Composite | EC

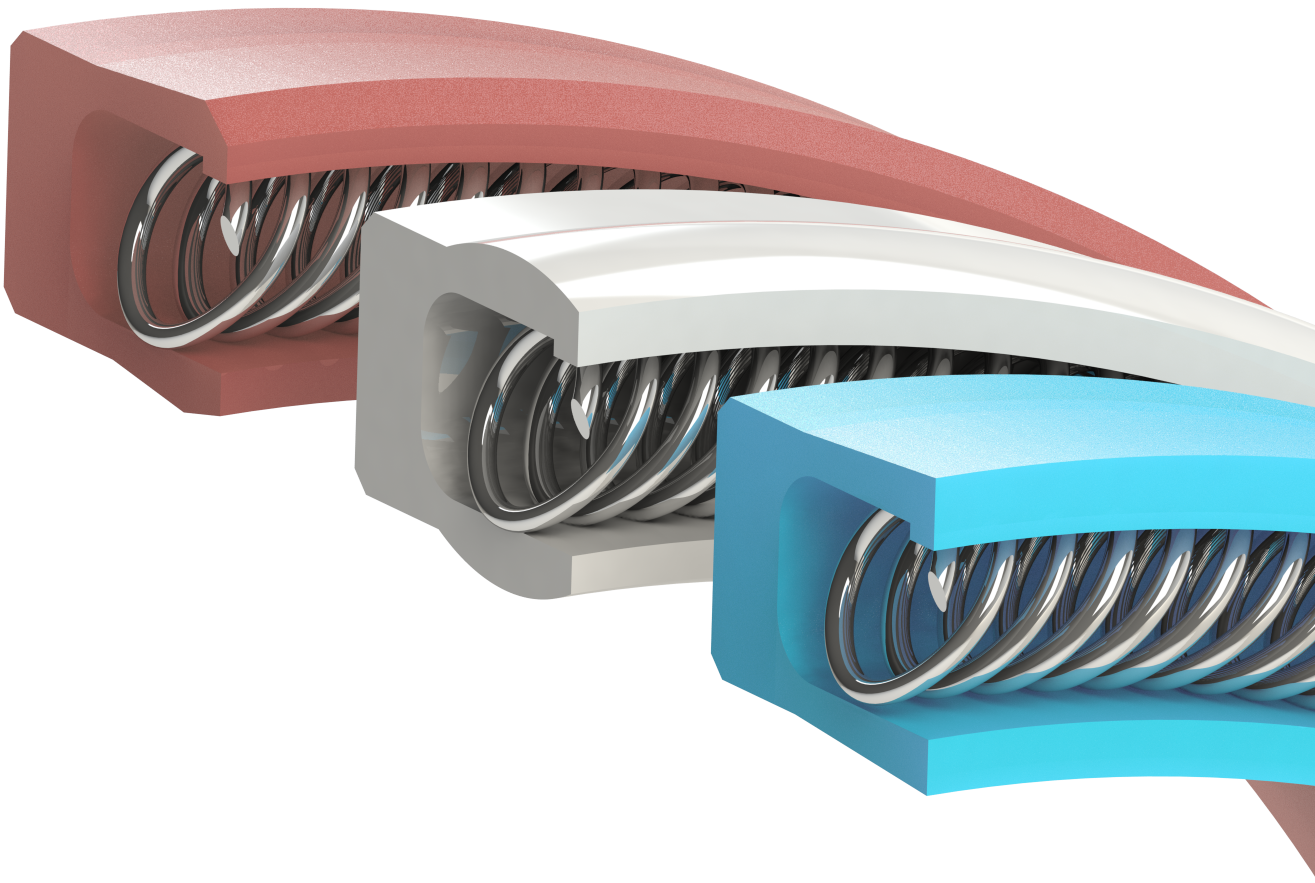

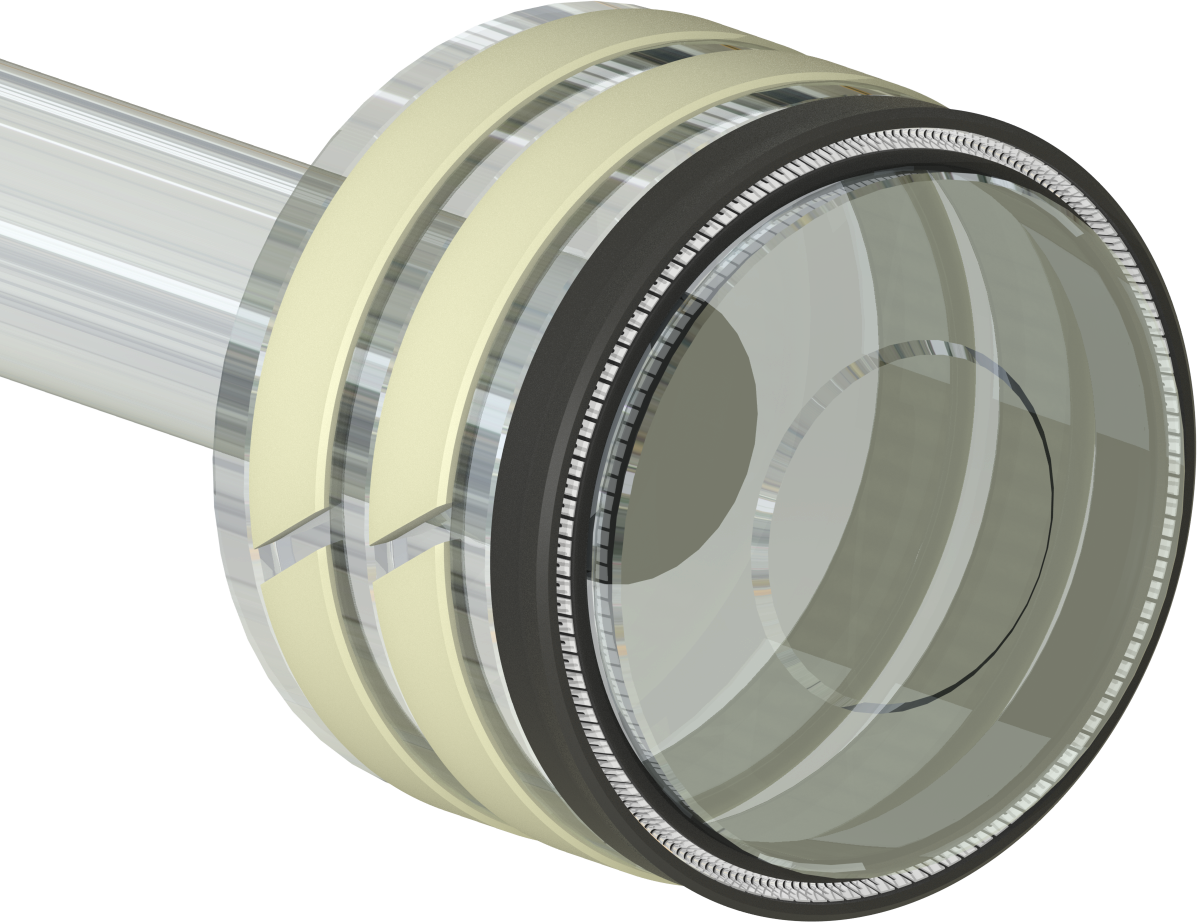

Eclipse EC materials are unique in the fact that they are manufactured by combining structural fabrics with resin. A true composite material, EC formulations utilize the abrasion resistance of woven fabrics with the compressive rigidity of thermosetting resin. The resulting material offers exceptional compressive strength characteristics that lend themselves directly to being used as wear components. As such, EC materials are most commonly specified for wear rings, thrust washers, and linear guides. These materials display compressive strengths double or triple those of high cost engineering plastics. What this means in practice, is that highly load-capable, high wearing bearings can be designed with minimal footprint. Additionally, since less raw material is required to perform the same load function, EC materials should be considered on a cost effective basis as well.

Eclipse EC wear components make a perfect complement to Eclipse seals and scrapers particularly in reciprocating applications such as hydraulic cylinders. In addition to the standard EC131 formulation, Eclipse offers high temperature resin and internally lubricated versions. Eclipse EC materials can be found in applications such as automotive transmissions, process impeller shafts as well as water service in marine and dam applications

Available Materials

Notice:

Technical Information, test data and advice provided by Eclipse Engineering are based on information and tests we believe to be reliable and are intended for persons with knowledge and technical skill sufficient to analyze test types and apply adequate safety factors for the given application. Because actual application conditions vary widely, these values are intended for comparitive purposes only and the suitability of this material is ultimately left to the end user.

EC131

