Thermoplastic Elastomer | EH

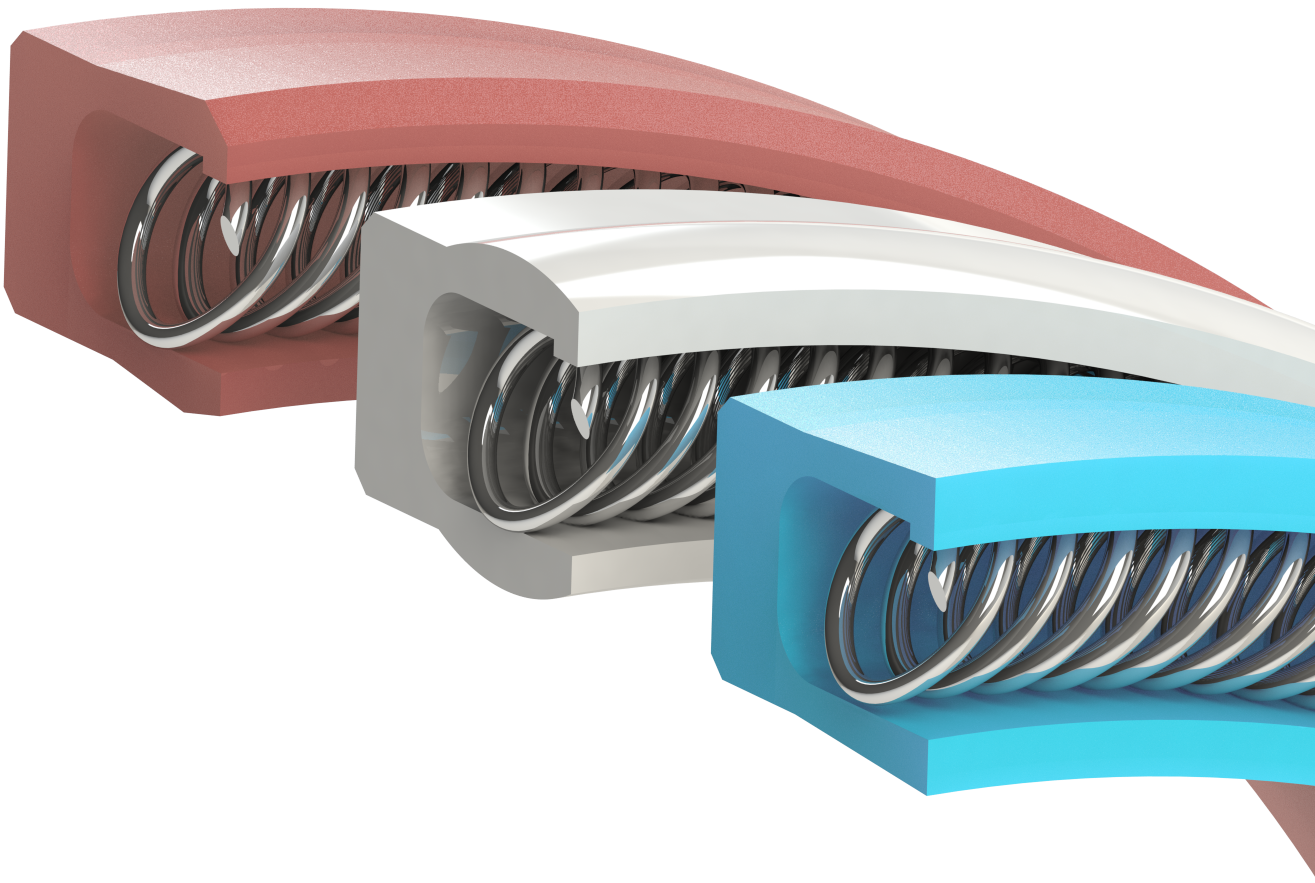

Eclipse EH materials are a class of materials derived from thermoplastic elastomer resins. They are unique in the fact that they are constructed from a copolymer system that connects high modulus thermoplastics with high elongation elastomers. The resulting combination yields a product that is extremely tough, yet still flexible enough to be used for seal elements. EH materials have similar properties to urethanes in terms of flexibility and tear resistance, but can be both machined and injection molded to complex shapes. This material class has excellent resistance to hydrocarbon media making it useful in the automotive products. EH materials also have low permeability making it a useful material in gaseous media.

Available Materials

(Beige) Medium modulus grade, with nominal durometer hardness of 55D. It is specially stabilized version for superior heat and oil resistance properties.

(Black) Medium modulus grade, with nominal durometer hardness of 55D. It is specially stabilized version for superior heat and oil resistance properties.

(Beige) Medium modulus grade, with nominal hardness of 55D. It contains non-discoloring stabilizer.

(Black) Medium modulus grade, with nominal hardness of 55D. It contains non-discoloring stabilizer.

(Beige) High modulus grade, with nominal hardness of 72D. It contains non-discoloring stabilizer.

(Black) High modulus grade, with nominal hardness of 72D. It contains non-discoloring stabilizer.

Notice:

Technical Information, test data and advice provided by Eclipse Engineering are based on information and tests we believe to be reliable and are intended for persons with knowledge and technical skill sufficient to analyze test types and apply adequate safety factors for the given application. Because actual application conditions vary widely, these values are intended for comparitive purposes only and the suitability of this material is ultimately left to the end user.

