Eclipse Engineering Blog

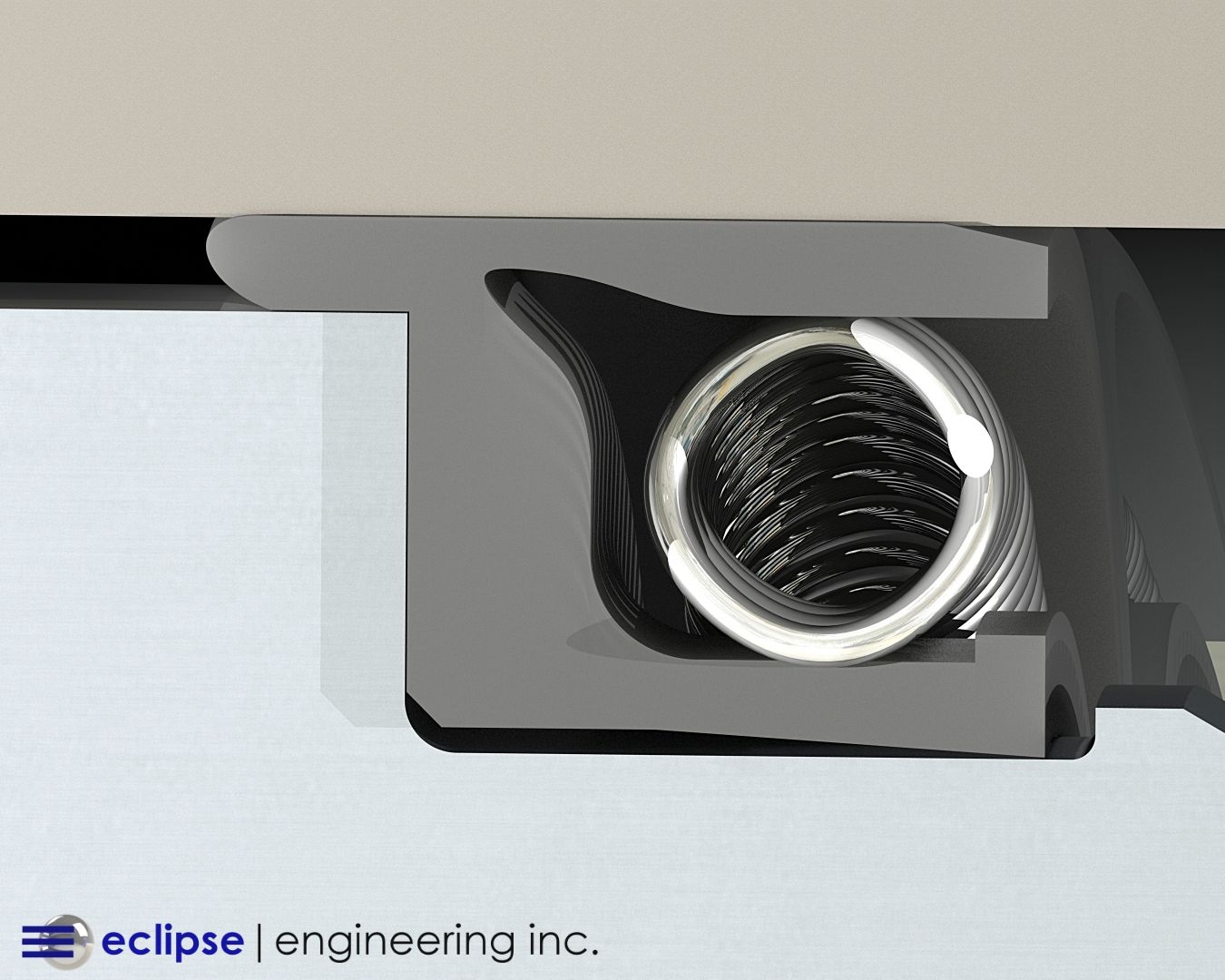

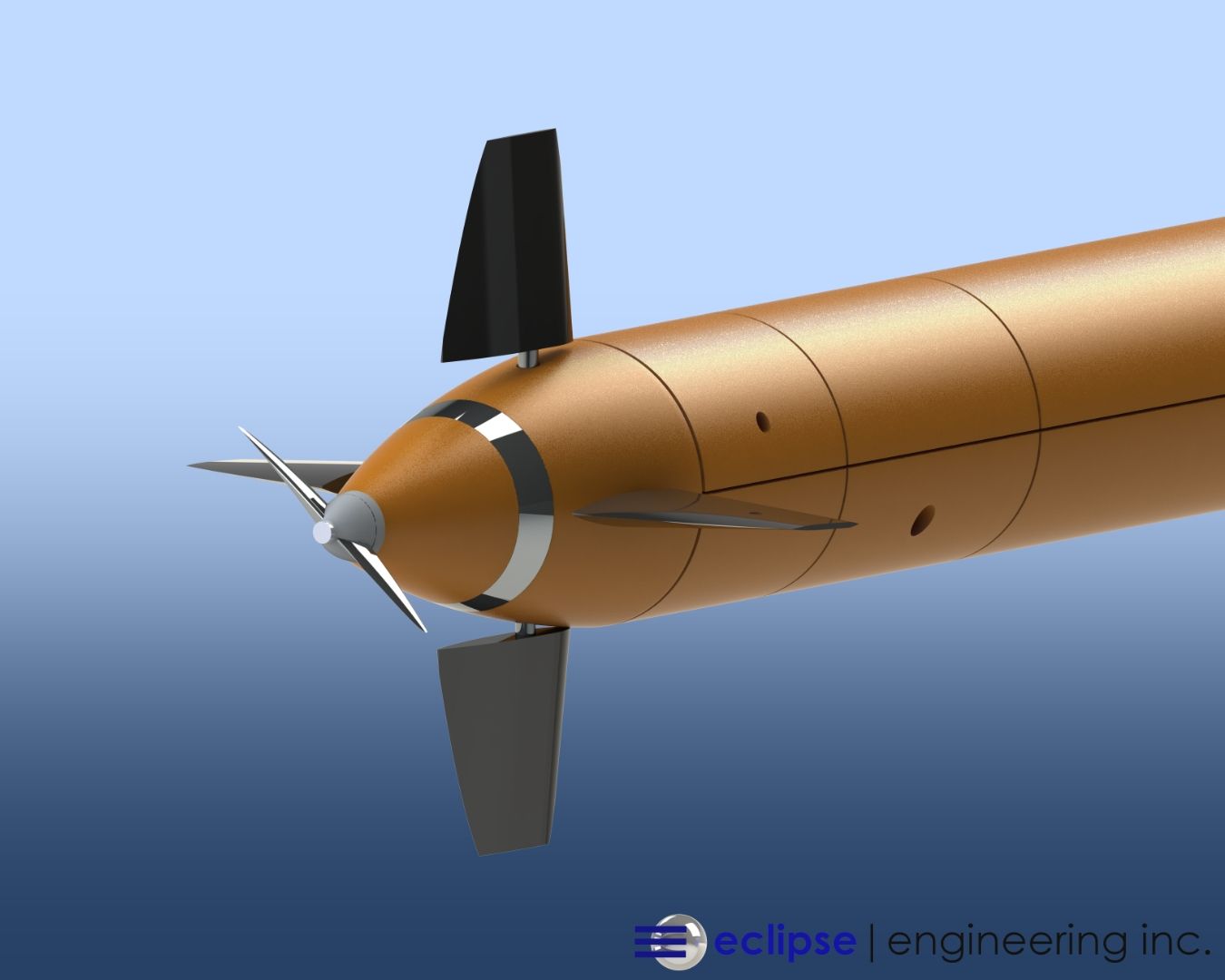

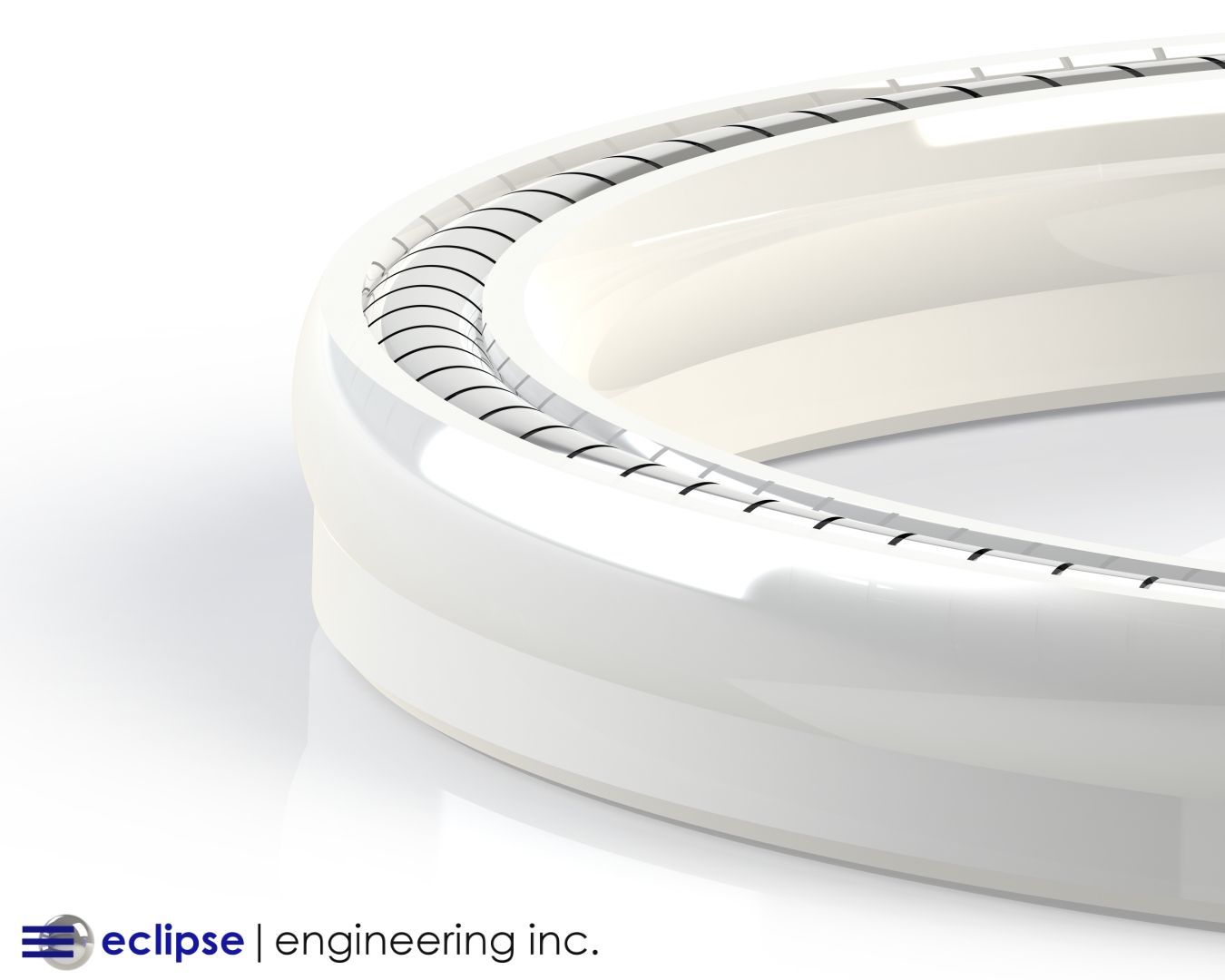

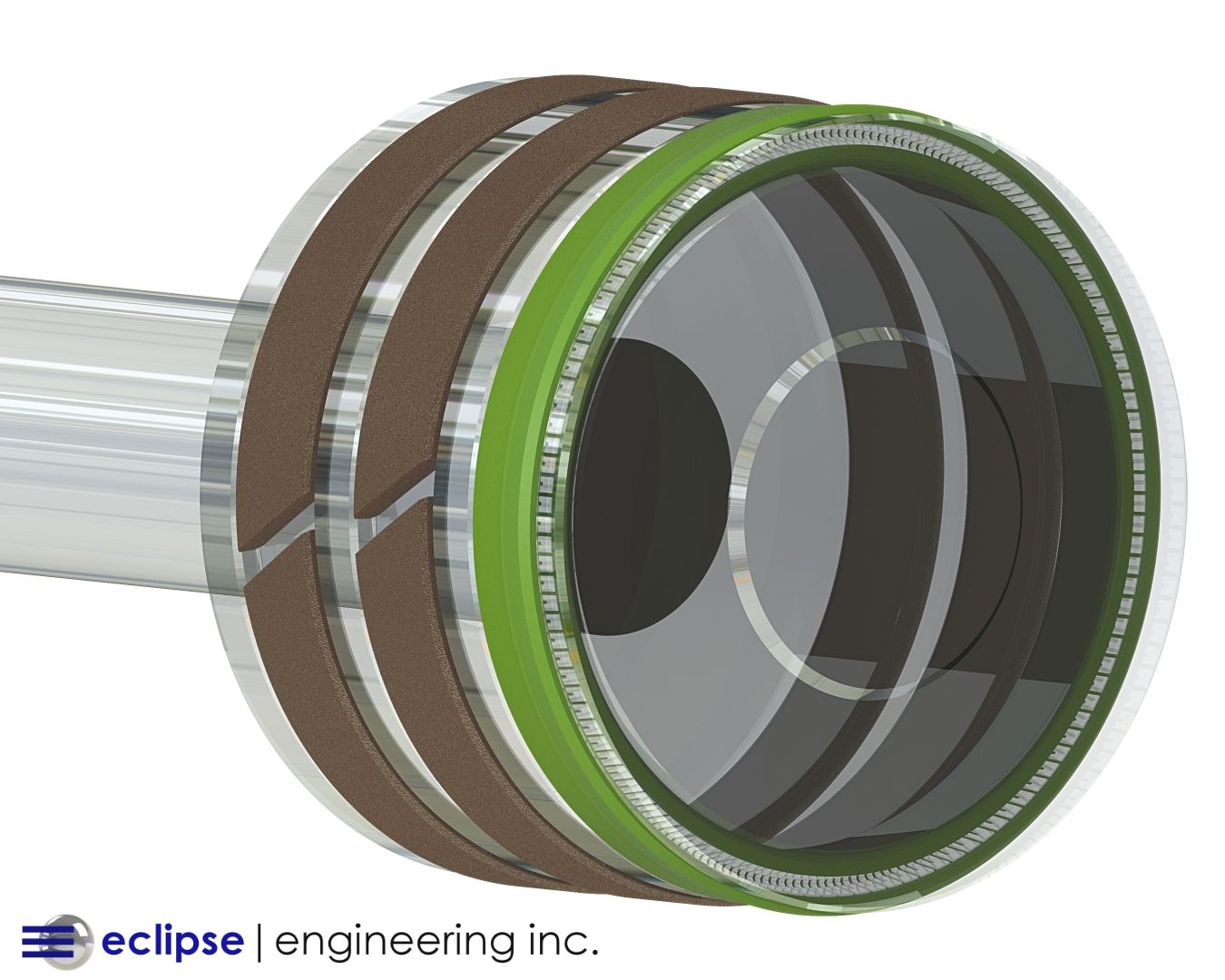

