ECLIPSE EVSC – CASED CANTILEVER SPRING ENERGIZED SEAL

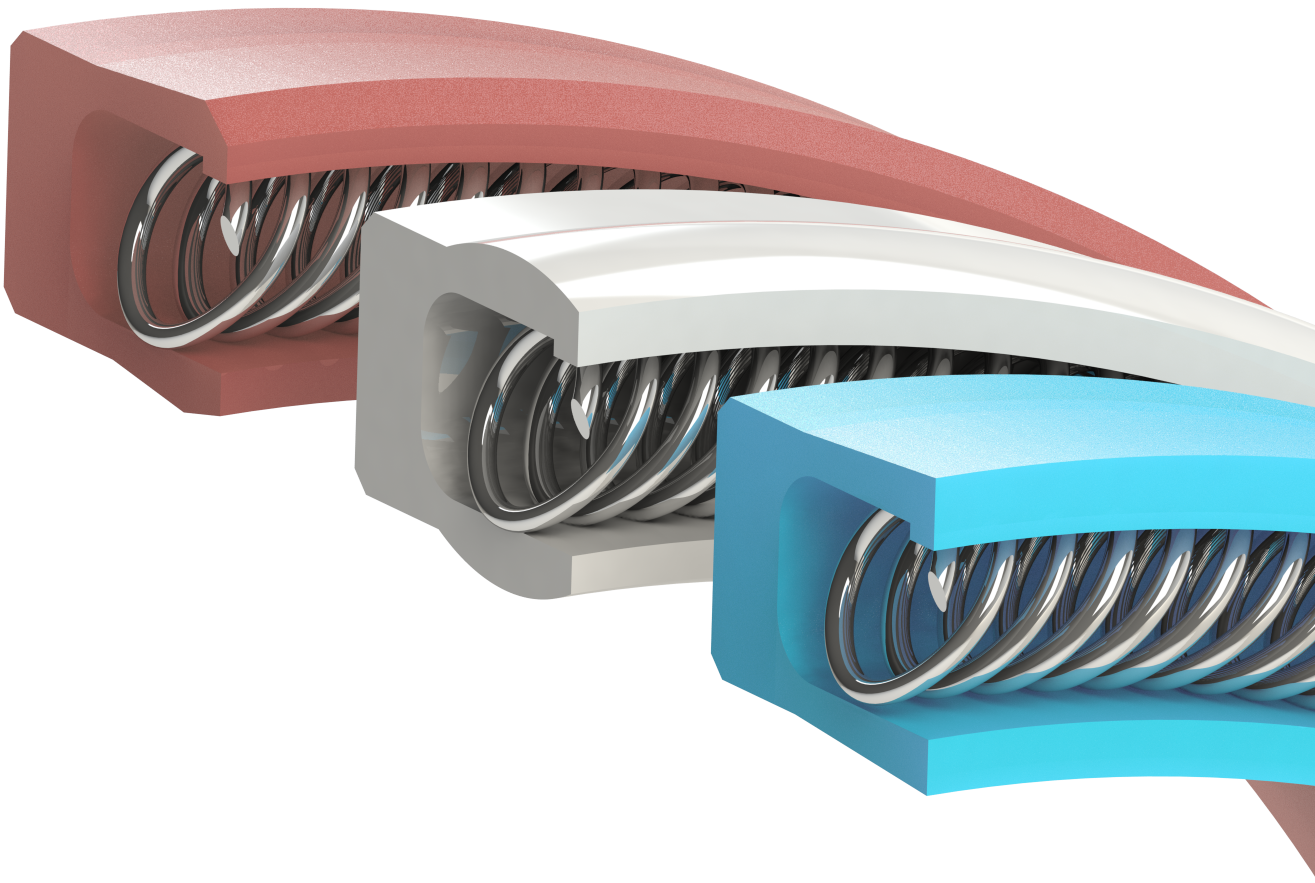

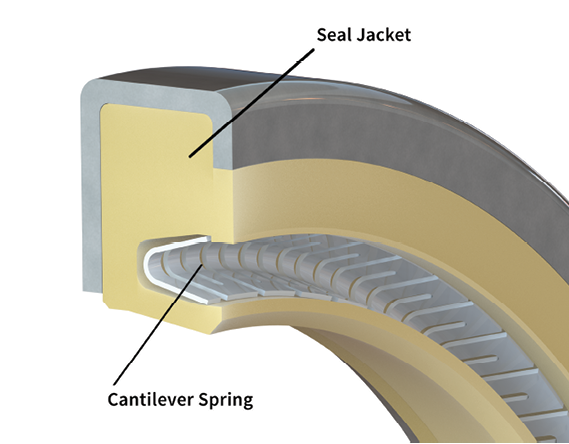

Cased Spring Seals are the best option for extreme rotary service. In these designs, a metal case is constructed around the outside of a spring seal, which in turn gets press-fit into the hardware bore. A metal-to-metal press-fit ensures a tight seal as well as a highly effective anti-rotation mechanism. Because these seals are installed into open bores, they lend themselves to rotary applications such as gearboxes and power transmission systems. They can also be utilized as rod end scrapers, where exclusion of aggressive media is desired.

Typical Range of Application

Pressure

Vacuum to 3,000 psi

[0 to 200 bar]

Temperature*

-320°F to 450°F

[-195°C to 230°C]

Ratings will vary based on materials and operating conditions

Values and ratings in this catalog are based on industry standard applications operating under ideal conditions. The customer should assume responsiblity for validation testing of performance and suitabilty of Eclipse Engineering products. Eclipse Engineering accepts no liabilty for the accuracy and applicabilty of provided information.

STANDARD ORDERING EXAMPLE:

EVSC-R-548-LW-ET006-M-S-S

| EVSC | = Seal Series | |

| R | = Rod | |

| 548 | = Dash Number | |

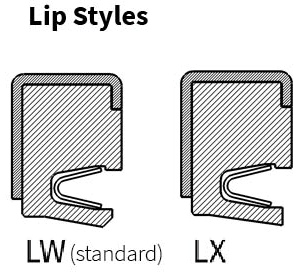

