All About Extrusion Gaps

One of the most common questions we hear at Eclipse is: How much pressure can a particular seal handle? The answer depends on several factors, but the principal limiting factor in any seal system’s pressure capacity is the extrusion gap — often referred to as the “E-Gap.”

This critical design element determines how a seal performs in high-pressure sealing applications. The extrusion gap and the desired pressure-handling capability all directly influence seal design, seal type, and material selection. Understanding what an extrusion gap is — and how to control it — is crucial for designing high-performance seals and O-rings that withstand demanding environments.

For many industries, gaining this understanding can mean the difference between long-term reliability and costly downtime, making E-Gap management not just a technical detail but a business-critical strategy.

What is an Extrusion Gap?

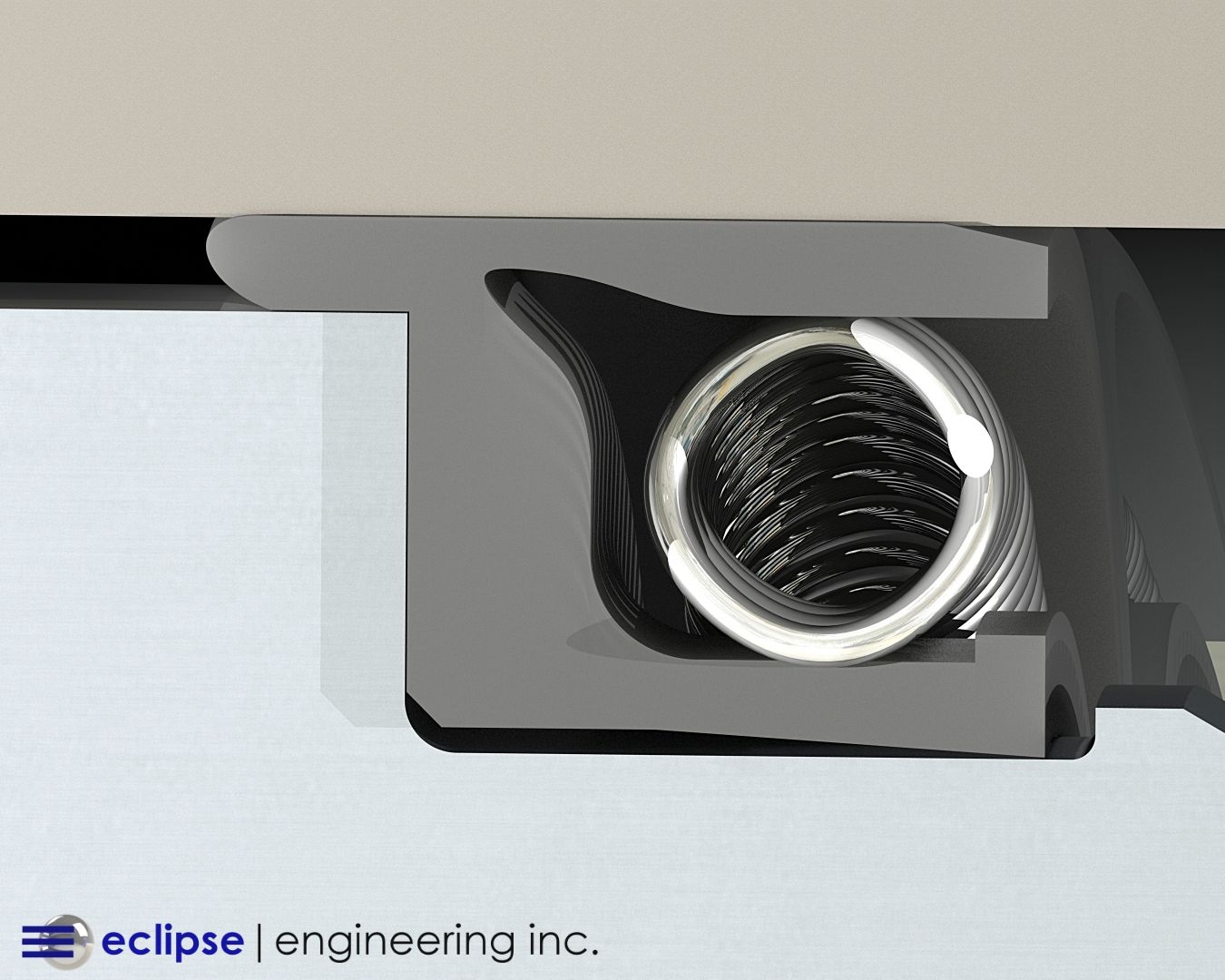

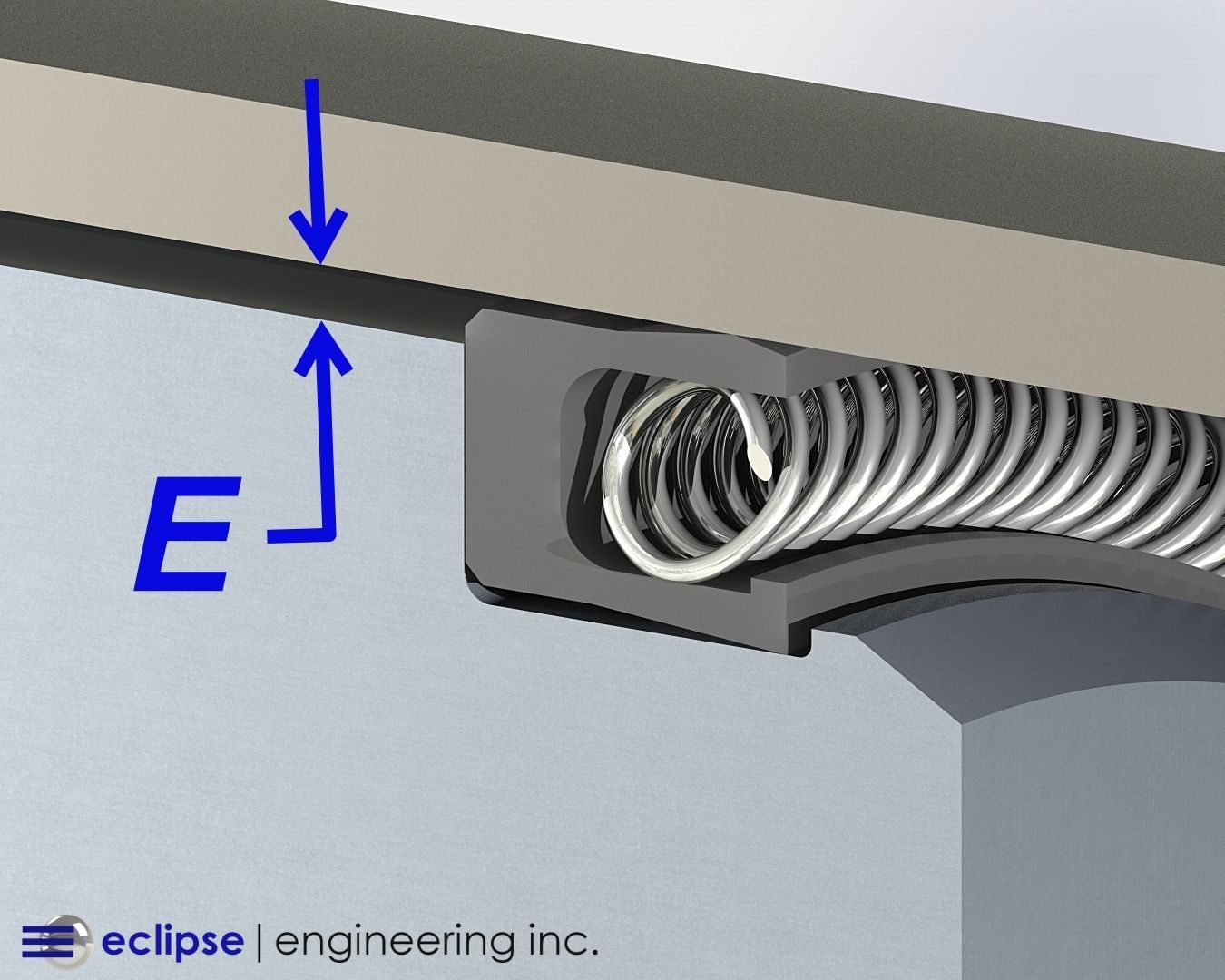

