The Best Spring Energized Seal Lip Styles For Every Project

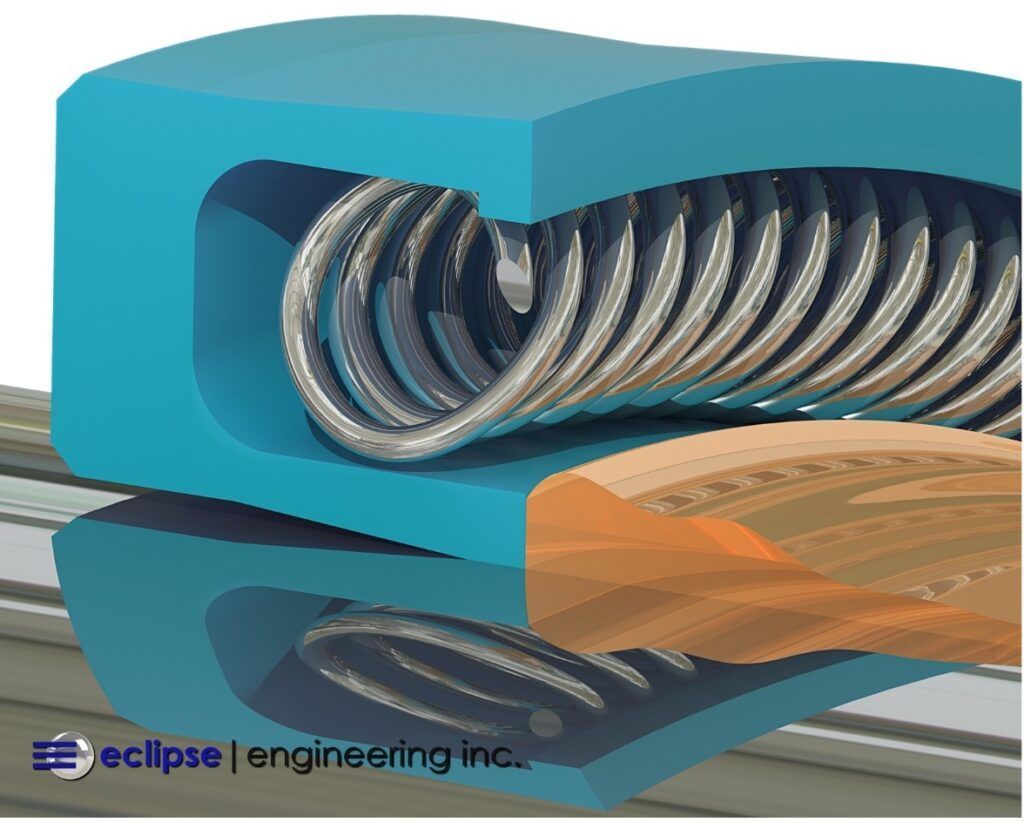

Spring Energized Seals can be found in all kinds of applications across the spectrum of industries and sectors. While the pros and cons of the different spring types contained in the seal are often discussed, the style of sealing lips can also have a significant impact on performance.

Every spring type has at least 4 standard lip style options, so choosing the right style for your application is critical. There are a number of design factors that need to be taken into account to ensure the best option is chosen for the application.

Hardware configuration, seal installation direction, media type, and dynamic motion all need to be taken into consideration to correctly specify a lip type.

Eclipse’s team of experienced engineers is here to recommend the best design, whether standard or custom. Below we’ll discuss the basics of the common lip styles and where they’re used.

Standard Chamfered Lip Design

In Eclipse’s spring energized seal catalogs , the standard lip design is referred to as the LW style. It consists of chamfered lips on both the OD and ID of the seal. This lip style is suited for most general-purpose applications.

The chamfers make for easy seal installation and reduce the risk of damage in gland configurations where the seal must be installed face (spring side) first.

This can also be particularly important in blind installation situations. For example, when a rod seal is positioned in a groove that is located deep inside an assembly, there will be no way to externally guide the shaft installation through the seal.

But more than just lead-in chamfers for installation, the sealing point is carefully positioned to allow broad energizing from the spring. This extends wear life and helps promote consistent sealing performance throughout its service life.

Scraper Lips

The scraper lip design puts a sharp point on the leading edge of the sealing lip. It can be on either the ID or OD lip of the seal, or both lips depending on whether it’s a rod or piston seal application and the gland configuration.

The scraper lip puts a focused point contact between the seal and media allowing for wiping or excluding action. Scraper lips are often found where a seal is being used as an environmental barrier keeping outside debris or contamination from entering a system.

Scraper lips are also often employed in reciprocating applications sealing viscous media. A chamfered lip can potentially allow media to build up underneath the lip and cause a hydroplaning effect, allowing leakage. The scraper lip helps prevent this.

With a canted coil spring, the scraper lip can be “cut back” on the dynamic side of the seal. This shortens the lever arm of the lip and further concentrates the spring force. These designs are used when maximum scraping action is required.

The scraper lip is also used for seal retention in stepped glands. The sharp point locks in behind the barb of the stepped gland ensuring the seal is securely held in place. Often a step height of 0.020” or less is all that’s needed to properly retain the seal.

Radiused Lips

Sometimes called bubble or beaded lips, lips with a full radius are well suited for specific applications. The radius allows for a large contact area with the mating hardware. This extended surface contact creates a longer path for any leakage to penetrate thus providing excellent seal-ability in gas media.

The geometry also allows Eclipse to use special tooling and machining techniques when turning the seal jacket to provide a super finish on the surface.

When applied to Eclipse’s EZ030: Virgin Modified PTFE , the resulting finish can provide enhanced gas sealing performance and is often employed in cryogenics and other critical sealing applications.

Radiused lips can also be beneficial if the seal needs to pass over any ports or other irregularities in the hardware. The lack of any sharp edges and gradual radii will permit smooth transitions over hardware features. This minimizes the possibility of unnecessary seal damage.

Get a Custom Lip Configuration at Eclipse

Eclipse is by no means limited to the standard lip styles listed in our Spring Energized Seal catalogs. Our team of engineers is here to specially tailor the best sealing solution possible for your specific application.

While the lip styles we discussed serve well in many sealing systems, simple lip geometry changes can potentially yield large performance gains in areas such as leakage control and wear life.

Using a radiused lip in a scraping application will probably not work out well. Using a standard chamfered lip design to seal Hydrogen will likely be less than optimal.

If you’re utilizing a standard lip configuration and it’s leaving much to be desired, Eclipse is here to help.