Spring Types and Materials in Sealing Systems

Springs are an integral part of all sealing systems. A simple air cylinder has O-rings to seal in the air, and the O-ring exhibits spring-like qualities to ensure a good seal over a broad temperature range.

Metal Springs

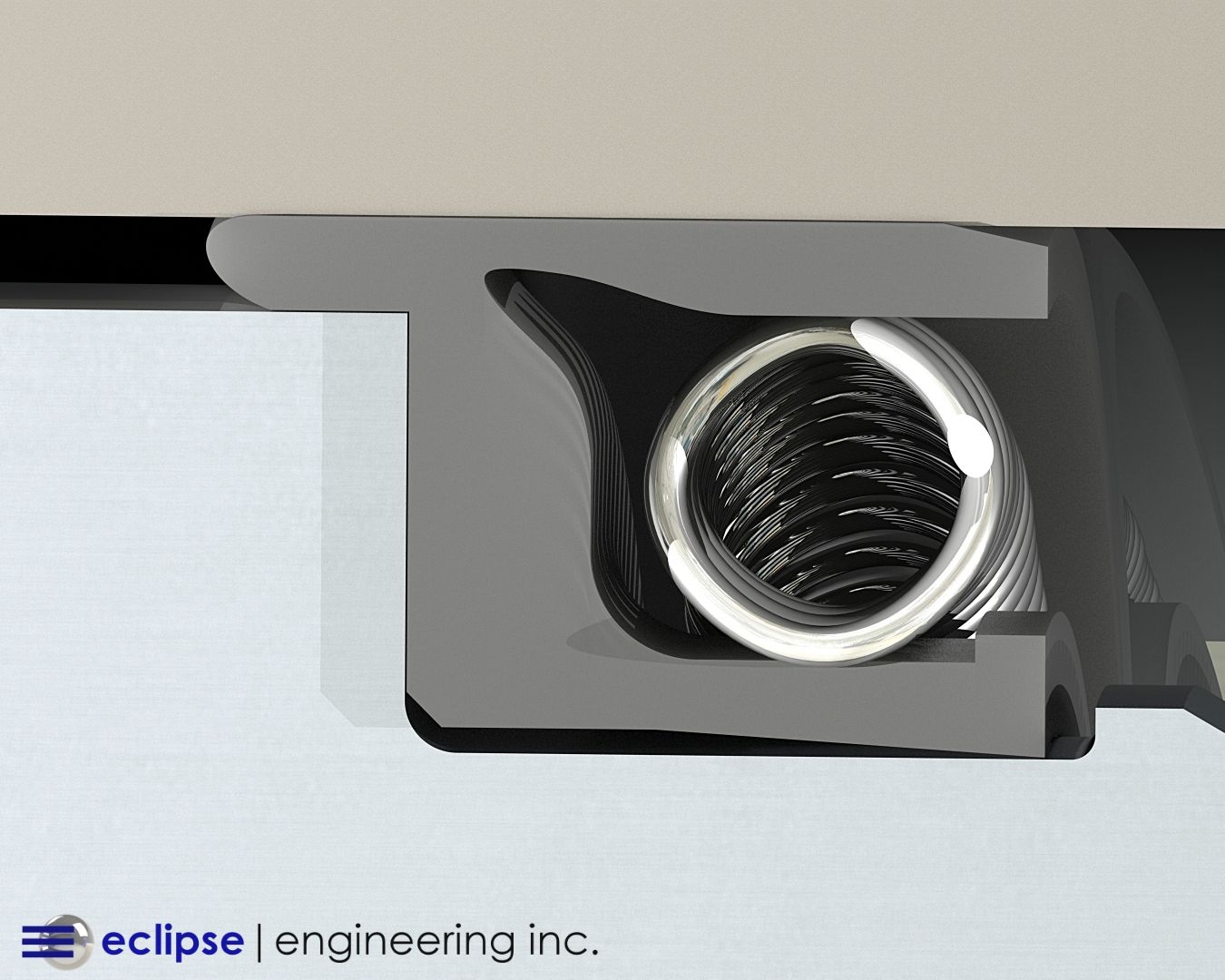

Metal springs, such as the Cantilever and Canted Coil spring , are used to energize polymers such as Teflon and UHMW to allow sealing in a wide range of temperatures. Selecting the correct spring material is critical to the life of the seal.

Metal energized seals are often subjected to a wide variety of fluids and temperature ranges, which then requires the correct material choice for the life of the seal in the application.

One of the earliest metal springs was the flat band or marcel expander, often made from common materials like 300 series Stainless Steel or heat treated 17-7 Stainless Steel.

These materials are often chosen for their tensile strength. But due to the cost to manufacture and the high volumes of spring required, these two expanders were often relegated to industrial or aerospace hydraulic systems.

If system fluids were not compatible with Stainless Steel, customers generally went to a different sealing system to avoid the high cost of short runs in these styles of energizers.

O-Rings cover a wide range of temperatures, and fluids, but generally not both. If there are multiple fluids involved, O-Rings often fail to provide compatibility over a range of fluids.

The use of Cantilever, Canted Coil or Helical coiled spring allowed for long runs and lower costs. The most common spring material is Stainless Steel, but these styles of spring lend themselves to materials that have a wide range of chemical and temperature range while maintaining tensile strength.

Alternative Spring Materials

Some of the more common alternative materials are Hastelloy and Elgiloy. While 17-7 is available, it’s seldom used because Elgiloy (while more expensive per pound) is often run at a higher volume, bringing the overall cost down making 17-7 less attractive due to cost.

