Case Study: Sealing 15,000 PSI at 300°F With a Large Extrusion Gap

Eclipse serves dozens of industries and provides sealing solutions for applications on, off, and below the surface of the planet.

Each application has its own set of challenges whether it be manned space flight, surgical medical instruments, or high-volume automotive components.

One industry that continually presents Eclipse with challenging sealing conditions is oil and gas. In many instances, operating in the extremes of pressure, temperature, and caustic or abrasive materials are all required. Down-hole drilling processes in particular can present some of the most demanding environments or situations for seals.

Eclipse provided spring-energized seals for a customer who manufactures sensitive down-hole drilling instrumentation. The seals were working great under their initial design parameters, but that soon changed when a new worst-case, disaster scenario came up.

Follow how Eclipse addressed the problem and discovered a new solution to optimizing sealing performance, even when operating under extreme conditions.

The Client’s Issue

The seals and hardware Eclipse provided were designed around the maximum operating pressure of 500 psi. This pressure is relatively mild for a standard spring energized seal, so Eclipse biased the design around fine-tuning sealing performance.

Problems arose when the customer landed a new deep sea drilling contract and wanted to be sure the instrumentation would be protected in a worst-case situation — if every high-pressure external seal failed at the bottom of the deepest part of the ocean. The water pressure at this depth would be 15,000 psi — 30 times what the instrument seals were designed for.

To make matters more challenging, the customer wanted the seals to withstand this pressure at the highest possible temperature the instrument could see — 300°F.

Operating Conditions:

- Pressure: 15,000 psi

- Media: Seawater, Dielectric Oil, Glycol

- Stroke: 3”

- Rod Ø: 0.188”

- Temperature: 300°F MAX

The customer tested the seals at the new pressure and found they performed exceptionally well at low and ambient temperatures, despite being designed for a maximum of 3,000 psi.

The seals eventually failed at the maximum temperature due to the seal softening and allowing extensive extrusion .

The Challenge

Eclipse has utilized successful sealing solutions at pressures above 30,000 psi, but these configurations are heavily dependent on identifying hardware specifications, namely the extrusion gap (the space or clearance between the hardware surfaces that need to be sealed).

Extreme pressures can start deforming the seal and pushing it through the gap, in other words, extruding the seal. Once the seal is deformed enough, the structural integrity of the seal will be compromised and leakage will occur.

Elevated temperatures can further impact the durability of the seal. As temperatures increase the heat will inevitably soften the seal material making it easier to extrude.

The customer’s hardware was designed around the initial 500 psi and ambient temperature requirements. This unfortunately meant the specified extrusion gap was far larger than what would be needed for 15,000 psi and 300°F.

Eclipse is no stranger to high-pressure applications and has many options to bolster seal design. Increasing lip thickness and extending the seal heel length are common high-pressure handling modifications. But these designs all require additional physical space for the seal to occupy.

The hurdle to overcome was presented when it became evident that the customer’s hardware was already in production. No changes to the hardware could be made.

Eclipse decided we’d have to design a seal to handle the 30X pressure increase within the confines of the original envelope.

The Eclipse Solution

Eclipse knew it would need to get creative to handle the pressure without physically increasing the size of the seal. The first step would be to switch the jacket material to a blend with a higher filler content.

The original seals were ET014: Polyimide filled PTFE . Eclipse stepped up to ET025, which is also Polyimide filled PTFE, but at a much higher fill percentage.

The additional Polyimide significantly increases the extrusion resistance but still maintains the desirable sealability characteristics the customer was expecting. But a simple material change alone would not be enough to meet the pressure handling requirements.