| LW | = Lip Style | |

| ET006 | = Seal Material Code | |

| M | = Spring Load L – Light M – Medium H – Heavy | |

| S | = Spring Material S – Stainless Steel E – Elgiloy® H – Hastelloy® | |

| S | = Case Material S – Stainless Steel A – Aluminum |

NON-STANDARD ORDERING EXAMPLE:

EVSC-R-C-02953-LW-ET006-M-S-S

C

= Nominal Cross-Section

A = 1/4 in. (400 Series)

B = 5/16 in. (500 Series)

C = 3/8 in. (600 Series)

D = 7/16 in. (700 Series)

E = 1/2 in. (800 Series)

02953

= Rod Diameter in 1000ths

Example: 02953 = Ø2.953 [75MM] Rod Diameter

EVSC STANDARD SEAL MATERIALS

| ECLIPSE MATERIAL CODE | DESCRIPTION | COLOR | APPLICATIONS |

|---|---|---|---|

| ET000 | Virgin PTFE | White | Light Duty / Static / Cryogenics |

| ET006 | Carbon filled PTFE | Black | General Purpose |

| EU000 | Virgin UHMWPE | Translucent White | Viscous Media / Water |

| ET014 | Polyimide filled PTFE | Orange/Brown | High Sealabilty / Soft Hardware |

EVSC STANDARD SPRING MATERIALS

| ECLIPSE MATERIAL CODE | SPRING MATERIAL | APPLICATIONS |

|---|---|---|

| S | 300 Series Stainless Steel | General purpose, standard spring material |

| E | Elgiloy® | Improved performance and corrosion resistance; NACE approved |

| H | Hastelloy® C276 | Maximum chemical/corrosion resistance |

See Eclipse Material Guide for complete list of available materials.

