diameter: 1.2mm [0.047”]

Stroke Length: 6mm [0.236”]

Cycle Rate: 15 per min

Media: Epoxy

Operating Pressure: 1,500 PSI

Temperature: 70° to 150°F

Sealing Epoxy has its own set of difficulties, but Eclipse supplies numerous successful sealing solutions to applications such as this across the industry. A set of design and manufacturing principles has emerged from Eclipse’s years of experience developing seals for thick and viscous media.

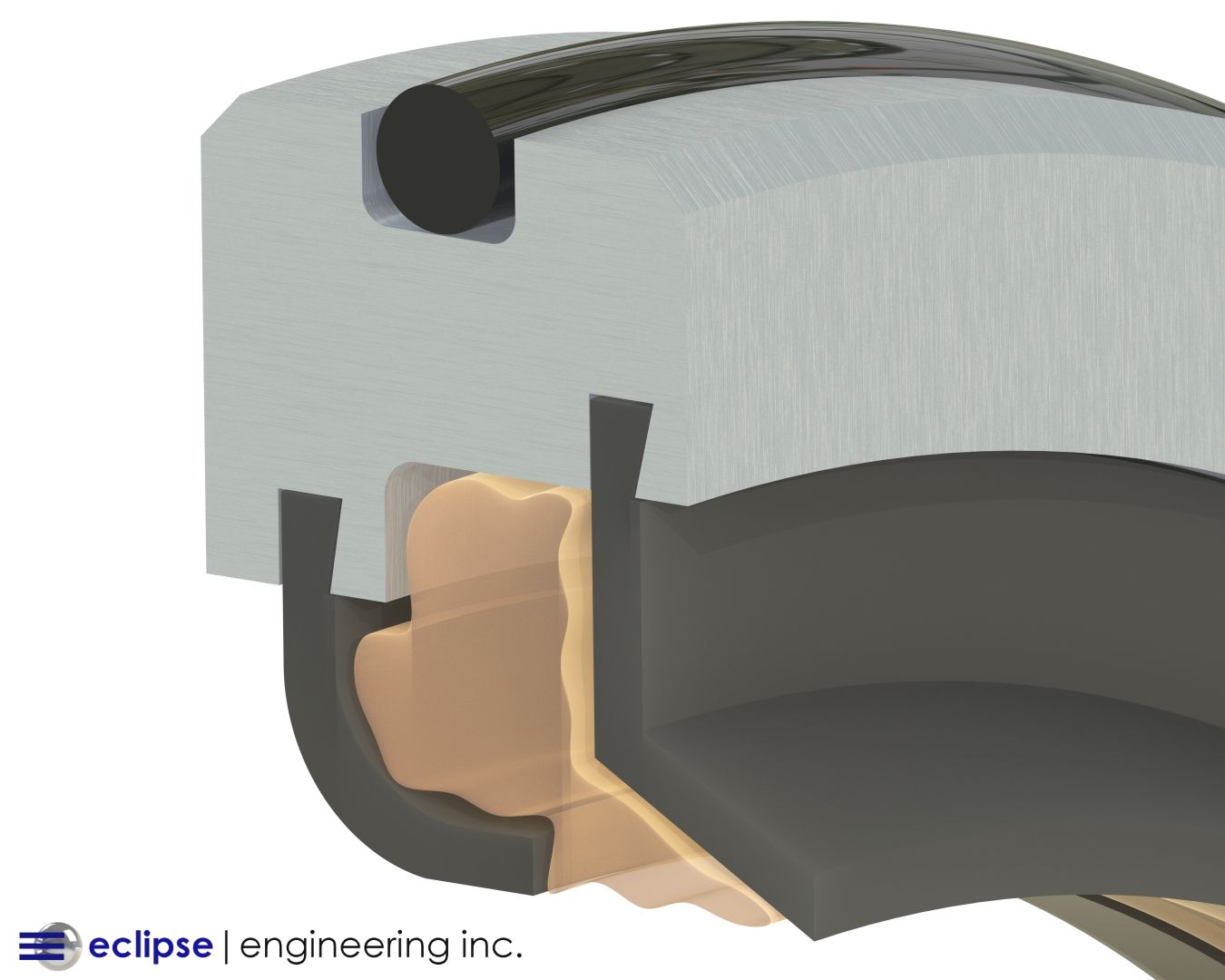

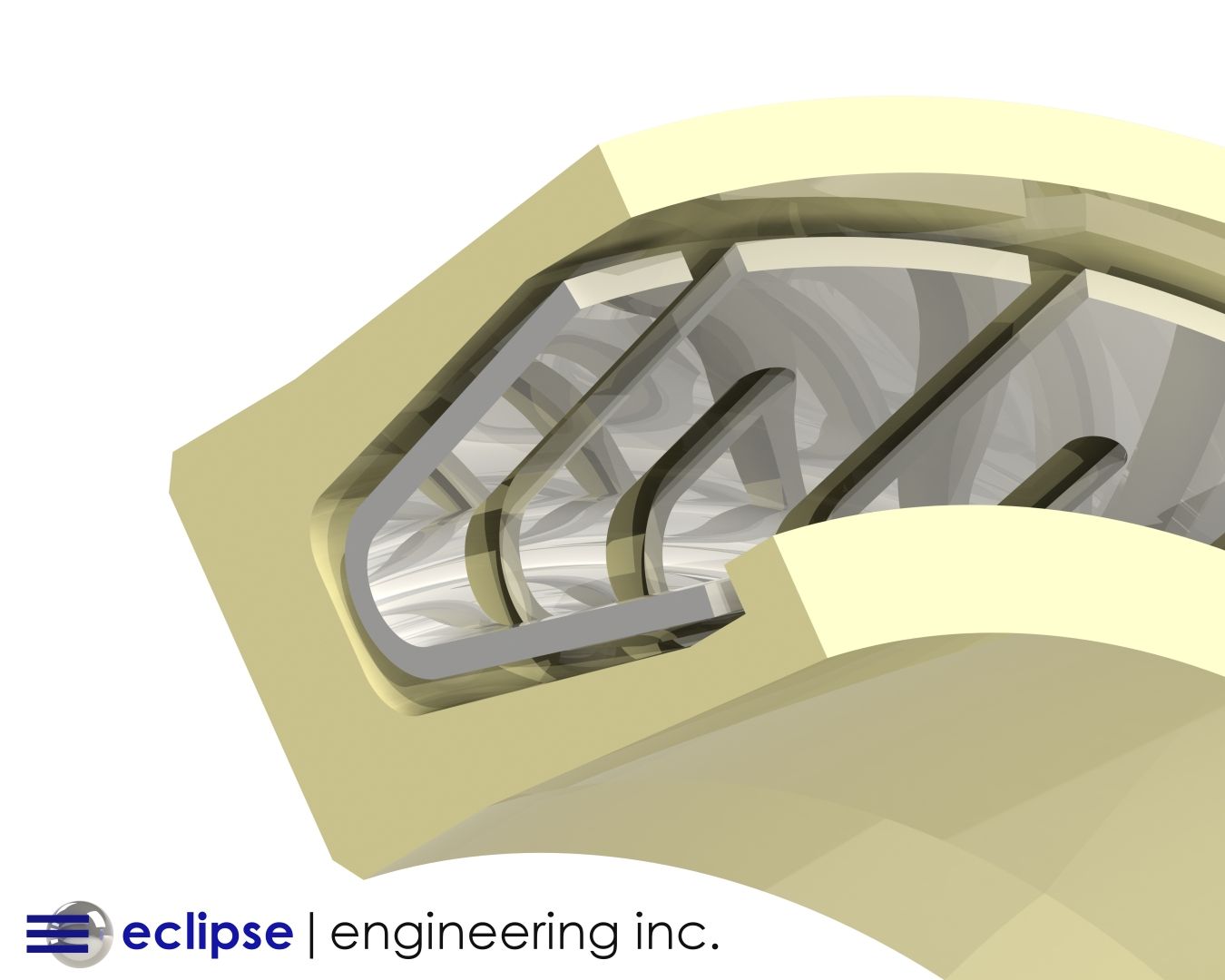

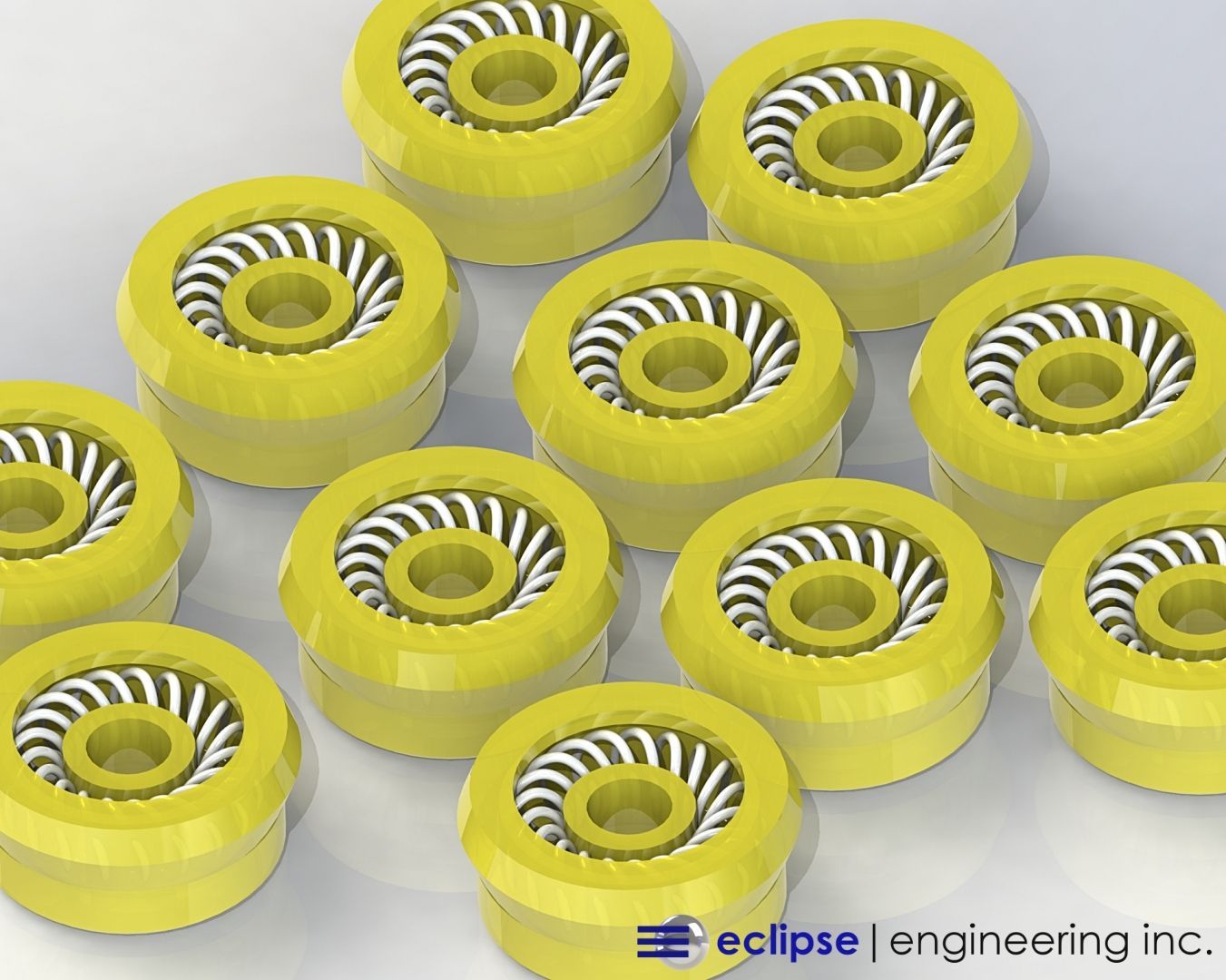

In general terms, most viscous media sealing solutions have three things in common: A variant of UHMW for the seal jacket, heavy spring loading, and multiple point contacts with increased interference. In most cases, multiple nested V-Springs are incorporated to provide optimal load and energize the compound contact points on the seal.