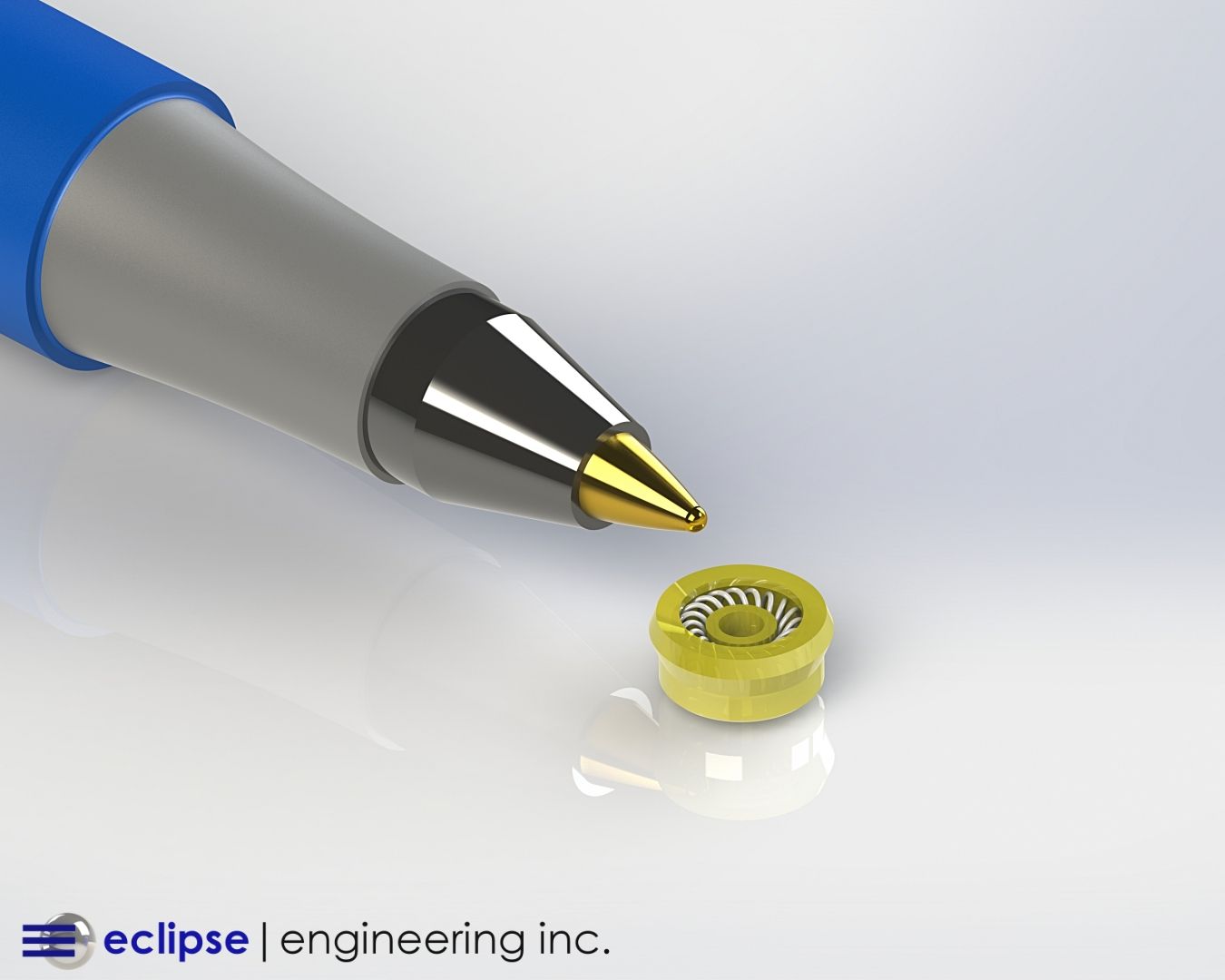

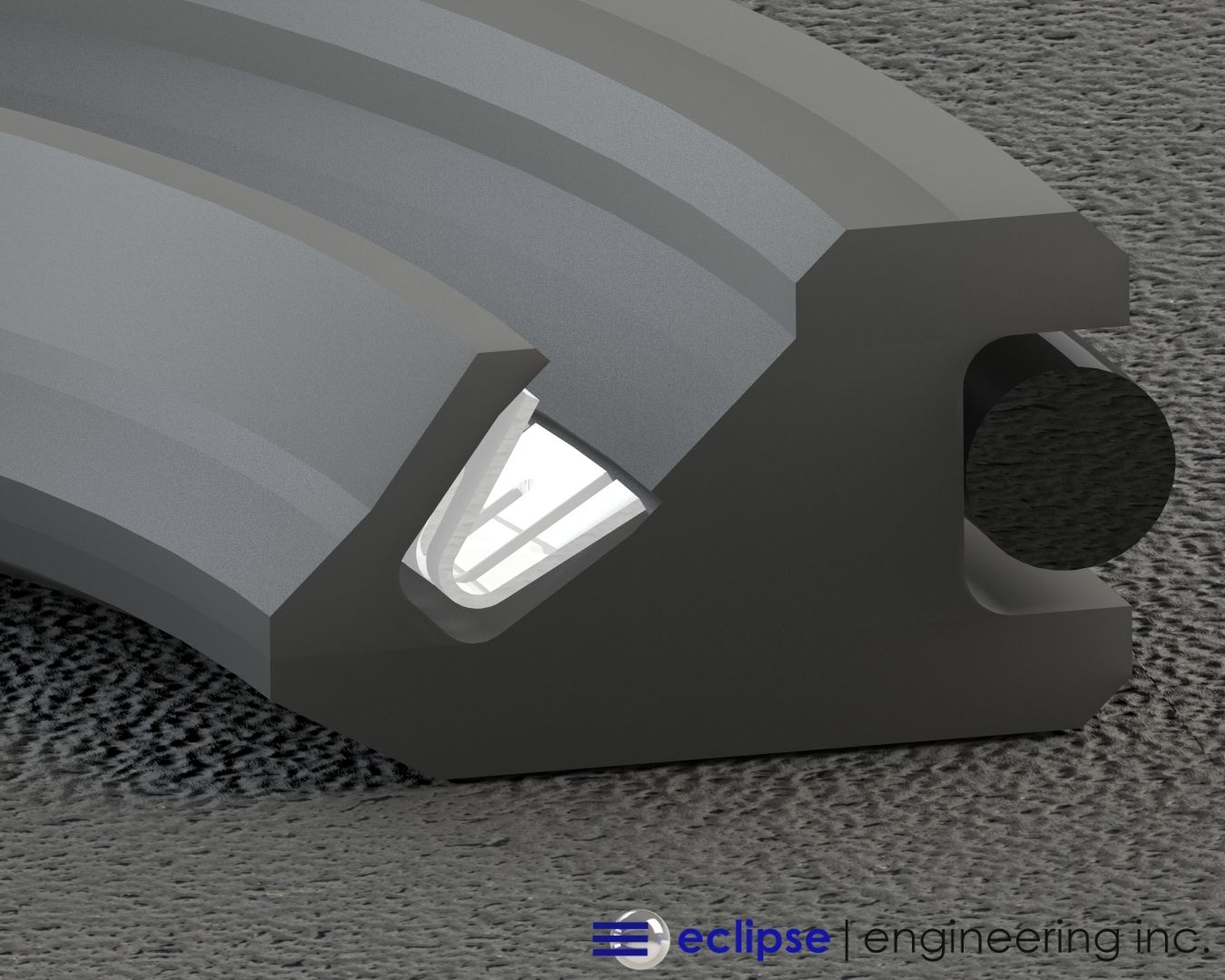

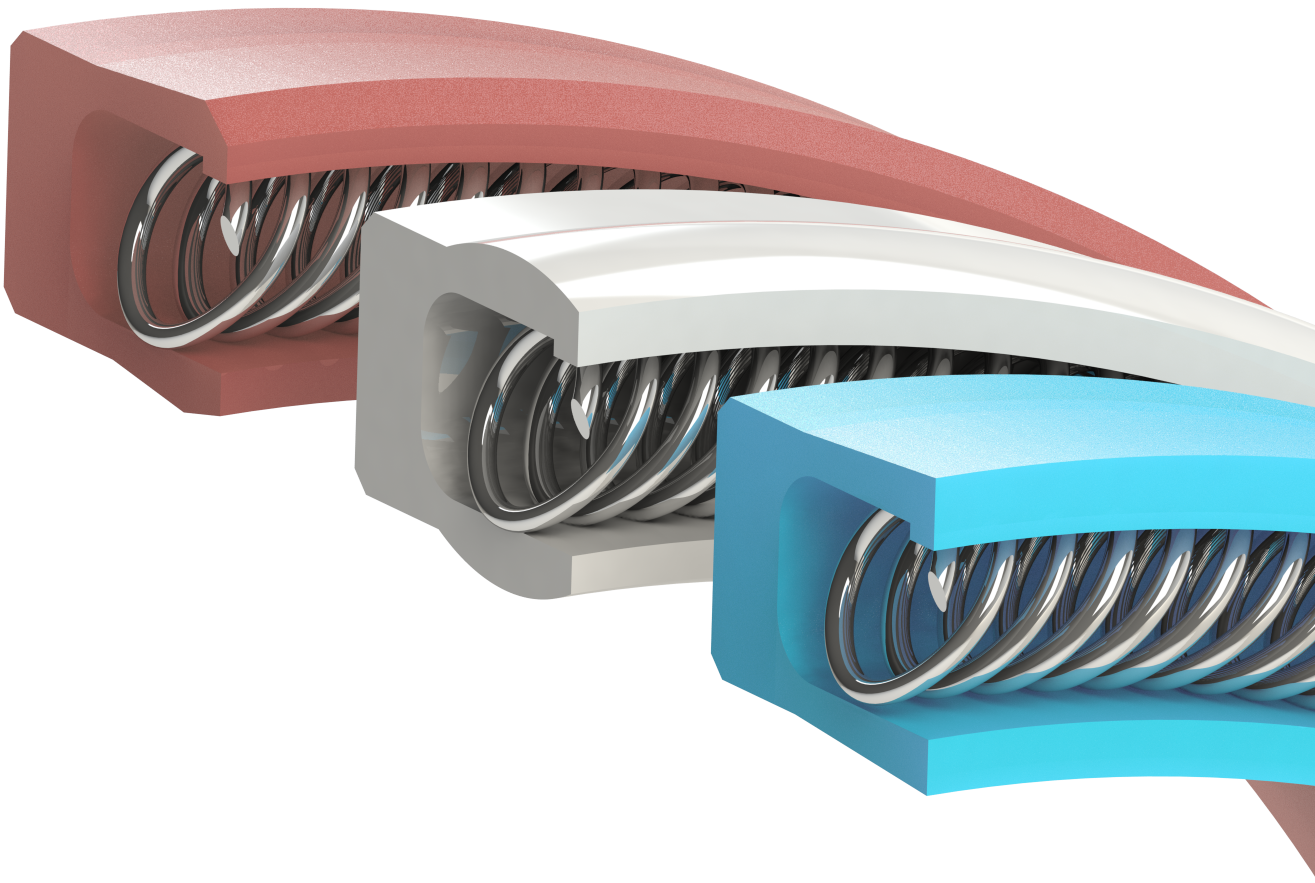

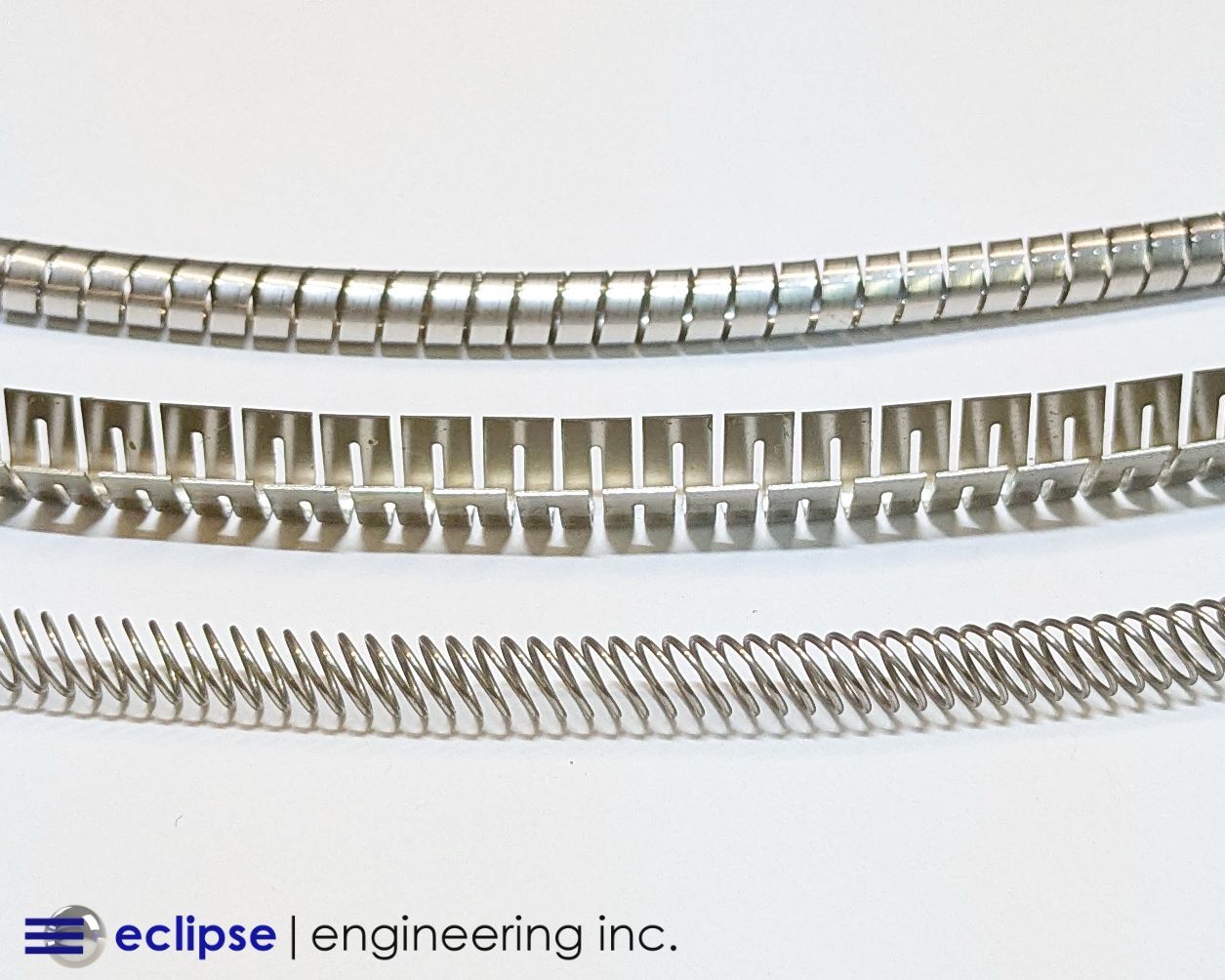

Aside from ball valve seats or non-contact labyrinth seals, PTFE is rarely used without a secondary energizer. This is due to PTFE’s inelastic nature. Unlike urethanes or elastomers which possess an inherent springiness, PTFE is often considered an “unalive” material. Much like a lump of clay, it will not bounce back once deformed. Especially in dynamic applications, this is not a desirable quality. Fortunately, with the addition of a spring or elastomer energizer, all of PTFE’s excellent attributes can be fully exploited in terms of sealing. Much like the rest of the seal industry, Eclipse utilizes three metallic spring energizer types for the seals we manufacture. Canted Coil, Cantilever V-Spring, and Helical. While each spring type ultimately accomplishes the same task, energizing a PTFE or polymer seal jacket, we’ll see that each type has unique properties better suited to certain applications. Figure 1 below shows generalized load versus deflection curves for the three spring types. As you can see, each one is quite a bit different, favoring distinct circumstances and applications. Though, we’ll also find out load curves are not only deciding factor when choosing a spring.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!