Should You Use a Cantilever V-Spring? Here Are the Pros and Cons

Shortly after the discovery and use of PTFE as a seal material, the need for a secondary energizing method became apparent.

Unlike rubber or urethane which possess elastic and spring-like properties, PTFE will not return to its original state once deformed.

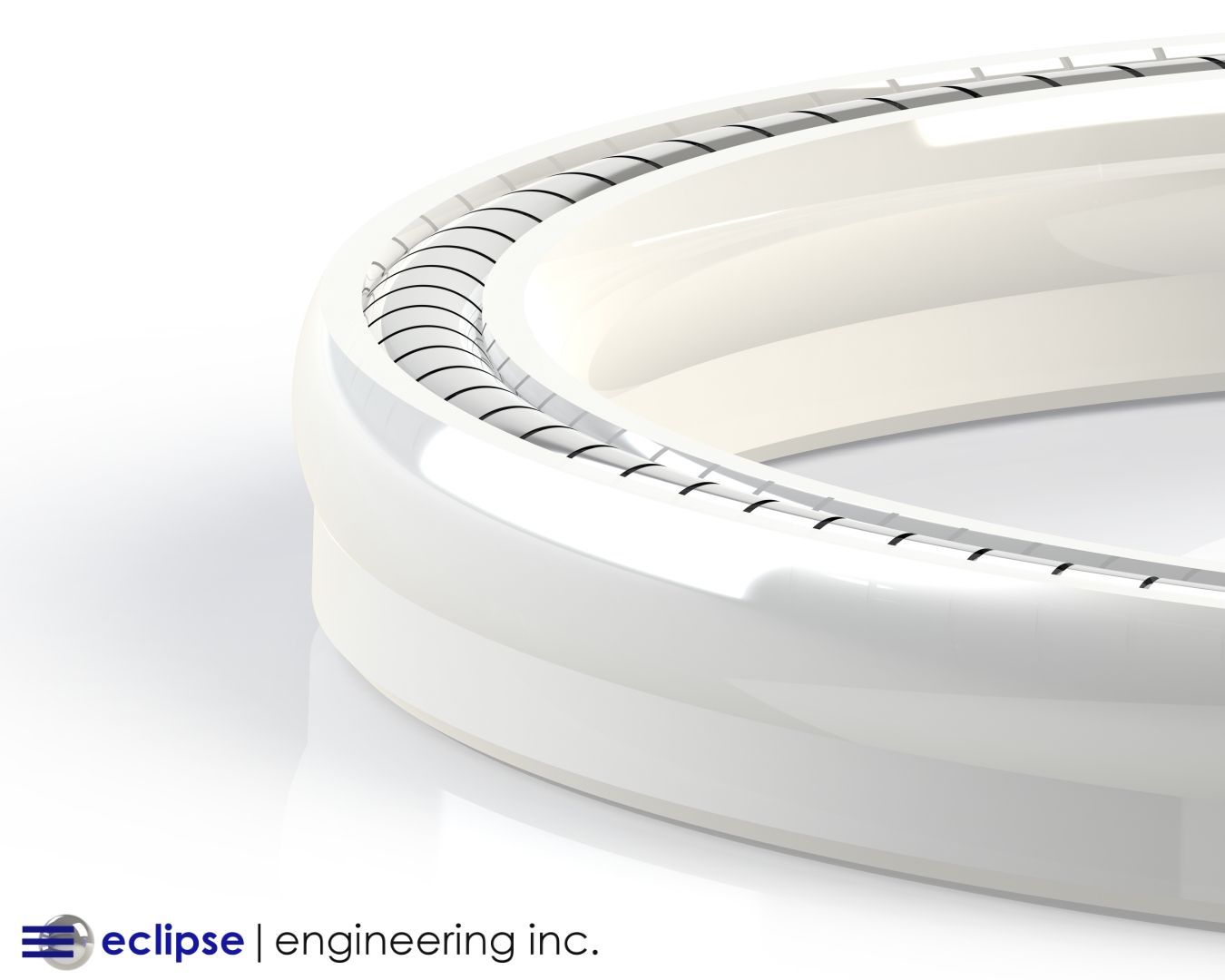

This is obviously not a desirable trait for sealing material, especially in dynamic sealing applications. PTFE seal designs were soon developed to incorporate energizing elements such as O-Rings and metallic springs. These energizers ensure the PTFE seal is always in contact with the sealing surface.