With this formula, Eclipse has had great success sealing media like epoxy, urethane, silicones and acrylics. The heavy loading is necessary to effectively wipe the reciprocating rod. This is balanced with the correct material and design geometry to also provide long wear life of the seal, which has the potential to be compromised under such loading.

Eclipse’s challenge in this case was to incorporate these same proven principles in a micro-sized seal.

The Eclipse Solution

Eclipse knew immediately that the size limitations would not allow the typical viscous media design elements to be employed, and therefore different methods would need to be used to accomplish the same tasks.

Starting with the spring, it was easily apparent that cantilever V-Spring would not be an option. At this pin-like diameter, the tabs of even zero series spring would be overlapping on the inner diameter once the spring was wrapped into a circle.

A way to avoid this would be to have a specialty die made to stamp and form the V-Spring. The inner diameter tabs could then be tapered to avoid overlapping. But at the modest quantities the customer was requesting for the seals, the very expensive die tooling would not make financial sense.

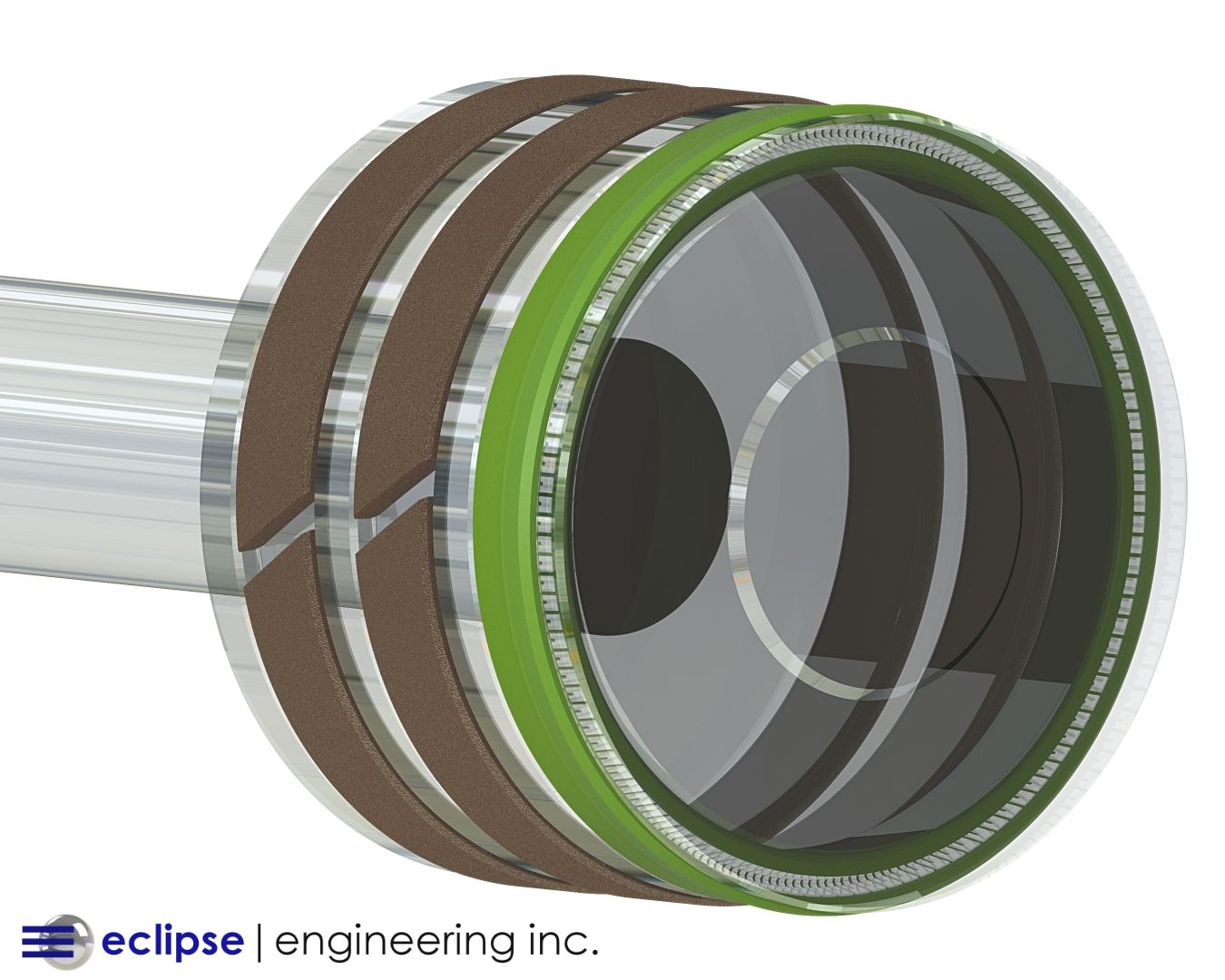

Eclipse knew they would need to use Canted Coil spring. Canted Coil would not have the same problem as V-Spring, it could be welded to the right diameter without issue. But at this size, cutting and welding would be easier said than done.

Thankfully, Eclipse’s skilled and experienced spring personal were up for the challenge. With a spring cut length of only about 0.300 inches, delicate handling and precision attention to detail would be necessary. The fine motor-skills of Eclipse’s operators made short-work of the tiny spring.

In 2019, Eclipse made a key investment in a new piece of equipment designed to aid in spring operations such as this – A Laser Welder. Equipped with a built-in microscope, welding becomes the very simple operation of lining up the weld location with the scope crosshairs and pressing a foot pedal. The precision power and duration control of the laser strength allows minuscule welds to be placed with exacting accuracy. Today, Eclipse has multiple Laser Welders to keep up with production demand.