Another style metal spring for polymers is the Garter spring. Garter springs are normally run on a per job basis, but because it’s made from wire, it can easily be wound from any material like Elgiloy or Stainless.

Garter springs are often used in rubber style lip seals, but we often find them coupled with polymer-style seals.

Mechanical Seals

Mechanical face seals typically marry a material with the fluids the seal will be running in. Mechanical seals have the overall body and internal springs made from specific materials capable of handling variations in temperature and fluids.

PEEK in Seals

Polymers are thought of as seal materials, but PEEK has been used as a spring in polymer-style seals. PEEK can be wound into helical style springs, and also formed into cantilever springs. As a Helical style, it can be wound into a diameter to energize Teflon or rubber lip seals.

If you consider radiation service, a PEEK spring makes an excellent choice keeping metals out of the seal.

How to Choose the Right Spring Material

While there are a variety of metals, often economics determine the practicality of specialty metals.

A consideration is reviewing the hardware used in the application as to what spring material is acceptable in an application. We often review what the customer is using in the rest of the service for determining a spring material.

Temperature is often a key factor in determining materials for spring. Elgiloy tends to do an excellent job in maintaining tensile strength at elevated temperatures.

Spring Manufacturing at Eclipse Engineering

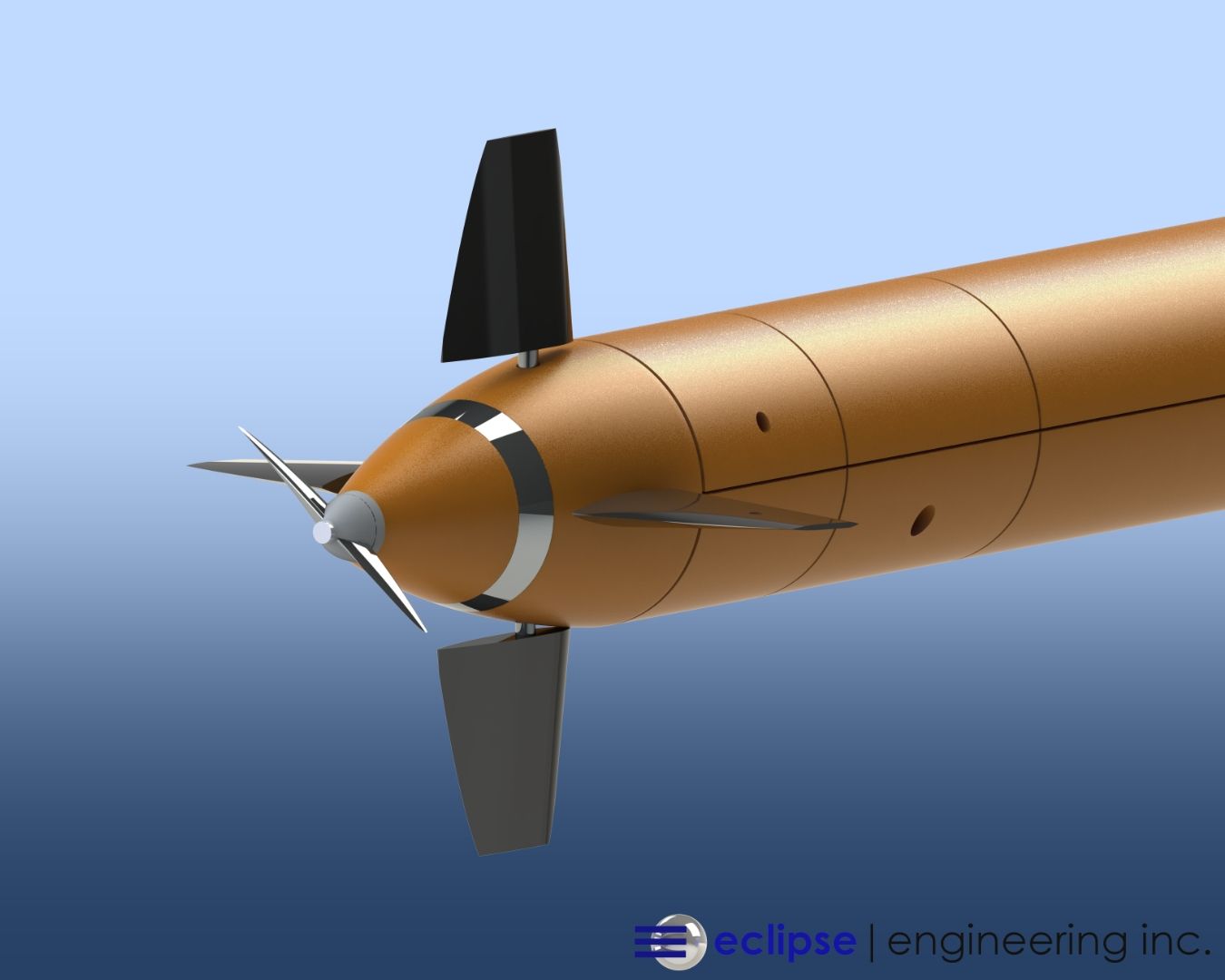

Eclipse Engineering is a manufacturer of a variety of Spring Energized Seals. We have the capability to design and build a seal with the exact seal and spring combination that meets your application needs, not just the one we “have on the shelf.”

We design in Canted Coil, Cantilever, Helical, and Garter spring. And we stock Stainless, Hastelloy, Elgiloy and of course a wide range of O-rings as energizers for our custom blended polymers.

Eclipse Engineering designs, manufactures, and distributes a wide range of products designed for applications found under, on and off the planet. We recognize the need for immediate response to keep pace with your manufacturing schedule.