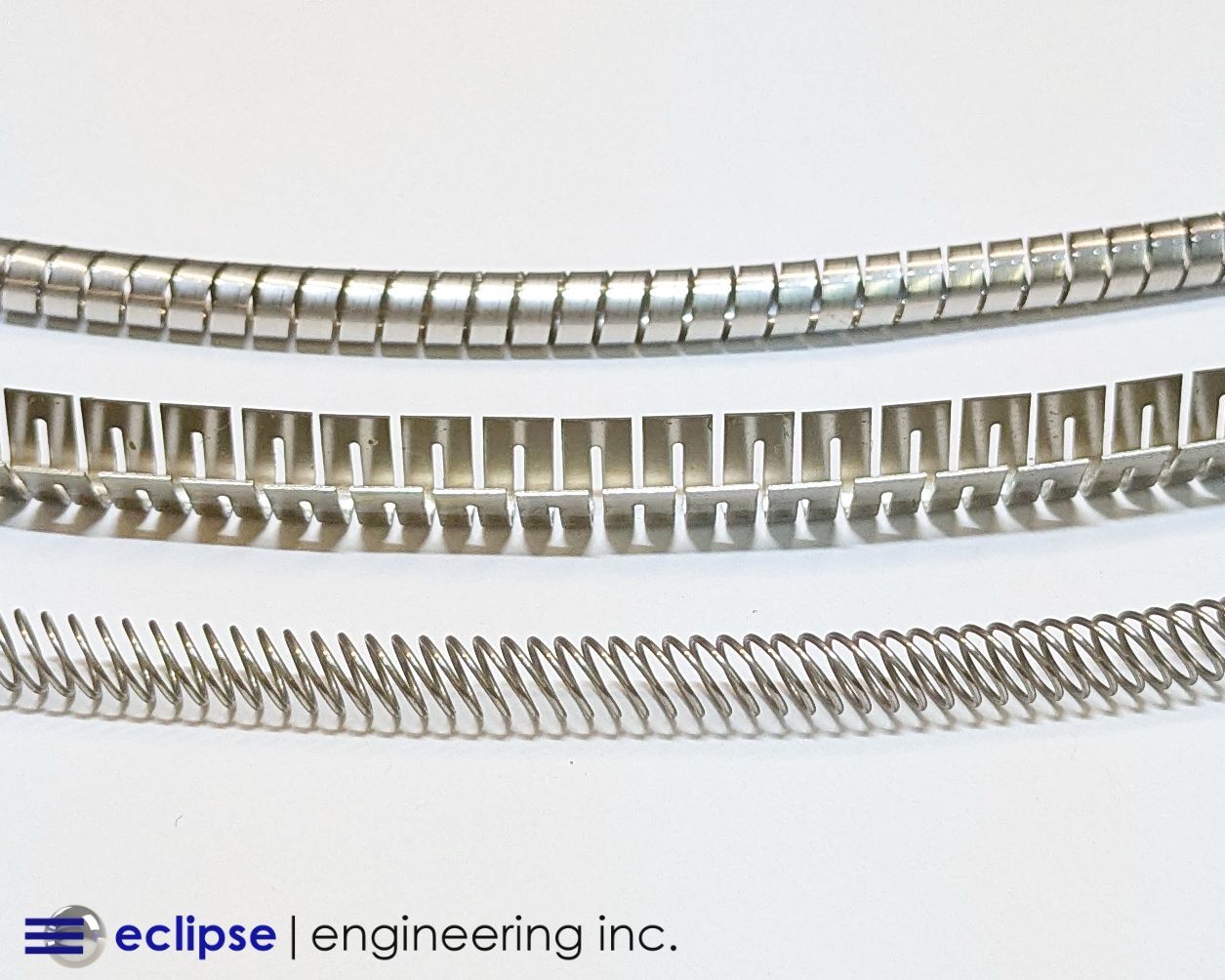

Eclipse utilizes three different spring types to internally energize PTFE and other polymer seals, each with its own advantages and drawbacks. Below we’ll discuss in detail some of the pros and cons of Cantilever V-Spring and some of the applications it’s best suited for.

