External Face Spring Seals

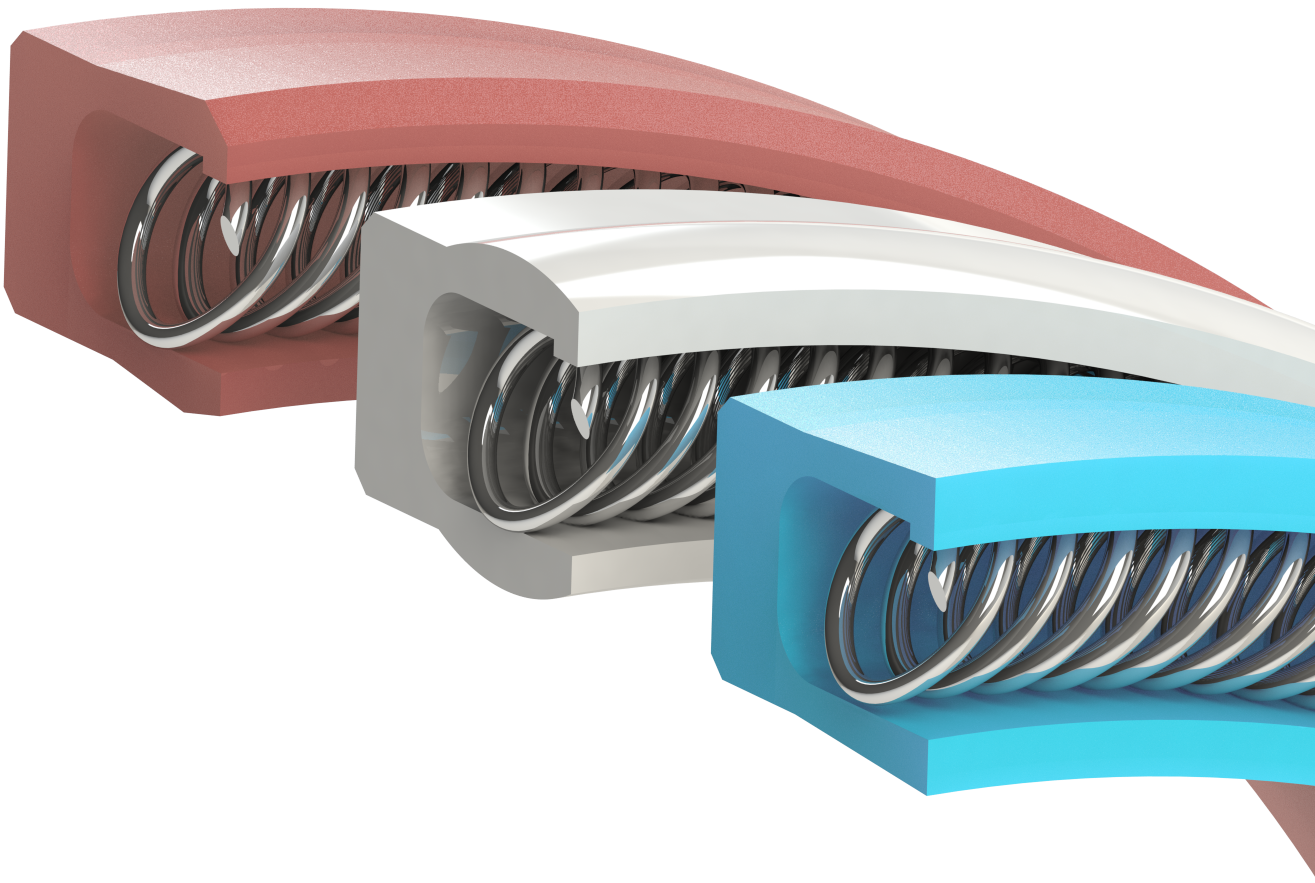

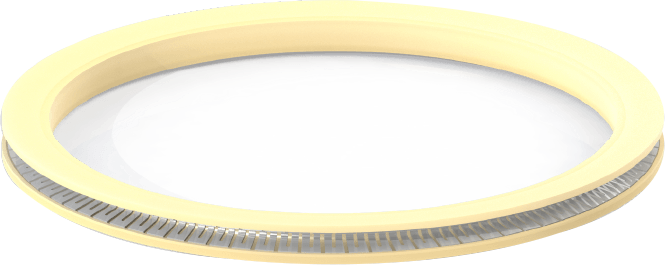

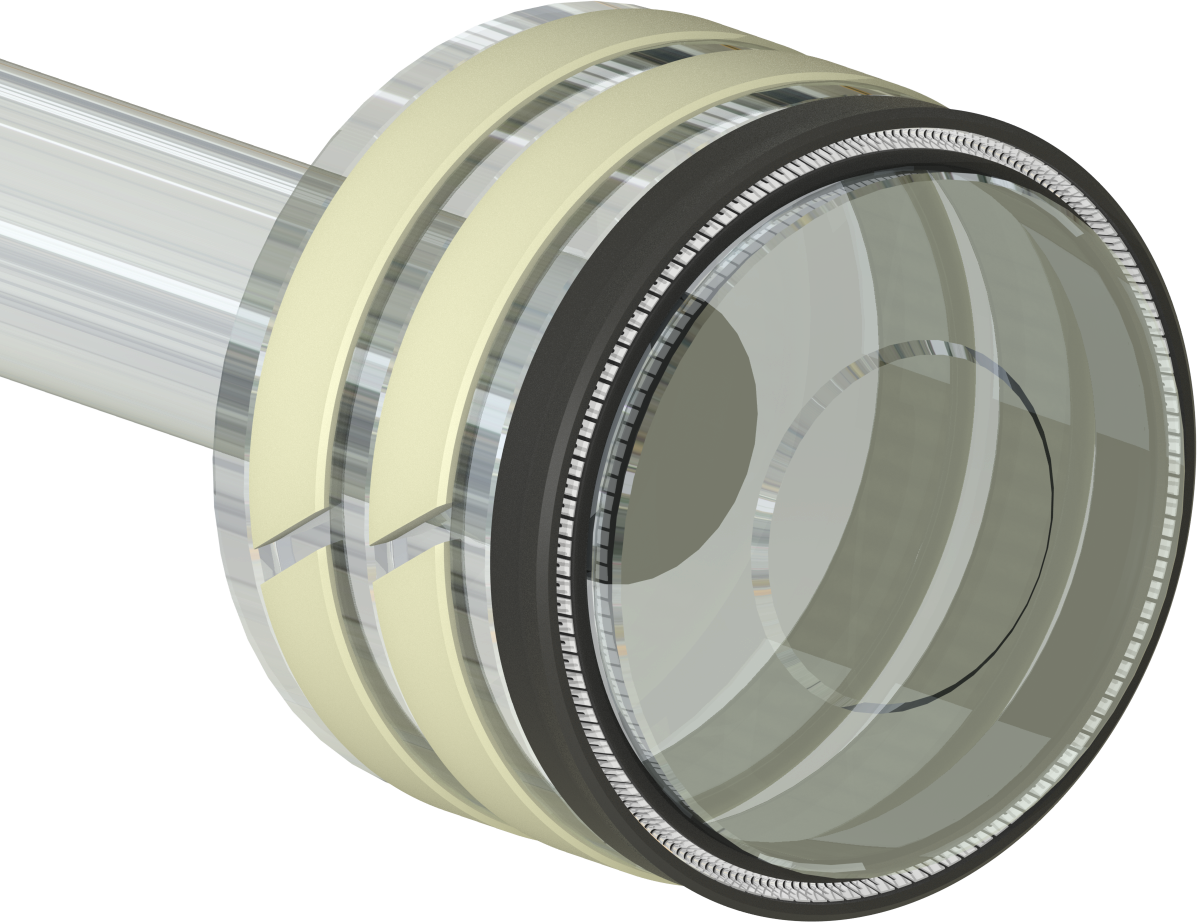

External Face Seals are specialized components typically used in static sealing applications to protect critical mechanical connections from environmental contaminants. These seals are crucial for ensuring the integrity of exposed joints, hinge points, or pipe fittings, effectively preventing the entry of dirt, moisture, and other environmental contaminants.

PTFE Face Seals offer significant advantages over traditional O-Rings due to their superior pressure handling, extensive chemical compatibility, and broad operating temperature range. This makes them ideal for applications that require robust durability and reliability. They’re especially effective in cryogenic applications where extreme temperatures demand sturdy sealing solutions.

Such seals are crafted using advanced materials like PTFE and UHMW-PE, which are selected for their low friction properties and resistance to chemical corrosion. This makes External Face Seals particularly effective in harsh environments, such as those involving corrosive chemicals or where cleanliness and contamination control are critical.

External Face Seals are commonly found in industries ranging from aerospace, where they protect systems against harsh atmospheric conditions, to pharmaceuticals, where maintaining a sterile environment is essential. Their versatility also extends to hydraulic and pneumatic systems, reinforcing their role in maintaining system efficiency and safety.

Overall, External Face Seals represent a crucial element in modern industrial design, providing a reliable sealing solution that supports a wide array of technological and engineering applications. Their ability to perform under pressure, across a spectrum of temperatures, and in the face of chemical exposure makes them an indispensable choice for today’s industries.

What you'll get out of these product modules

Our product modules offer an in-depth step-by-step guide to help make choosing and ordering the right product for your project easy.