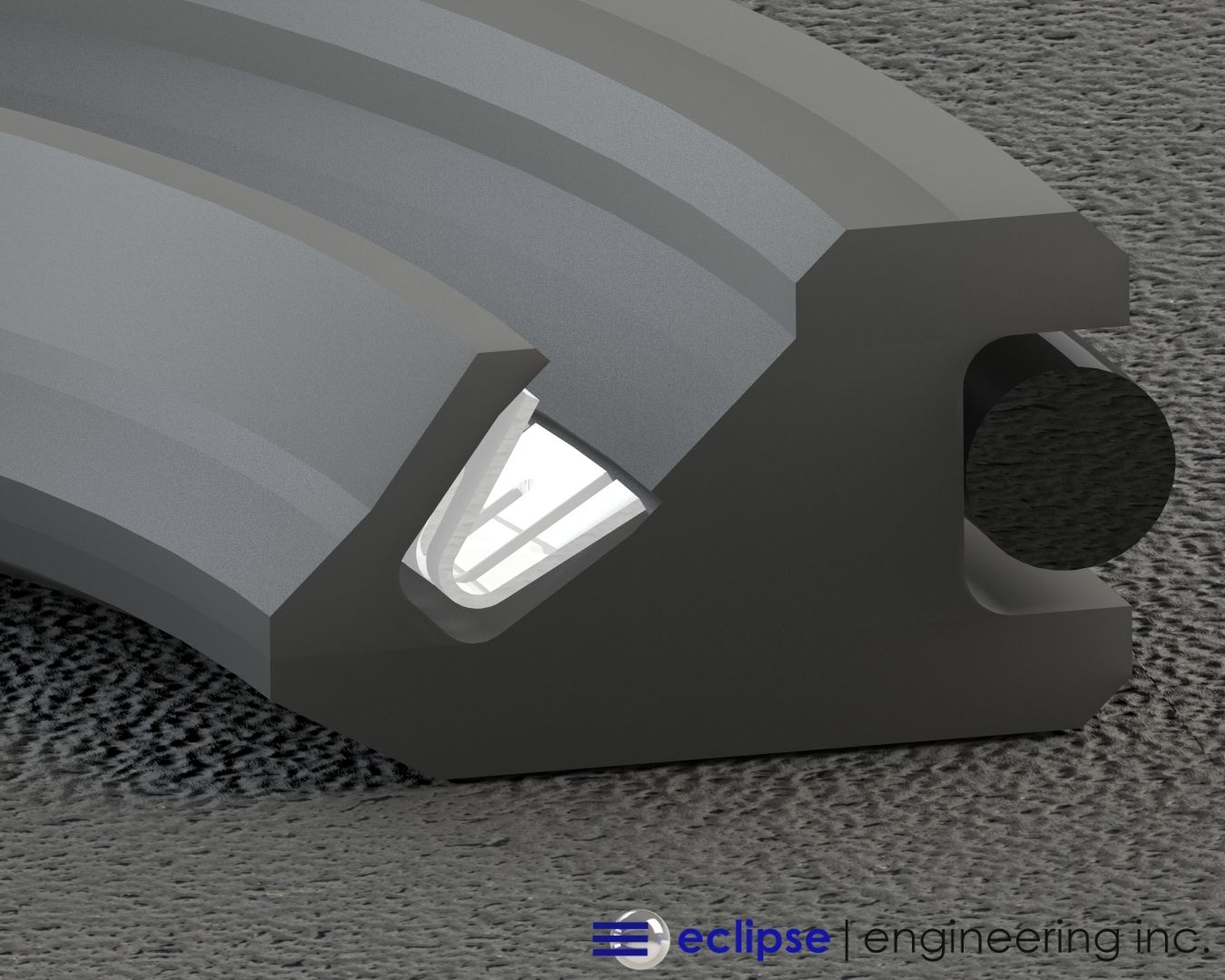

Turning to the design of the seal jacket, Eclipse was again challenged with inherent difficulties manufacturing a seal at this minute diameter. The seal inner diameter would not allow the machining of a typical seal contour, it is simply too small to fit any kind of profiling tool inside. The ID would have to be drilled straight through.

While this sounds like a straight forward procedure, this presents some major problems with the seal design. With no way to make clearance for the heel, or solid portion of the seal, shaft interference would have to be carefully controlled. Too much interference would make the shaft very difficult to install, while too little would not provide adequate media scraping and reduced service life.

But because the inner diameter needed to be drilled, the dimension would be dictated by the size of the drill bit. However, due to the nature of the seal material, the resulting hole size could either shrink or grow after cutting.

Eclipse chose its EU040: Premium Grade UHMW which would provide long wear life and very effective scraping of the viscous media. But a drilled hole in UHMW would most definitely not match the size of the drill bit.

In this case, only one or two thousandths of an inch could make the difference between a successfully functioning seal and one with severe installation problems. Eclipse’s skilled machinists with decades of combined experience proved to be invaluable as the correct size drill was chosen to allow the perfect amount of installation interference for the seal.

Without the ability to design in multiple sealing points on the jacket combined with nested V-Springs, Eclipse needed to maximize the scraping potential of the canted coil spring. This was accomplished by cutting back the inner diameter sealing lip to therefore locate the primary contact point directly below the most focused part of the spring load.