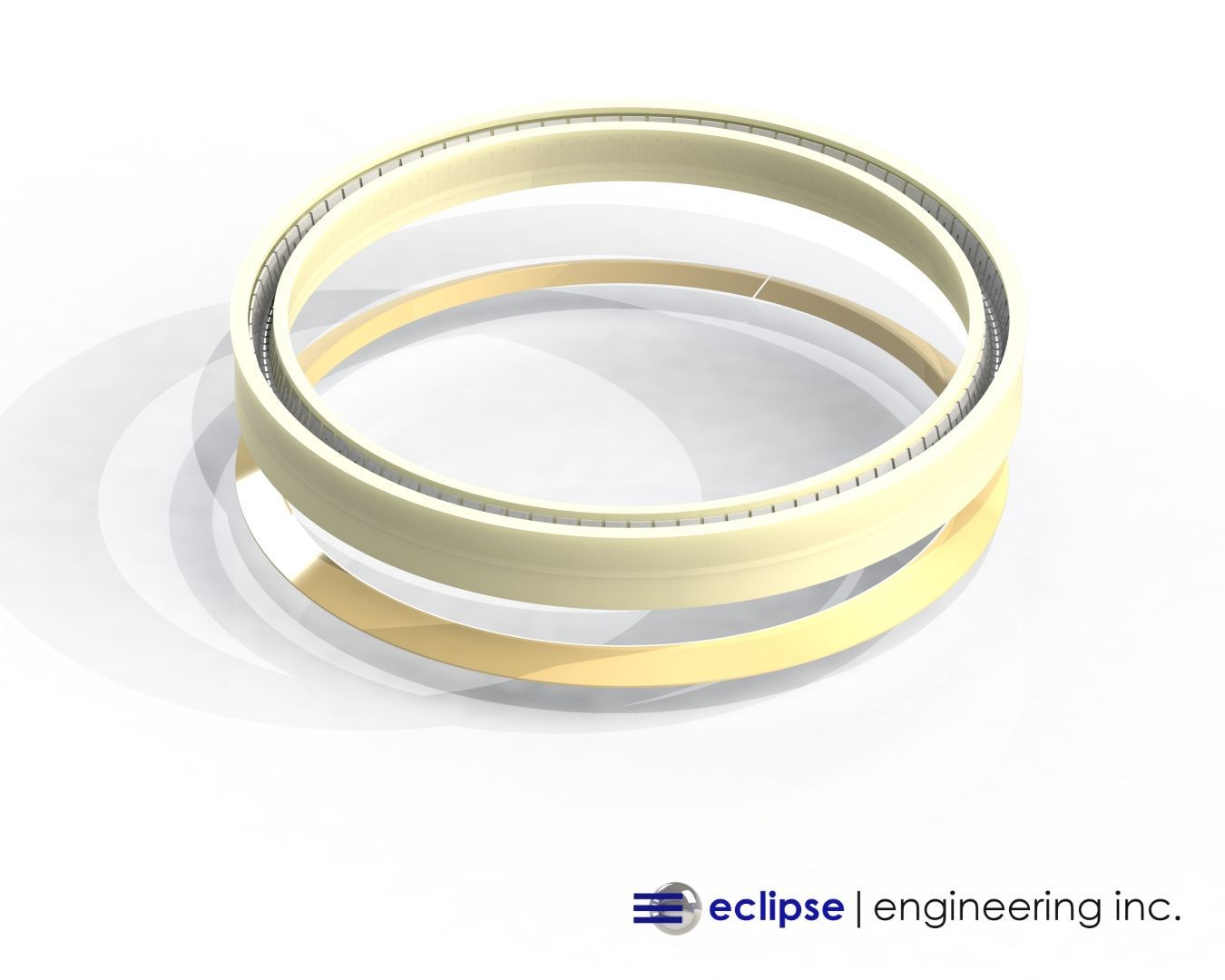

Eclipse simplified the seal geometry to allow for thicker lips on the jacket and make room for a small wedge-style back-up ring. Back-up rings are often critical accompaniments to seals when pressures get extreme. They effectively decrease the size of extrusion gaps.

The Impact of the Back-Up Ring

By adding the back-up ring to the rear corner of the seal, the gland width wouldn’t have to be expanded, which is usually the case with these types of rings.

Eclipse chose its EP033: Virgin PEEK for the back-up ring material. PEEK is a much higher modulus or stiffer material than PTFE. Consequently, it is much more difficult to extrude.

While PEEK has a high upper-temperature limit, it also retains the non-galling and flexibility attributes of plastic. There’s no risk of damaging the hardware, unline a metallic back-up ring.

The wedge shape of the back-up ring also contributes to the increased pressure handling of the seal. The wedge is angled so that as pressure forces the seal to the back of the gland, the heel rides up on the back-up ring keeping it away from the extrusion gap.

How it Performed

With higher filled jacket material and the back-up ring effectively minimizing the extrusion gap, the seals passed the 15,000 psi at 300°F worse-case sealing test.

The customer could now safely market their instrumentation as prepared to handle any drilling situation in any location.

This was all done without any changes to the hardware, saving the customer from an extremely costly redesign and rework. It’s also important to note, Eclipse achieved the higher-pressure rating without compromising the sealing performance at the lower operating temperatures.

Whether your next instrumentation requires seals that can withstand extreme pressures or elevated temperatures (or a combination of both), Eclipse can help find a solution that will exceed your expectations.