EH041

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ISO 1183 | 1.19 | - |

| Tensile Strength at Break | ISO 527 | 2200 | psi |

| Elongation at Break | ISO 527 | 520 | % |

| Hardness | ISO 868 | 55 | Shore D |

EH042

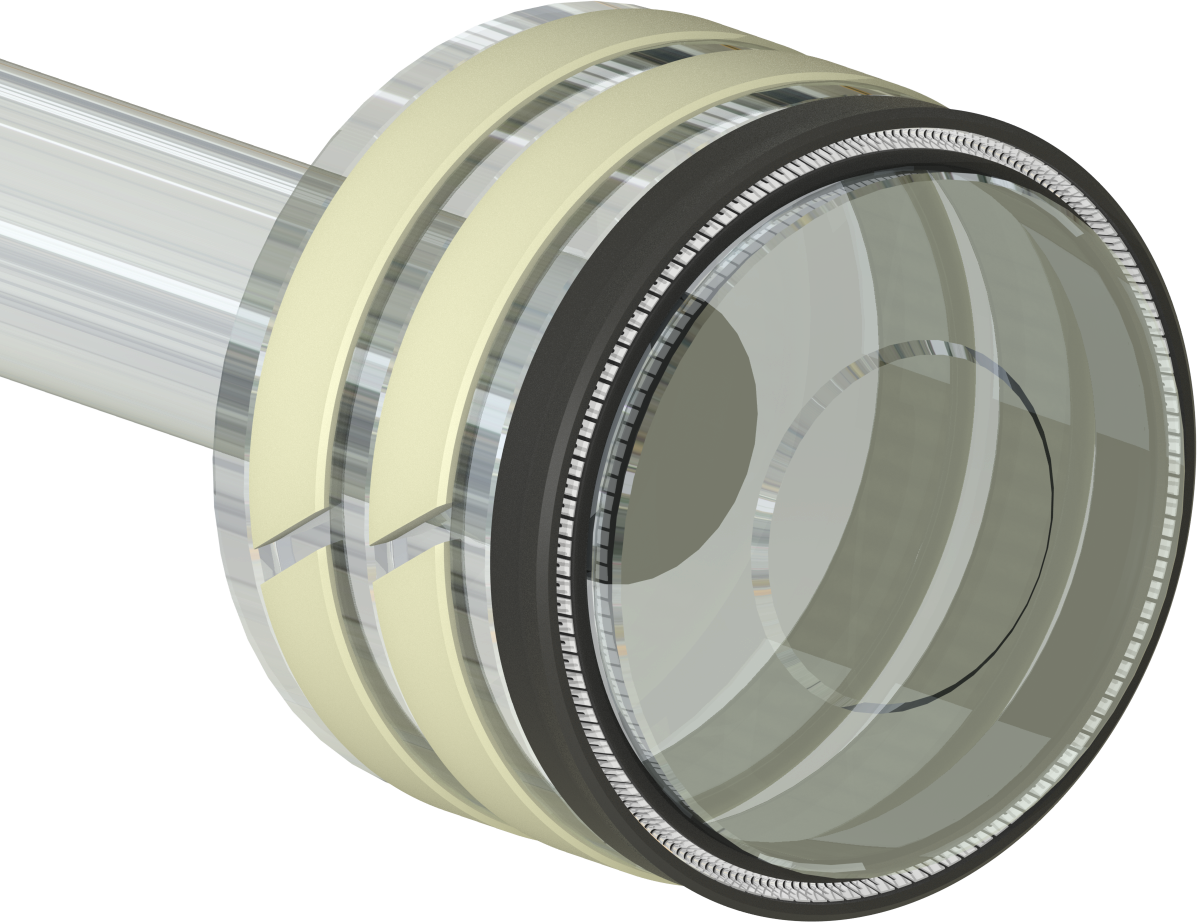

With the toughness of high modulus plastic and the flexibility of rubber, Eclipse EH042 makes an excellent choice for a seal when application requirements dictate tight leakage control. When combined with an Eclipse spring energizer, very tight sealing can be achieved. EH042 does not have the temperature range or chemical compatibility of PTFE materials, but when operating under 250°F (121°C) it out performs those materials in sealing performance. EH042 is suggested in gaseous media such as nitrogen, oxygen and hydrogen.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ISO 1183 | 1.19 | - |

| Tensile Strength at Break | ISO 527 | 2200 | psi |

| Elongation at Break | ISO 527 | 520 | % |

| Hardness | ISO 868 | 55 | Shore D |

EH043

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ISO 1183 | 1.19 | - |

| Tensile Strength at Break | ISO 527 | 6000 | psi |

| Elongation at Break | ISO 527 | 500 | % |

| Hardness | ISO 868 | 55 | Shore D |

EH044

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ISO 1183 | 1.19 | - |

| Tensile Strength at Break | ISO 527 | 6000 | psi |

| Elongation at Break | ISO 527 | 500 | % |

| Hardness | ISO 868 | 55 | Shore D |

EH045

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ISO 1183 | 1.26 | - |

| Tensile Strength at Break | ISO 527 | 7700 | psi |

| Elongation at Break | ISO 527 | 450 | % |

| Hardness | ISO 868 | 72 | Shore D |

EH046

Eclipse EH046 utilizes the same chemistry as EH042 but with a higher durometer (72 Shore D versus 55 Shore D). This higher durometer allows EH046 to be used as high pressure back-up rings providing exceptional extrusion resistance.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ISO 1183 | 1.26 | - |

| Tensile Strength at Break | ISO 527 | 7700 | psi |

| Elongation at Break | ISO 527 | 450 | % |

| Hardness | ISO 868 | 72 | Shore D |

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!