How Seals in Modern Farm Equipment Increase Uptime

Before mechanization on the farm, different tools and implements had fairly simple designs. Seals were only found in the sucker pump tied to the Aermotor windmill, where there was a leather seal in the transmission and the pump had leather packing.

The History of Farming Technology & Seals

The farm tractor evolved to include rubber lip seals and some O-rings to help keep fluids in and the dust out. While sealing was important in the early 1900s, it didn’t become highly significant until hydraulics were added to farm implements, creating the ability to move product from the fields and into silos and finally to market.

The family farm stayed small for many reasons. The first was the expense of equipment that could improve productivity. Unknown crop yield and market uncertainty often slowed the growth, so farmers often just grew enough to satisfy the needs of their family and to cover expenses, with maybe a little left over.

When farming became more commercialized, farming equipment no doubt saw a huge leap in design technology, with new investments to advance the science of farming.

The Evolution of Farming Technology

Today’s modern farming equipment utilizes high-pressure hydraulics with piston pumps and motors to improve efficiency. You can find hydrostatic drive motors for running equipment, hydraulic cylinders for virtually every operation to enable the large equipment to work the fields.

Modern crop growing has also seen great improvements to allow for higher yields in the field. Rather than sending a tractor or aircraft to the field to spray crops for insects or weed control, modern farms utilize drones to accurately place just the exact amount of product down for the conditions under the craft.

Seals in Modern Farm Equipment: Increasing Uptime

Technological advancements have created an explosion of technical seal products in today’s modern farming equipment.

A major driver has been improving the uptime of equipment to ensure that the labor to operate the equipment is kept to a minimum. These efficient industrial farms will move equipment between farms to increase uptime and utilization, resulting in a quicker pay back.

This increase in productivity can’t happen unless the seals in the equipment is specified for long life, with any parts replacement happening at night when the equipment isn’t in use.

Today’s farm equipment has reached the level of modern construction and mining equipment, where uptime is the highest priority.

Shaft Seals in Gang Mowers

A few examples of where sealing technology have been shown to save on downtime are gang mowers. These pieces of equipment are generally run with hydraulic motors.

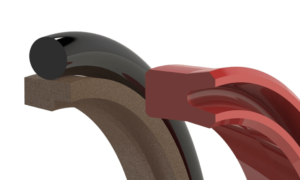

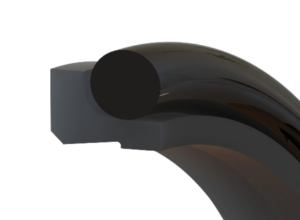

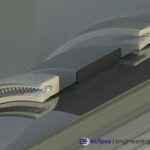

The shaft seals in gang mowers must withstand return pressures up to 150 psi, without damaging the seal. This is accomplished with specially-blended Teflon lips sandwiched in a can for anti-rotation.

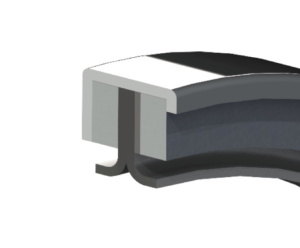

Hydraulic cylinders using a combination of buffer rings and Urethane u-cups to keep oil in, and piston seals from filled Teflon to help improve life and keep heat down to a minimum during operation.

The bronze bushing found everywhere in the old farming equipment have been replaced with composite bushings. Composite bushings retain lubrication and run well in wet conditions, such as cotton or rice farming, as well as in dry, heavy dust environments. Composites minimally wear shafts and can carry much greater loads than their bronze counterparts.

Seals Around the Tractor Cab

Environmental seals around the tractor cab make the cab more of an office than a tractor. Auto pilots and auto throttles plant at exactly the right rate with no waste, while keeping the operator in an environmentally clean “cab like” compartment, which helps increases the productivity of the operator.

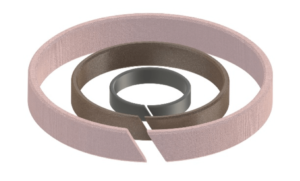

Rubber-energized and spring-energized dynamic seals allow this equipment to operate at much cooler temperatures, which in turn increases their uptime in the environment. With cooler running hydraulics, the equipment doesn’t need the energy to help cool the hydraulics.

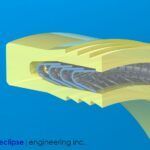

Rod Wipers & Scrapers

One added element that extends the life is the rod wiper or scraper. The field (by virtue of the application) is extremely dusty, and having active wipers allows for these high-pressure systems to operate in clean fluids, which improves life and time between replacements.

Wipers can be designed to be replaced with or without disassembly of the cylinder, allowing this element to be replaced without taking the unit out of service for an extended amount of time.

Industrial farm tractors are being asked to accommodate a wide variety of attachments. While Power Take Offs “PTOs” have been around for decades, these power systems are now being tasked with accommodate a wider variety of attachments, which places greater loads on the mechanical outputs of these devices. Not to mention the accommodation of transmissions which run at very low and very high speed.

Higher shaft speeds are accomplished with the use of Teflon lip seals to retain lubrication and handle various transmission fluid types. The Teflon lip seal, while found in many rotary applications, provides low-friction and dirt exclusion, while keeping fluids in and dirt out.

Eclipse Engineering has a range of standard products and can custom design for your unique applications that require seals not yet invented to fit your specific needs. Learn more about Eclipse’s capabilities in the energy industry »

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!