With every product module you’ll receive the following:

- Introduction to the product and a typical range of applications including temperature, pressure, velocity and media.

- Detailed ordering examples and product illustrations.

- Chart of standard seal materials including eclipse material code, description, color and applications.

- Chart of standard part numbers including part number, rod Ø, groove Ø, groove width and o-ring dash size.

- Hardware details including a cross section series, min rod ø for solid gland installation, r radius (max) and c lead-in chamfer (min).

Why Choose Eclipse?

We offer custom solutions to a wide variety of seal needs that span various industries, from aerospace to automotive to mountain bike design.

Quality Products

Eclipse was the first supplier to offer a full range of materials that meet the latest SAE spec AMS3678, which requires a high degree of testing and certification to meet the needs of our most discriminating customers.

Fast Turnaround

We understand your time is valuable. That’s why we work to get your product designed and delivered fast, eliminating downtime and saving you money.

Competitive Pricing

We stay ahead of the game with the best prices for the best quality of product in the industry.

Why Choose Eclipse?

Eclipse was founded under the premise that if we could solve enough of our customers’ problems they would continue to come back to us for solutions regardless of the type of products we offered.

Eclipse has evolved to produce standard product o-rings for a wide range of industries including Hydraulics, Pneumatics, Energy Production, Aerospace as well as Pharmaceutical and Food Handling. Instituting ISO9001/AS9100 quality system in 2015 allowed Eclipse to become a top tier supplier.

Today, Eclipse can support our smaller customers that require only a few seals a year to those needing in the 100’s of thousands. We continue to retain a quality product and are able to deliver consistently on time. Our customers continue to bring us challenging projects that allow our team to do what we do best, problem solving.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!