This is a self lubricating industrial grade composite very commonly used in reciprocating hydraulics. Manufactured from continuous layers of medium weave polyester fabric bonded with polyester resin. A very cost effective material for wear rings and bushings. The evenly dispersed PTFE allows a degree of dry running service and reduces friction for smooth operation. When used at moderate temperatures (200°F, 93°C or less) EC131 can be specified in a wide variety of applications such as wear pads, conveyor guides and thrust washers. With water absorption less than 0.1%, it can also be specified for wet applications such as trunion bushings in dam gates.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Tensile Strength | internal | 9,500 | psi |

| Compressive Strength Normal | internal | 35,000 | psi |

| Compressive Strength (Ultimate) | internal | 30,000 | psi |

| Compressive Strength (Parallel) | internal | 13,500 | psi |

| Density | internal | 0.045 | lbs/in³ |

| Water Absorption | internal | - | <.1% |

EC323

This is a high temperature composite capable of carrying significant loads up to 400°F (204°C). For this reason, EC323 has replaced traditional polymer and metallic materials in bearings seen in foundries, gas flow control valves and regenerators. The MoS2particulate lubricator is finely dispersed, allowing for smooth, non-galling operation. Additionally, the low friction properties negate stick-slip problems associated with machinery that is expected to operate smoothly after long idle periods.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | internal | 1.87 | - |

| Ultimate Compressive Strength | internal | 60,000 | psi |

| Unit Load Limit | internal | 30,000 | psi |

| Temperature Range | internal | ±325 | °F |

| Coefficient of Thermal Expansion | internal | 7.0 x 10^-6 | in/in/°F |

| Water Absorption (24 hr) | internal | 0.16 | % |

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!