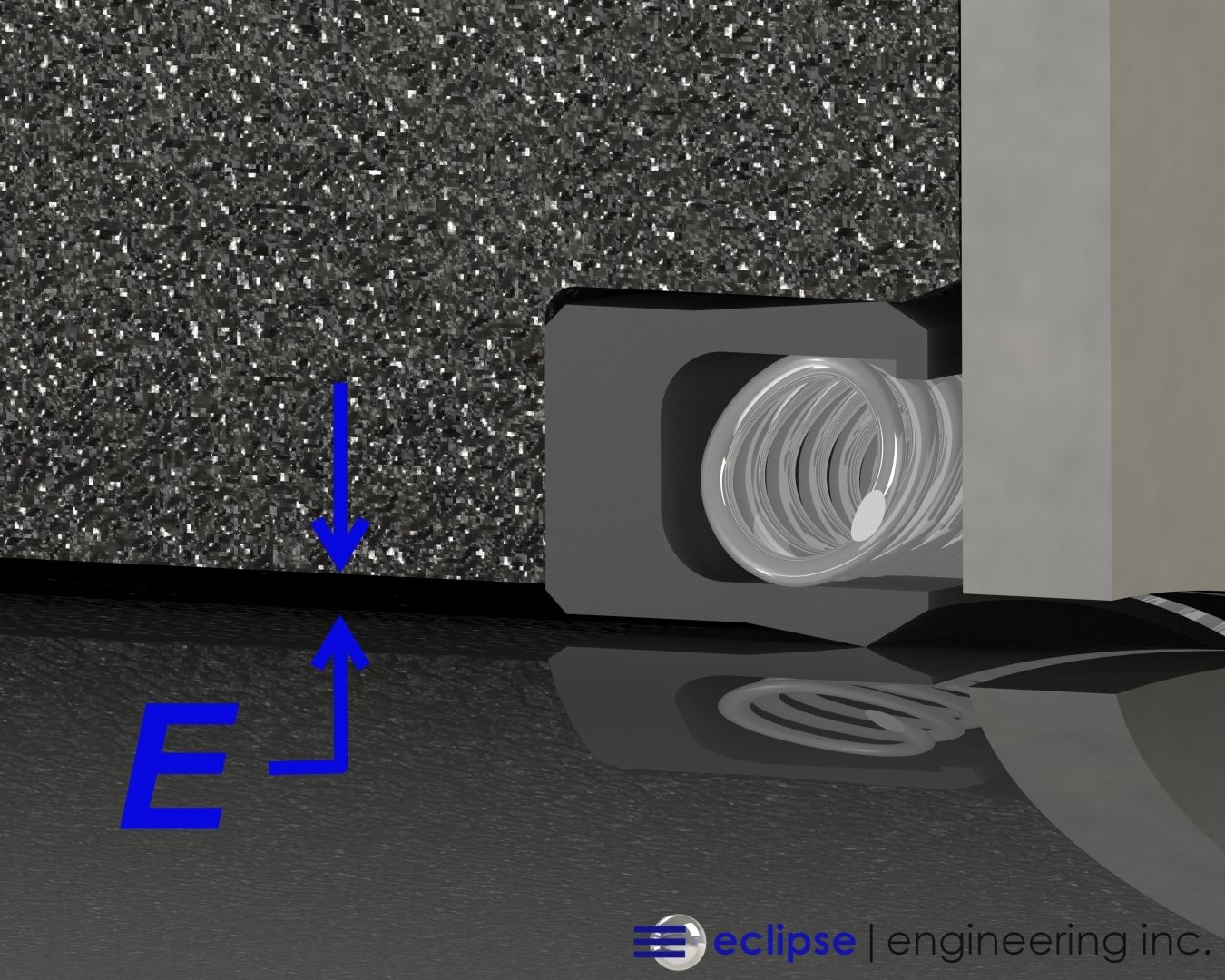

In sealing systems, the extrusion gap is the clearance between hardware components. In a piston configuration, it’s the clearance between the piston and bore; in a rod configuration, it’s the clearance between the rod and the housing it passes through.

The extrusion gap can be described in terms of radial clearance or diametral clearance. At Eclipse, we always state it in terms of radial clearance, which equals the diametral clearance divided by two. This distinction is important, as engineers sometimes misinterpret clearances, leading to an underestimation of the gap size.

While manufacturing specifications may call for precise tolerances, real-world conditions often create variation. For example, if a piston’s outside diameter is machined 0.030” smaller than the bore, the theoretical gap of 0.015” per side only exists if components are perfectly concentric.

Misalignment or side loading can increase the gap on one side while eliminating it on the other. In operation, dynamic forces, vibration, and wear can all influence actual clearance.

Because of these variables, seals must be designed for the maximum potential gap, not just the nominal print clearance. This ensures that extrusion gap seals perform reliably even in less-than-ideal conditions.

Why is it Called the “Extrusion Gap”?

The name comes from the most common failure mode in high-pressure systems: seal material extruding through the clearance gap. If the E-Gap is too large for the application’s pressure, the seal can deform, cold-flow into the gap, and eventually lose sealing integrity.

In practice, when too much extrusion occurs, the seal’s geometry changes permanently, and its ability to maintain a tight seal diminishes. This is particularly true for spring-energized seals, which have a weak point at the lip hinge where extrusion often begins. Simpler seal designs, such as seal rings, can tolerate more extrusion but may sacrifice wear life and long-term reliability.