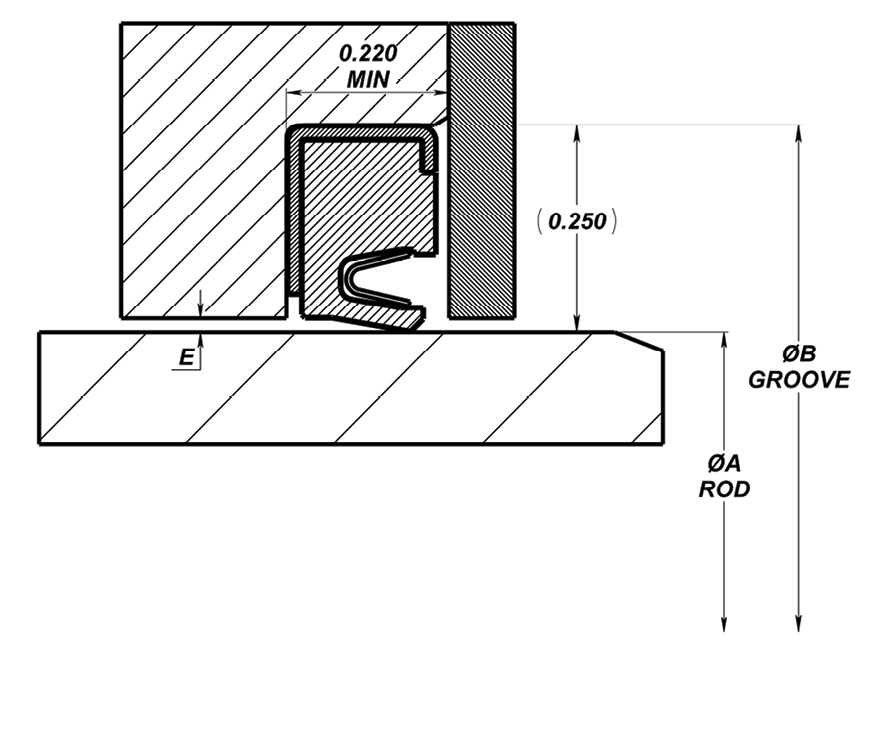

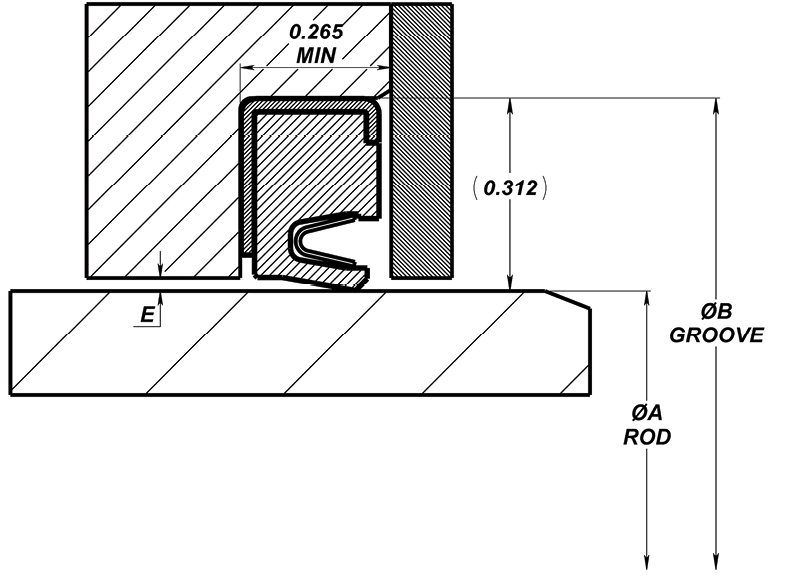

400 SERIES STANDARD DASH NUMBERS

| Gland tolerances | ||

|---|---|---|

| SEAL ID | ØA | ØB |

| 0.125 to 0.374 | +0.000

-0.001 |

± 0.001 |

| 0.375 to 2.999 | +0.000

-0.002 |

± 0.001 |

| 3.000 to 5.999 | +0.000

-0.003 |

± 0.0015 |

| 6.000 and up | +0.000

-0.004 |

± 0.002 |

| 400 Series Maximum Extrusion Gap (E), at 70° F | ||

|---|---|---|

| 300 psi | 1500 psi | 3000 psi |

| 0.010 | 0.006 | 0.004 |

Consult Eclipse Engineering for all custom or unlisted sizes.

