7 Best Fillers That Improve PTFE’s Performance

PTFE was discovered in the 1930s as an accidental byproduct of chlorofluorocarbon refrigerant production. It’s a synthetic compound consisting wholly of carbon and fluorine — a fluorocarbon.

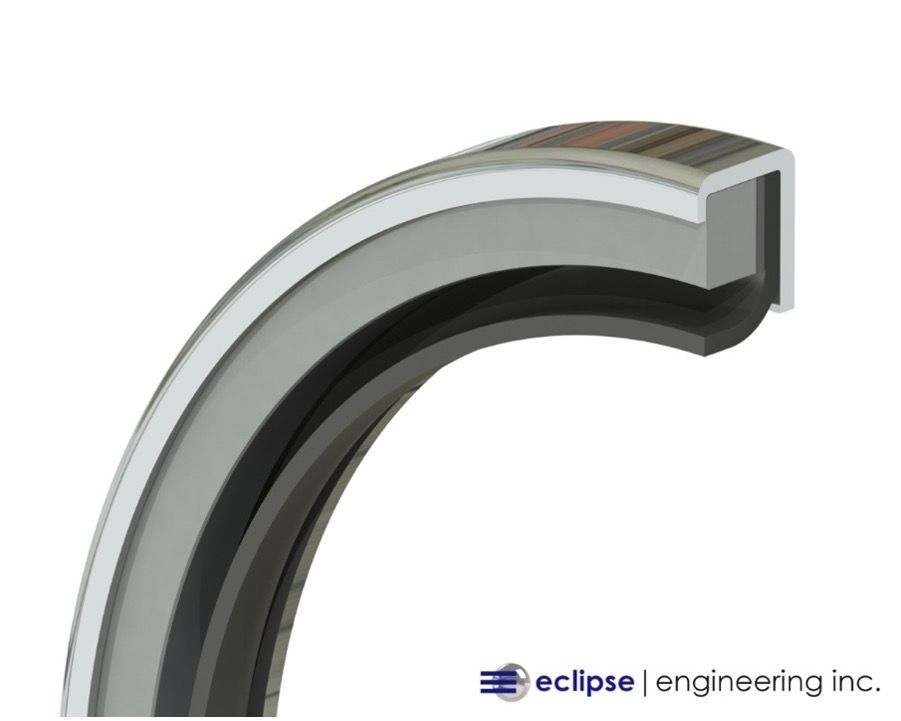

Its many unique properties make it highly attractive as a seal material. It possesses one of the lowest friction coefficients of any known material, is nearly 100% chemically inert, and can be used in temperatures from deep cryogenics to almost 600°F.

While all these characteristics are impressive, there are some aspects of Virgin PTFE that leave something to be desired. Things like wear and creep resistance could use an improvement when used in dynamic applications. Thankfully, PTFE is easily blended with other compounds to improve performance quite drastically in these areas, as well as other specific properties.

Eclipse has over 50 unique PTFE blends to choose from. Eclipse’s engineers and knowledgeable sales staff are here to guide and recommend the highest-performing seal material based on the goals of the application.

Below we’ll highlight a few of Eclipse’s favorite PTFE blends and what applications they’re best suited to.

ET002: MoS 2 filled PTFE

With the addition of a small amount of Molybdenum Disulfide (MoS 2 ), ET002 allows for better performance in friction-sensitive applications when compared to Virgin PTFE.

MoS 2 is a commonly blended solid or particulate lubricant used to make materials “self-lubricating.” ET002 is best suited for dry running applications where minimizing and maintaining predictable friction is paramount.

Industries like semiconductor production and precision robotics benefit from the extremely low and consistent friction characteristics of ET002 seals.

ET006: Carbon-filled PTFE

The addition of carbon particle filler classifies ET006 as a medium-level filled PTFE. As a particle filler, carbon homogeneously disperses in the PTFE matrix imparting wear resistance while still maintaining the majority of the virgin resin flexibility.

These properties are extremely useful when considering an upgrade from low fill material with minimal compromise in sealing efficiency. As an all-around performer in reciprocating and rotary applications, ET006 is a good starting point when specifying a seal material that offers high-value performance.