In general, the smaller the extrusion gap, the higher the pressure the seal can safely withstand. That’s why controlling this clearance is one of the first design considerations for any high-pressure sealing application.

What Determines a Seal’s Extrusion Resistance?

A seal’s resistance to extrusion depends on several key factors:

1. Cross-Section Size

Larger cross-sections can handle higher pressures for the same extrusion gap. Conversely, for a given pressure, a seal with a smaller cross-section requires a smaller E-Gap to avoid extrusion.

2. Material Selection

Material choice is critical. Eclipse offers materials such as EH042 and EU000 that deliver exceptional extrusion resistance. If PTFE-based materials are required, blends with higher filler content generally improve performance. For example, PTFE blends like ET019 and EZ032 provide superior E-Gap tolerance.

3. Operating Temperature

Temperature has a significant effect on extrusion resistance. At elevated temperatures, materials soften, making them easier to extrude. A seal rated for a certain pressure at room temperature might only handle half that at 500°F. Conversely, at cryogenic temperatures, materials become stiffer and more resistant to cold flow.

4. Hardware Finish & Alignment

Surface finish, concentricity, and straightness of the mating components all influence the effective E-Gap in service. Poor alignment or rough surfaces can accelerate extrusion wear.

5. System Dynamics and Pressure Spikes

Seals in systems with frequent pressure spikes or pulsations may need more conservative E-Gap limits, as sudden surges can rapidly drive extrusion damage.

What If My Extrusion Gap is Larger Than Recommended?

In many designs, it’s not always possible to keep a minimal E-Gap. Larger hardware, tolerance stack-ups from bearings, and assembly constraints often require wider clearances.

For instance:

- Large Diameter Hardware: As component sizes increase, maintaining extremely tight tolerances becomes cost-prohibitive.