400 SERIES STANDARD DASH NUMBERS:

| DASH # | A | B |

|---|---|---|

| 404 | 0.250 | 0.750 |

| 405 | 0.313 | 0.813 |

| 406 | 0.375 | 0.875 |

| 407 | 0.438 | 0.938 |

| 408 | 0.500 | 1.000 |

| 409 | 0.563 | 1.063 |

| 410 | 0.625 | 1.125 |

| 411 | 0.688 | 1.188 |

| 412 | 0.750 | 1.250 |

| 413 | 0.813 | 1.313 |

| 414 | 0.875 | 1.375 |

| 415 | 0.938 | 1.438 |

| 416 | 1.000 | 1.500 |

| 417 | 1.063 | 1.563 |

| 418 | 1.125 | 1.625 |

| 419 | 1.188 | 1.688 |

| 420 | 1.250 | 1.750 |

| 421 | 1.313 | 1.813 |

| 422 | 1.375 | 1.875 |

| 423 | 1.438 | 1.938 |

| 424 | 1.500 | 2.000 |

| 425 | 1.563 | 2.063 |

| 426 | 1.625 | 2.125 |

| 427 | 1.688 | 2.188 |

| 428 | 1.750 | 2.250 |

| 429 | 1.813 | 2.313 |

| 430 | 1.875 | 2.375 |

| 431 | 1.938 | 2.438 |

| 432 | 2.000 | 2.500 |

| 433 | 2.063 | 2.563 |

| 434 | 2.125 | 2.625 |

| 435 | 2.188 | 2.688 |

| Dash # | A | B |

|---|---|---|

| 436 | 2.250 | 2.750 |

| 437 | 2.313 | 2.813 |

| 438 | 2.375 | 2.875 |

| 439 | 2.438 | 2.938 |

| 440 | 2.500 | 3.000 |

| 441 | 2.563 | 3.063 |

| 442 | 2.625 | 3.125 |

| 443 | 2.688 | 3.188 |

| 444 | 2.750 | 3.250 |

| 445 | 2.813 | 3.313 |

| 446 | 2.875 | 3.375 |

| 447 | 2.938 | 3.438 |

| 448 | 3.000 | 3.500 |

| 449 | 3.063 | 3.563 |

| 450 | 3.125 | 3.625 |

| 451 | 3.188 | 3.688 |

| 452 | 3.250 | 3.750 |

| 453 | 3.313 | 3.813 |

| 454 | 3.375 | 3.875 |

| 455 | 3.438 | 3.938 |

| 456 | 3.500 | 4.000 |

| 457 | 3.563 | 4.063 |

| 458 | 3.625 | 4.125 |

| 459 | 3.688 | 4.188 |

| 460 | 3.750 | 4.250 |

| 461 | 3.813 | 4.313 |

| 462 | 3.875 | 4.375 |

| 463 | 3.938 | 4.438 |

| 464 | 4.000 | 4.500 |

| 465 | 4.063 | 4.563 |

| 466 | 4.125 | 4.625 |

Consult Eclipse Engineering for all custom or unlisted sizes.