ET013: Fiberglass / MoS 2 filled PTFE

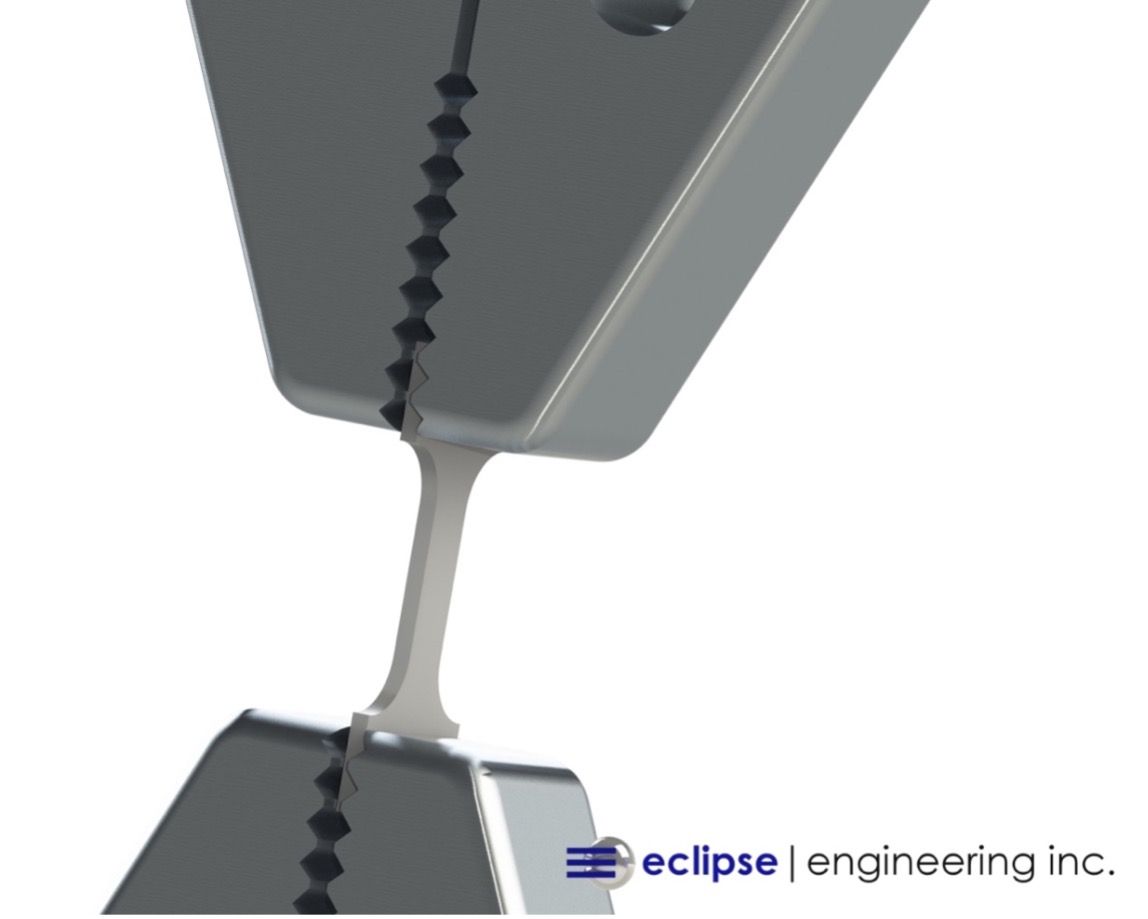

When hardened dynamic surfaces are available, ET013 offers extended wear life over lower filled compounds. Glass short fibers reinforce the PTFE matrix imparting wear resistance, extrusion resistance, and improved high-temperature performance.

ET013 is often utilized in high-speed rotary applications like engine and gear pump shaft seals. In these applications, hardened dynamic surfaces of 65 Rockwell C minimum are required.

It’s best used in lubricated service but is capable of running dry due to the additional MoS 2 solid lubricant. ET013 is used in reciprocating applications where high-pressure velocities are present and is a good choice for buffer ring seals and other pressure knock-down devices.

When used in conjunction with one of the available Eclipse spring energizers , this material makes an excellent high-temperature seal as well as an aggressive scraper up to temperatures of 575°F (302°C).

ET014: Polyimide-filled PTFE

In most basic terms, ET014 is “plastic-filled plastic.” The Polyimide filler is a high-performance polymer with excellent heat resistance and mechanical properties.

While significantly improving the wear resistance and physical properties of the PTFE, this blend still retains the non-abrasive nature of plastic. Because of this, ET014 is the first choice for dynamic sealing applications using unhardened hardware components.

ET014 is also FDA Compliant which also makes it a good option for food and medical products which often utilize stainless steel hardware with limited hardness potential.

EZ032: Carbon/Carbon Fiber-filled Modified PTFE

If wear resistance and overall toughness are the name of the game, EZ032 is one of Eclipse’s go-to materials. Proprietary blending technology is used to evenly disperse carbon and fiber fillers throughout the base resin imparting wear resistance and high-temperature capabilities.

As an example, EZ032 is being used as wear rings at 575°F (302°C) continuous operating temperature. What makes EZ032 a unique material is how the resin blending allows for a high level of fillers to be added without degrading the properties of the base resin.

Typically, higher-filled resins don’t lend themselves to being used in seals. In the case of EZ032, the desired properties of pliability and resiliency still remain — making this material useful in critical sealing applications where high-pressure velocities are present.

EZ032 is a common upgrade for rotary applications where filled PTFE materials (glass, carbon, PPS) are often specified for wear life. In those applications, EZ032 offers additional seal life with equivalent or better sealing efficiency.

Running on hardened surfaces, EZ032 makes an excellent choice for gear pump seals, mechanical face seal elements, and downhole seals.

Not to be Overlooked, ET000: Virgin PTFE and EZ030: Virgin Modified PTFE

While fillers in general greatly increase many attributes of PTFE, there are some applications where virgin or unfilled grades will perform best. These are usually static applications that will benefit from a seal with maximum compliance and elongation.

Virgin grades are almost exclusively used in static cryogenic applications where maintaining pliability at extremely cold temperatures is key for sealing performance.

Eclipse’s EZ030 is the unfilled grade of our modified PTFE. It maintains all the benefits of standard PTFE in terms of chemical compatibility, friction characteristics, and temperature range.

Its advantage over standard PTFE lies in the fact that the modified version allows better material adhesion during processing, resulting in a denser finished structure. The denser structure allows for better-machined finishes on seals as well as greater permeation resistance.

This results in a seal that’s unmatched for services in gaseous media like oxygen, hydrogen, nitrogen, and natural gas. Common applications for EZ030 are couplers, ball valves, and seats.

Elevate Your Next Project with Eclipse

Whether you’re troubleshooting a sealing application or looking for the best material for the job, Eclipse has your back.