The Advantages of V-Spring

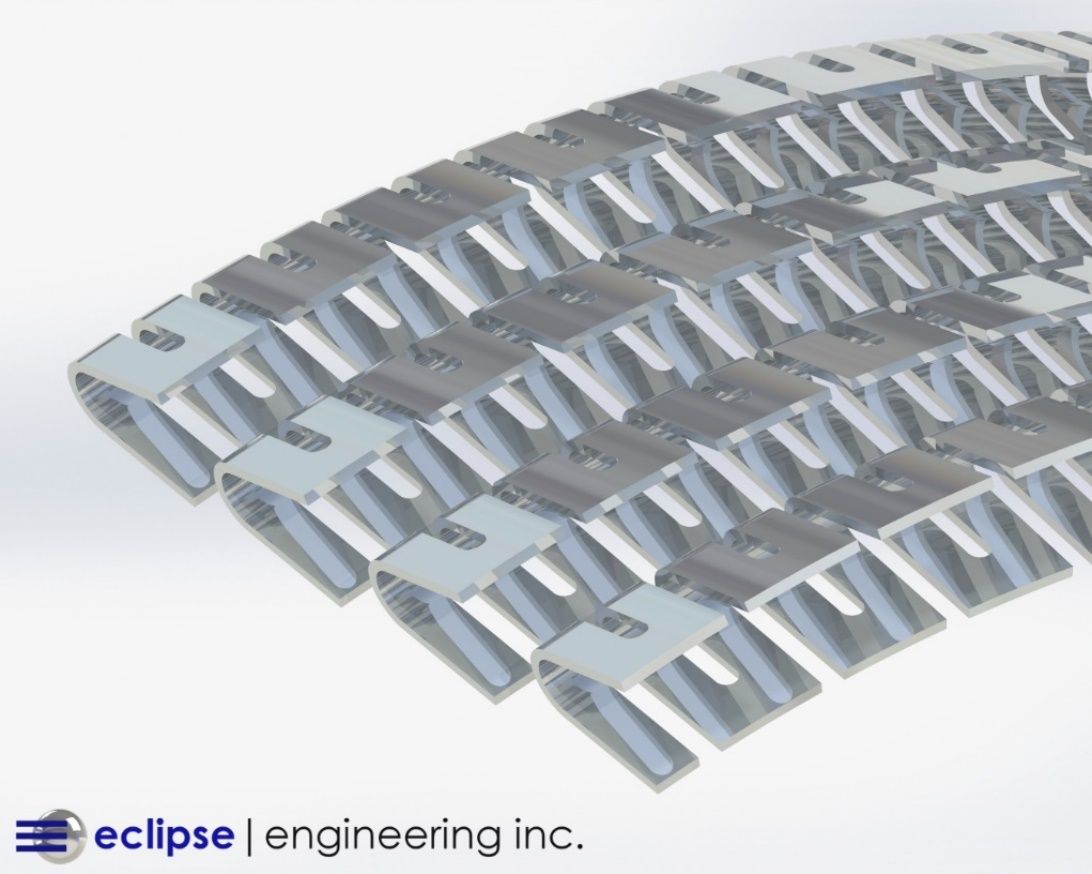

V-Spring consists of thin strips of sheet metal, most often 301 stainless steel, that is formed into a V shape. Relief cuts are put into alternating sides of the V to allow the spring to be formed into a circle. The shape acts as a sort of cantilever leaf spring inside of the seal jacket, hence the name Cantilever V-Spring.