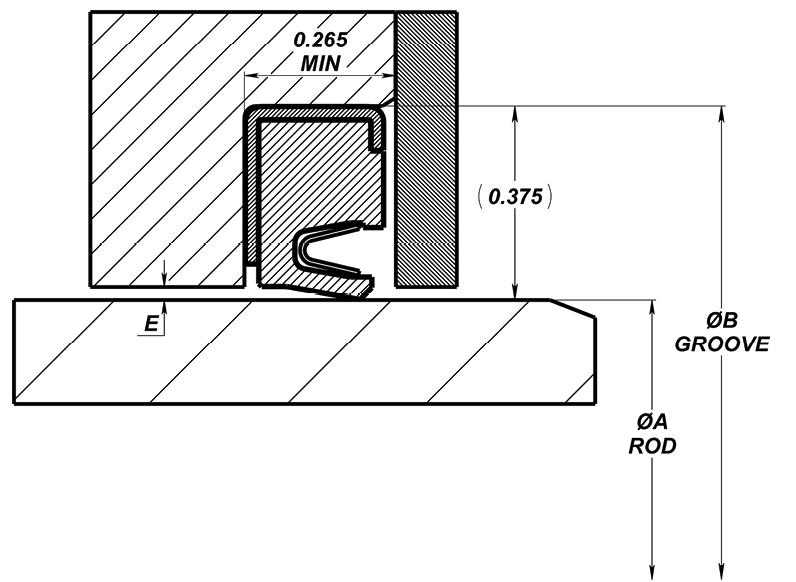

500 SERIES STANDARD DASH NUMBERS

| Gland tolerances | ||

|---|---|---|

| SEAL ID | ØA | ØB |

| 0.125 to 0.374 | +0.000

-0.001 |

± 0.001 |

| 0.375 to 2.999 | +0.000

-0.002 |

± 0.001 |

| 3.000 to 5.999 | +0.000

-0.003 |

± 0.0015 |

| 6.000 and up | +0.000

-0.004 |

± 0.002 |

| 500 Series Maximum Extrusion Gap (E), at 70° F | ||

|---|---|---|

| 300 psi | 1500 psi | 3000 psi |

| 0.014 | 0.008 | 0.006 |

500 SERIES STANDARD DASH NUMBERS:

| DASH # | A | B |

|---|---|---|

| 508 | 0.500 | 1.125 |

| 510 | 0.625 | 1.250 |

| 512 | 0.750 | 1.375 |

| 514 | 0.875 | 1.500 |

| 516 | 1.000 | 1.625 |

| 518 | 1.125 | 1.750 |

| 520 | 1.250 | 1.875 |

| 522 | 1.375 | 2.000 |

| 524 | 1.500 | 2.125 |

| 526 | 1.625 | 2.250 |

| 528 | 1.750 | 2.375 |

| 530 | 1.875 | 2.500 |

| 532 | 2.000 | 2.625 |

| 534 | 2.125 | 2.750 |

| 536 | 2.250 | 2.875 |

| 538 | 2.375 | 3.000 |

| 540 | 2.500 | 3.125 |

| 542 | 2.625 | 3.250 |

| 544 | 2.750 | 3.375 |

| 546 | 2.875 | 3.500 |

| 548 | 3.000 | 3.625 |

| 550 | 3.125 | 3.750 |

| 552 | 3.250 | 3.875 |

| 554 | 3.375 | 4.000 |

| 556 | 3.500 | 4.125 |

| 558 | 3.625 | 4.250 |

| 560 | 3.750 | 4.375 |

| 562 | 3.875 | 4.500 |

| 564 | 4.000 | 4.625 |

Consult Eclipse Engineering for all custom or unlisted sizes.