With the spring and seal jacket complete, assembling the two components would be the last step of production. Canted coil springs are typically very easy to install in seal jackets. Most of the time, larger spring series at reasonable diameters are simply installed by hand.

But a spring this small going into a relatively high durometer UHMW jacket, would not be able to be hand installed without risk of damage or incorrect orientation. Eclipse has a well-established solution to these scenarios. With the aid of a custom machined tool set, spring installation becomes a straight-forward procedure. The set includes three pieces, a cone shape for the ID and funnel shape for the OD of the seal, plus a pusher tool. The spring is fully guided and compressed into its correct orientation as it is pushed into the seal groove.

How It Performed

Sealing Epoxy and other very thick and viscous media presents unique challenges in the sealing world. Eclipse’s years of experience and development have yielded a successful formula for seal design in these situations.

Unfortunately, at the very small diameter the customer was requesting in this case, the typical design elements could not be incorporated. Eclipse found alternate ways to achieve the same goals while overcoming the innate manufacturing challenges that were posed.

Eclipse’s solution proved to effectively scrape the heavy epoxy media, successfully containing it from entering parts of the dispensing head that could cause functionality problems. The design also proved to wear resistant enough that the service intervals of the equipment did not need to be shortened.

The customer was very satisfied with the overall sealing performance and after years of successful employment in the field, Eclipse has a well-known and substantiated design standard for future products.

Contact Eclipse today for a sealing solution for your viscous media application. Whether it be one millimeter in diameter or one meter and beyond.