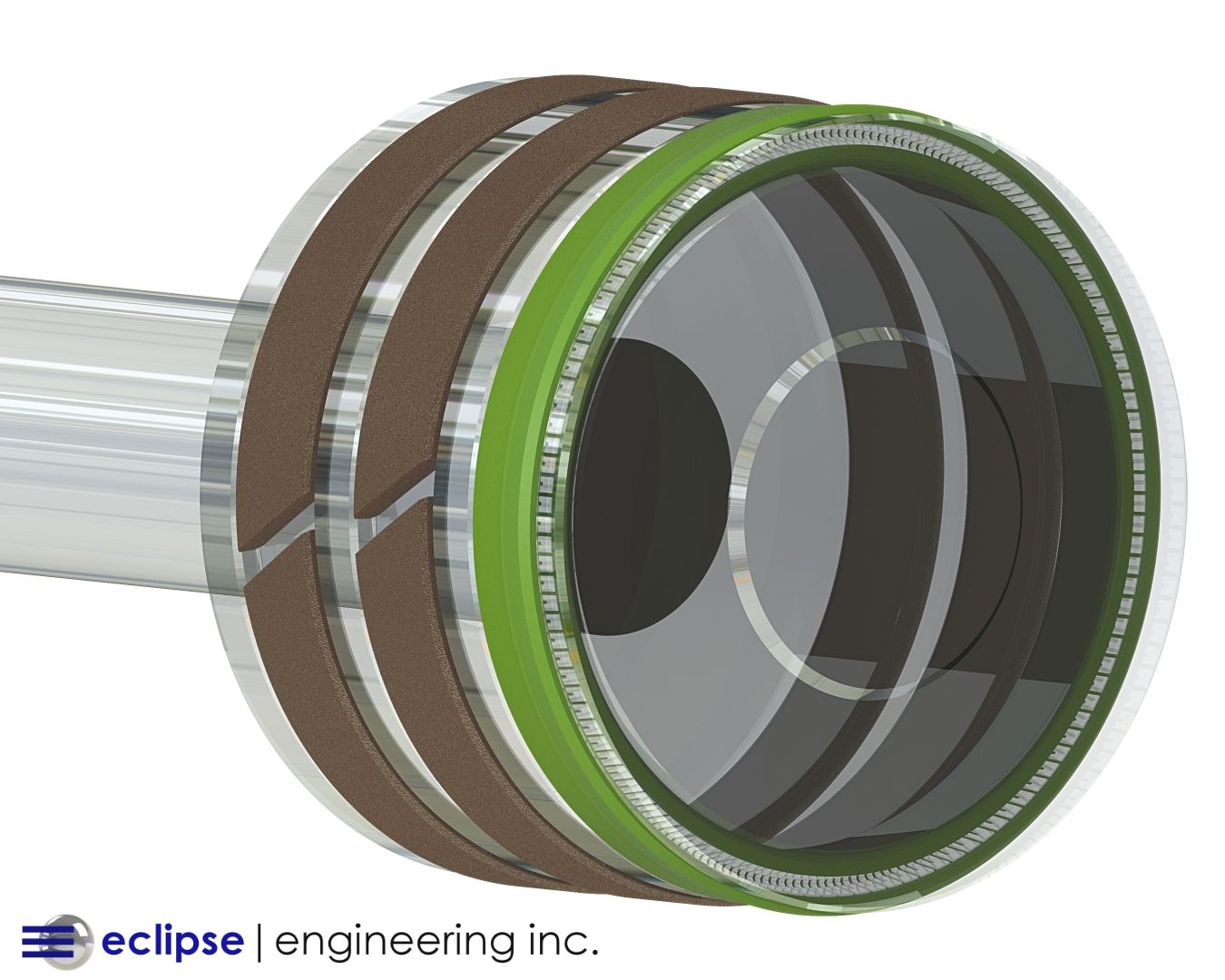

Energy and load are focused at the ends of the V-spring. This coincides with the seal jacket geometry to create a concentrated point-load at the leading edge of the seal. This configuration is ideal for reciprocating applications that need to not only seal but scrape away or exclude media.