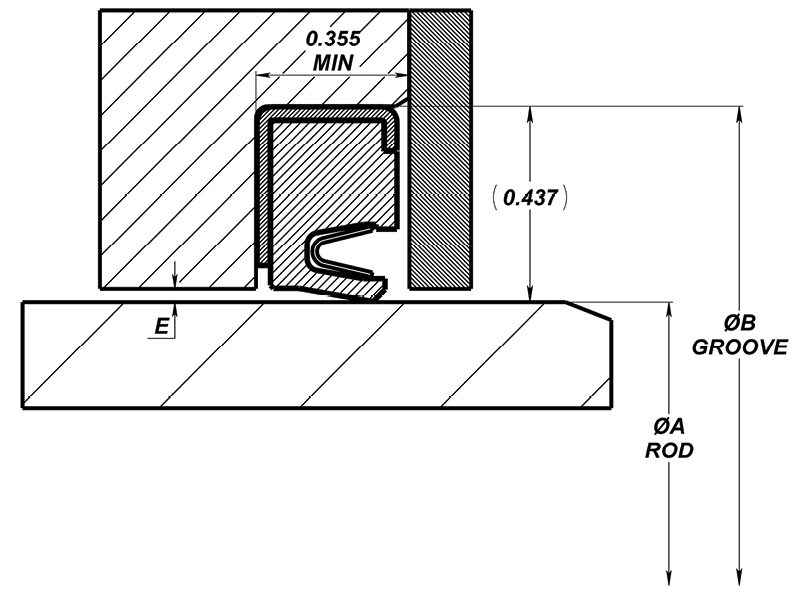

600 SERIES STANDARD DASH NUMBERS

| Gland tolerances | ||

|---|---|---|

| SEAL ID | ØA | ØB |

| 0.125 to 0.374 | +0.000

-0.001 |

± 0.001 |

| 0.375 to 2.999 | +0.000

-0.002 |

± 0.001 |

| 3.000 to 5.999 | +0.000

-0.003 |

± 0.0015 |

| 6.000 and up | +0.000

-0.004 |

± 0.002 |

| 600 Series Maximum Extrusion Gap (E), at 70° F | ||

|---|---|---|

| 300 psi | 1500 psi | 3000 psi |

| 0.014 | 0.008 | 0.006 |

600 SERIES STANDARD DASH NUMBERS:

| DASH # | A | B |

|---|---|---|

| 608 | 0.500 | 1.250 |

| 610 | 0.625 | 1.375 |

| 612 | 0.750 | 1.500 |

| 614 | 0.875 | 1.625 |

| 616 | 1.000 | 1.750 |

| 618 | 1.125 | 1.875 |

| 620 | 1.250 | 2.000 |

| 622 | 1.375 | 2.125 |

| 624 | 1.500 | 2.250 |

| 626 | 1.625 | 2.375 |

| 628 | 1.750 | 2.500 |

| 630 | 1.875 | 2.625 |

| 632 | 2.000 | 2.750 |

| 634 | 2.125 | 2.875 |

| 636 | 2.250 | 3.000 |

| 638 | 2.375 | 3.125 |

| 640 | 2.500 | 3.250 |

| 642 | 2.625 | 3.375 |

| 644 | 2.750 | 3.500 |

| 646 | 2.875 | 3.625 |

| 648 | 3.000 | 3.750 |

| 650 | 3.125 | 3.875 |

| 652 | 3.250 | 4.000 |

| 654 | 3.375 | 4.125 |

| 656 | 3.500 | 4.250 |

| 658 | 3.625 | 4.375 |

| 660 | 3.750 | 4.500 |

| 662 | 3.875 | 4.625 |

| 664 | 4.000 | 4.750 |

Consult Eclipse Engineering for all custom or unlisted sizes.

700 SERIES STANDARD DASH NUMBERS

| Gland tolerances | ||

|---|---|---|

| SEAL ID | ØA | ØB |

| 0.125 to 0.374 | +0.000

-0.001 |

± 0.001 |

| 0.375 to 2.999 | +0.000

-0.002 |

± 0.001 |

| 3.000 to 5.999 | +0.000

-0.003 |

± 0.0015 |

| 6.000 and up | +0.000

-0.004 |

± 0.002 |

| 700 Series Maximum Extrusion Gap (E), at 70° F | ||

|---|---|---|

| 300 psi | 1500 psi | 3000 psi |

| 0.020 | 0.010 | 0.008 |

700 SERIES STANDARD DASH NUMBERS:

| DASH # | A | B |

|---|---|---|

| 712 | 0.750 | 1.625 |

| 714 | 0.875 | 1.750 |

| 716 | 1.000 | 1.875 |

| 718 | 1.125 | 2.000 |

| 720 | 1.250 | 2.125 |

| 722 | 1.375 | 2.250 |

| 724 | 1.500 | 2.375 |

| 726 | 1.625 | 2.500 |

| 728 | 1.750 | 2.625 |

| 730 | 1.875 | 2.750 |

| 732 | 2.000 | 2.875 |

| 734 | 2.125 | 3.000 |

| 736 | 2.250 | 3.125 |

| 738 | 2.375 | 3.250 |

| 740 | 2.500 | 3.375 |

| 742 | 2.625 | 3.500 |

| 744 | 2.750 | 3.625 |

| 746 | 2.875 | 3.750 |

| 748 | 3.000 | 3.875 |

| 750 | 3.125 | 4.000 |

| 752 | 3.250 | 4.125 |

| 754 | 3.375 | 4.250 |

| 756 | 3.500 | 4.375 |

| 758 | 3.625 | 4.500 |

| 760 | 3.750 | 4.625 |

| 762 | 3.875 | 4.750 |

| 764 | 4.000 | 4.875 |

Consult Eclipse Engineering for all custom or unlisted sizes.