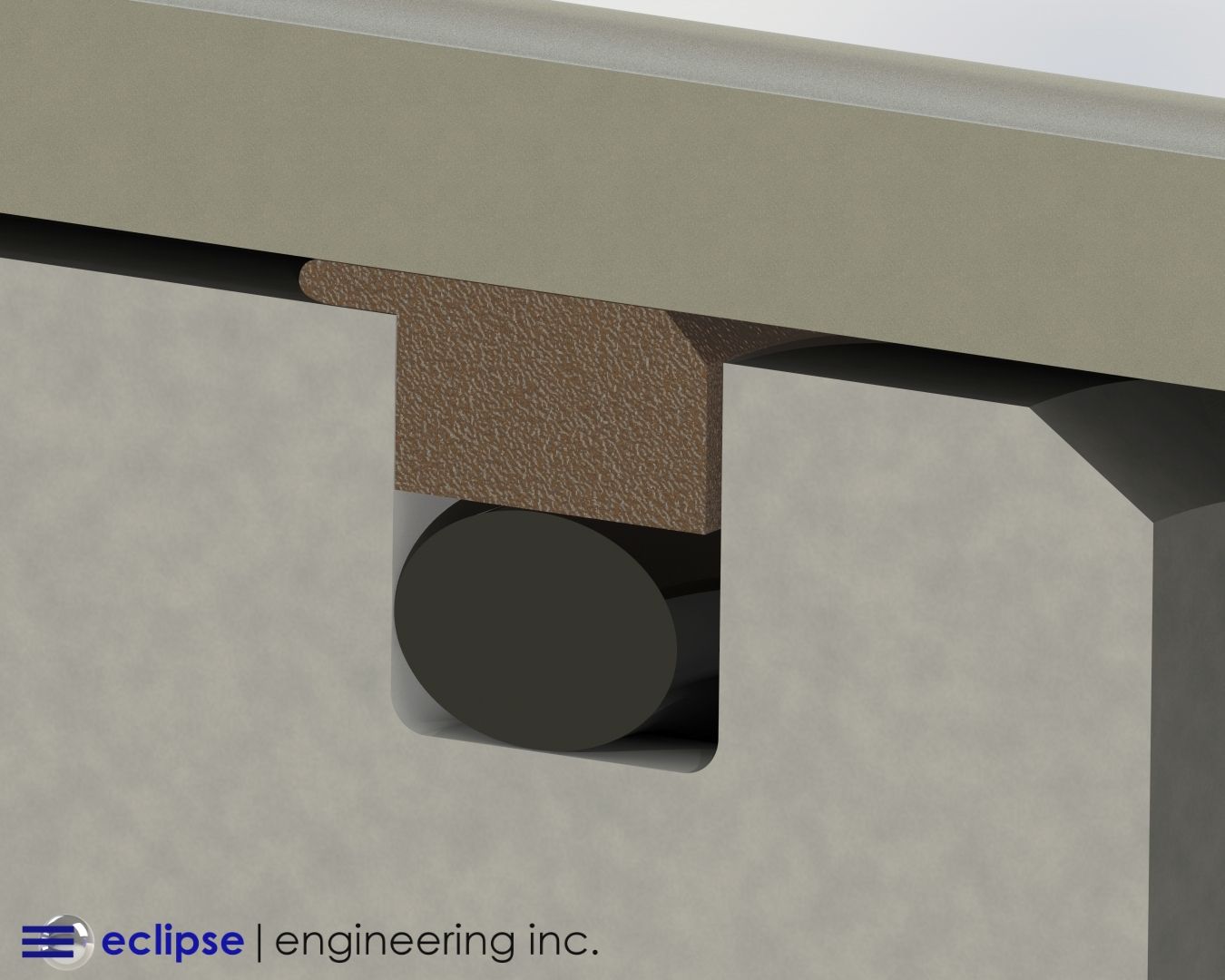

- Linear Bearings or Wear Rings: These often require larger hardware clearances to prevent metal-to-metal contact.

- Ease of Assembly: In heavy machinery, close clearances can make installation impractical.

When minimal E-Gaps aren’t feasible, Eclipse can apply several design strategies:

Extended Heel Designs

By extending the heel of a spring-energized seal, more material must extrude before the sealing surface is compromised. Eclipse’s ECSE, EVSE, and EHSE series are examples of extended heel seal solutions.

Back-Up Rings

These are high-modulus components placed adjacent to the seal to block the extrusion gap. Materials like EP033 Virgin PEEK are commonly used, offering high strength without damaging hardware surfaces. Learn more about back-up rings.

Cammed Back-Up Rings

For extreme pressures, cammed designs expand under load to close the gap completely. This approach has allowed Eclipse seals to function in systems exceeding 30,000 psi.

Dual-Seal Configurations

In some cases, using two seals in tandem — one to take the brunt of the extrusion risk and another as a primary sealing element — can be an effective solution for oversized E-Gaps.

Related Case Study

For a real-world example of how Eclipse engineers address the challenges of balancing extrusion gap requirements with other hardware constraints, read our case study: Balancing Extrusion Gap and Wear Ring Exposure in a High-Pressure CO₂ Extraction Application. This project highlights the trade-offs, custom design considerations, and performance results achieved when working within demanding operating conditions.

Measuring and Maintaining an Extrusion Gap

Accurate measurement and ongoing monitoring are essential for maximizing seal life. Precision metrology tools can confirm radial clearances during assembly. Over time, wear or deformation of hardware can enlarge the gap, making scheduled inspections critical.

Maintenance best practices include:

- Measuring clearances during every major overhaul.

- Inspecting seals for early signs of extrusion damage.

- Replacing worn hardware to restore original tolerances.

- Documenting measurements and comparing them againstmanufacturer recommendations to track gradual changes.

- Conducting finite element analysis (FEA) simulations for new designs to predict extrusion risk.

Industry Applications Where Extrusion Gap Control is Critical

Extrusion gap considerations apply to nearly all high-pressure sealing systems, but they are especially critical in:

- Oil & Gas Sealing Solutions: Downhole tools must endure extreme temperatures and pressures.

- Aerospace: Hydraulic actuators demand leak-free operation despite fluctuating loads.

- Medical Devices++: Surgical and diagnostic instruments rely on precision sealing.

- Marine & Subsea: Saltwater corrosion and deep-sea pressures present unique sealing challenges.

- Industrial Equipment: Heavy-duty presses and hydraulic systems require robust sealing against pressure spikes.

- Renewable Energy Systems: Wind turbines and hydroelectric systems often operate in remote, harsh environments where seal failure is costly.

By tailoring seals to these industry-specific challenges, manufacturers can dramatically improve service life, reduce downtime, and ensure compliance with performance standards.

Designing for Performance and Reliability

Controlling the extrusion gap is more than a design choice — it’s the foundation of seal and O-ring performance in high-pressure environments. By selecting the right materials, optimizing hardware tolerances, and incorporating advanced design features like extended heels and back-up rings, engineers can significantly extend seal reliability and service life.

At Eclipse, we specialize in custom high-performance seals for the most demanding applications. Whether your project involves aerospace, oil and gas, medical, or marine systems, our engineering team can design a solution that maximizes performance and durability.

Contact us today to discuss your unique sealing challenges and discover how we can engineer the ideal solution for your needs.