They’re Effective With Many Media

V-Spring combined with a highly wear-resistant seal material like UHMW-PE can create an extremely effective sealing solution for thick and viscous media like adhesives and epoxy resins.

To further amplify the scraping and sealing potential, V-Springs can be stacked or nested within the seal jacket. This will multiply the spring load and allow the use of multiple, redundant sealing contact points on the jacket.

They Have a Wide Deflection Range

V-Spring has the widest deflection range out of all the available spring types. It is well suited for very large diameter components where hardware misalignment, dimensional tolerances, and clearances are substantial. The increased deflection range ensures the seal is always in contact, even in fluctuating gland conditions.

They Can Withstand High Temperatures

The shape of the V-Spring also makes it well suited for very high-temperature applications. A PTFE seal jacket at 450°F or higher can soften enough that a spring-like Canted Coil can actually start embedding into the seal lips.

V-Spring’s comparatively large, flat footprint resists embedding in the jacket much better. Therefore, V-Spring is the spring of choice for high-temperature requirements.

They Can Be Filled With Silicone

Another unique attribute of V-Spring is its ability to be Silicone-filled. This is often employed in FDA and food processing applications that use Clean-In-Place procedures.

The Silicone fills the entire spring cavity encapsulating the spring but still allows it to provide energy to the seal jacket. This keeps media from packing into the spring cavity and around the spring, which can be very hard to clean out.

They’re Cost-Effective

While V-Spring has many performance advantages in the right application, many times it is chosen based on cost alone, especially when high volumes are needed.

V-Spring is manufactured by forming strips of sheet metal through progressive dies and punches. It’s the most economical spring to produce in quantity and is often sold in spools hundreds of feet long.

It’s also the most economical spring to cut to the right length for the seal diameter and weld in a circle. V-Spring can be welded, like most sheet metal, with a simple resistance welder.

They’re Fast to Make

Run rates are optimized with this much faster technique, especially compared to Canted Coil springs which are our Eclipse laser welds. While it’s possible to install V-Spring into the jacket without welding, Eclipse fully welds every spring it produces to make certain that the load is consistent around all points of the seals.