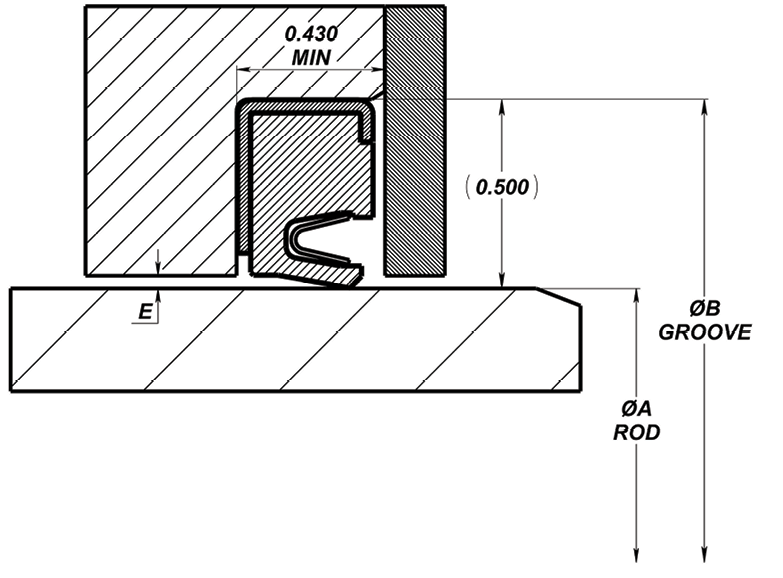

800 SERIES STANDARD DASH NUMBERS

| Gland tolerances | ||

|---|---|---|

| SEAL ID | ØA | ØB |

| 0.125 to 0.374 | +0.000

-0.001 |

± 0.001 |

| 0.375 to 2.999 | +0.000

-0.002 |

± 0.001 |

| 3.000 to 5.999 | +0.000

-0.003 |

± 0.0015 |

| 6.000 and up | +0.000

-0.004 |

± 0.002 |

| 800 Series Maximum Extrusion Gap (E), at 70° F | ||

|---|---|---|

| 300 psi | 1500 psi | 3000 psi |

| 0.024 | 0.012 | 0.010 |

800 SERIES STANDARD DASH NUMBERS:

| DASH # | A | B |

|---|---|---|

| 820 | 1.250 | 2.250 |

| 822 | 1.375 | 2.375 |

| 824 | 1.500 | 2.500 |

| 826 | 1.625 | 2.625 |

| 828 | 1.750 | 2.750 |

| 830 | 1.875 | 2.875 |

| 832 | 2.000 | 3.000 |

| 834 | 2.125 | 3.125 |

| 836 | 2.250 | 3.250 |

| 838 | 2.375 | 3.375 |

| 840 | 2.500 | 3.500 |

| 842 | 2.625 | 3.625 |

| 844 | 2.750 | 3.750 |

| 846 | 2.875 | 3.875 |

| 848 | 3.000 | 4.000 |

| 850 | 3.125 | 4.125 |

| 852 | 3.250 | 4.250 |

| 854 | 3.375 | 4.375 |

| 856 | 3.500 | 4.500 |

| 858 | 3.625 | 4.625 |

| 860 | 3.750 | 4.750 |

| 862 | 3.875 | 4.875 |

| 864 | 4.000 | 5.000 |

Consult Eclipse Engineering for all custom or unlisted sizes.

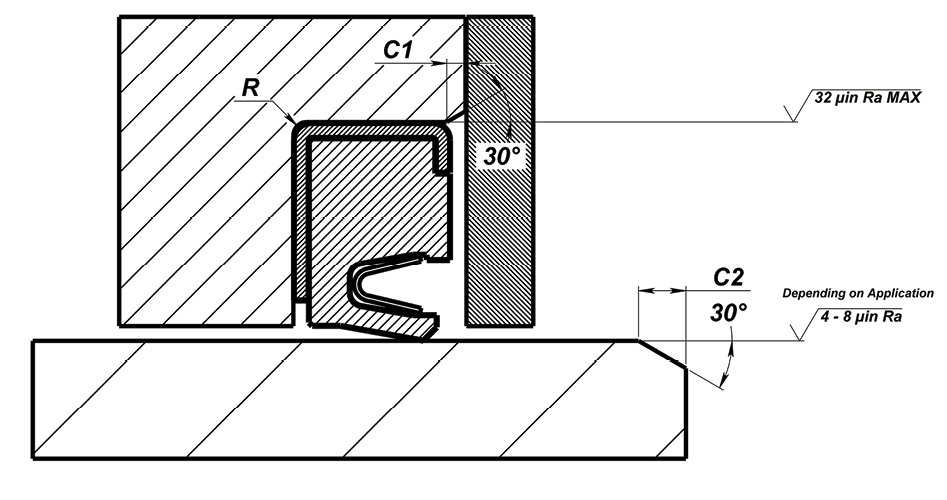

HARDWARE DETAILS – SPLIT GLAND

| Series | R

Radius MAX |

C1

Chamfer MIN |

C2

Chamfer MIN |

|---|---|---|---|

| 000 | 0.010 | 0.010 | 0.031 |

| 100 | 0.015 | 0.015 | 0.050 |

| 200 | 0.015 | 0.015 | 0.062 |

| 300 | 0.015 | 0.020 | 0.093 |

| 400 | 0.020 | 0.020 | 0.125 |

Consult Eclipse Engineering for application/material specific design

requirements or for use in solid or non-standard glands.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!