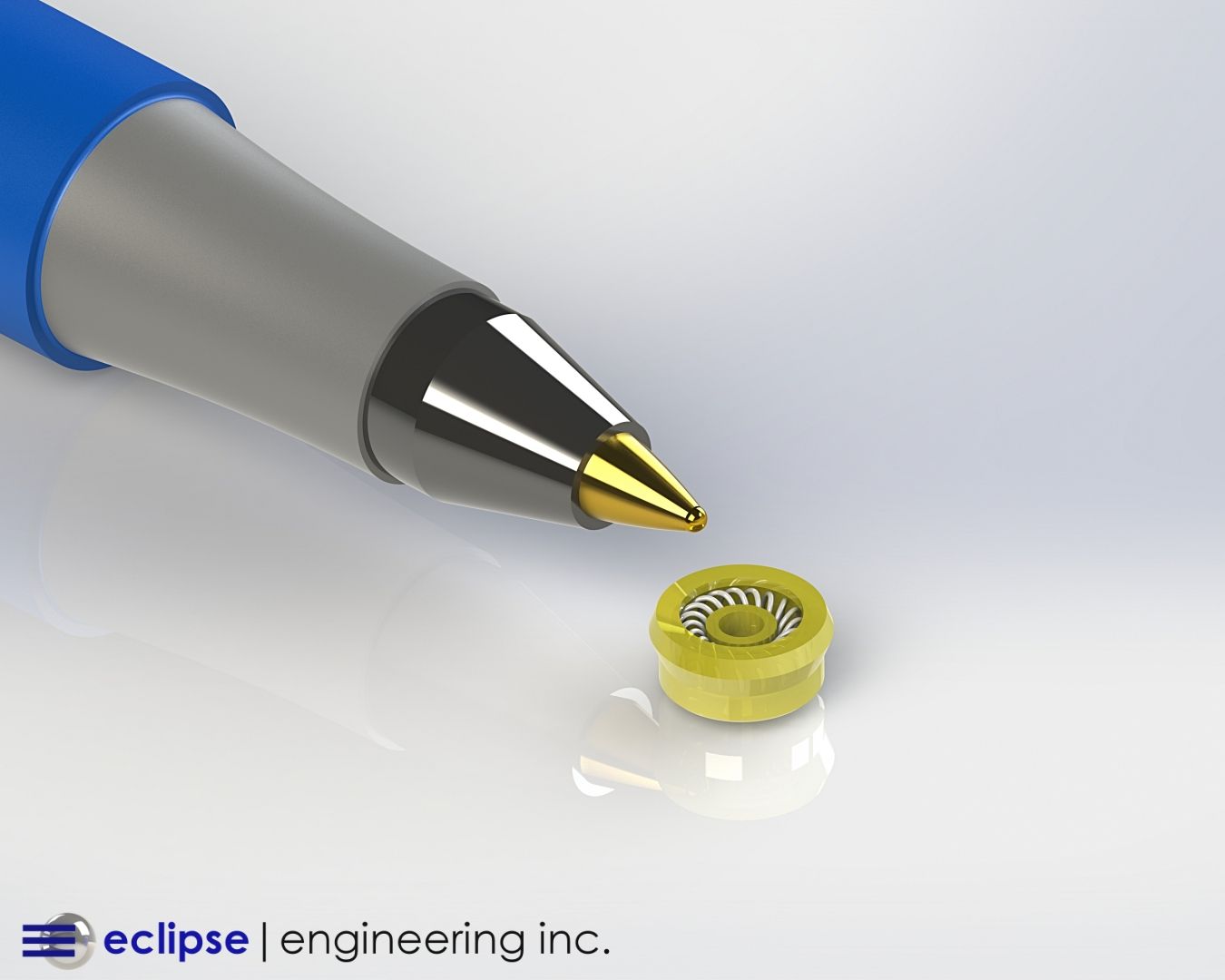

In volumes of tens of thousands of pieces, where some tooling costs can be amortized and diameters are relatively small, a circular spring pattern can be etched into sheet metal and then formed into the V.

This eliminates the cutting and welding steps altogether providing the lowest cost spring energized seal possible.

The Disadvantages of V-Spring

While the focused, point-loading of V-Spring was listed as an advantage earlier, this very same aspect can be a drawback in some applications.

V-Spring is rarely used in rotary applications where the relatively high point-loading would needlessly accelerate the wear of both the seal and the hardware.

They Gradually Decrease Spring Load

V-Spring possesses a very linear load curve, meaning load increases proportionally with the amount of compression of the spring. This means that as the seal wears, the spring load gradually decreases. Therefore, the seal might be overloaded initially and underloaded near the end of its wear life.

This is in contrast to the Canted Coil spring which has a very flat load curve. Spring force stays almost constant over its deflection range. This makes it a much better choice for high-speed and torque-sensitive rotary applications as the load will vary a little over the life of the seal.

Wear life can also be optimized with the predictable, controllable, and constant spring force.

They Can Yield

Another disadvantage to V-Spring is its potential to be yielded. If the spring is over-compressed or distorted in some way, it will no longer function.

This can be a problem if a sealing system has a possible high back-pressure scenario. Eclipse has seen V-Spring over-compressed and fully flatten in a down-hole drilling application that saw an unexpected back-pressure event.

Canted Coil, on the other hand, can be fully compressed without damage and is much more difficult to yield in any direction. This makes it the better choice for seals that need to be installed in hard-to-reach glands where the seal needs to be contorted and/or maneuvered in multiple ways.

They Have Diameter Limitations

V-Spring also has some lower diameter limitations unlike Canted Coil or Helical spring.

At smaller diameters, the inner “tabs” of the V-Spring will start to overlap and will crowd around the inside diameter. This limits the small diameter potential of some series of V-Spring.

Eclipse is Here to Help

V-spring is widely used throughout the sealing industry and has many advantages.

It might be the best choice for your sealing application or there might be a better option.

Either way, Eclipse is here to utilize its years of experience and engineering expertise to specify the right spring energized seal to meet your sealing goals.