O-Ring Energized Seals

Eclipse offers a full range of O-Ring Energized seals that can be specified into existing OEM hardware or customized to fit per application.

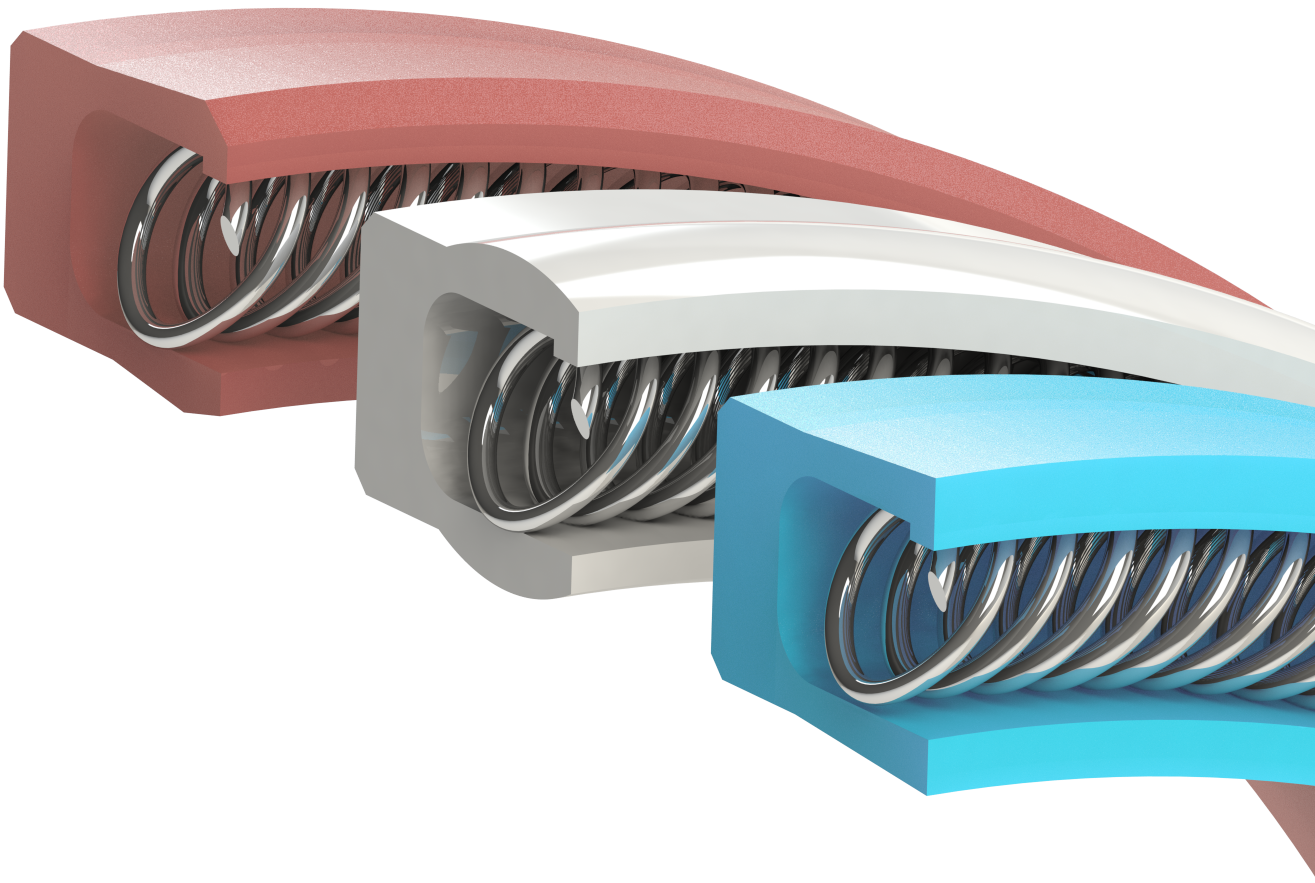

O-Ring energized seals are prevalent in the industry due primarily to their high performance versus cost and their ability to be installed into solid O-Ring style glands in most cases. Commonly specified for use in hydraulic media service in cylinders, valves, unions and transmissions, O-Ring Energized seals cover a broad range of industries from industrial to automotive and aerospace. Eclipse pushes the operating limits of these designs by incorporating an energizer (O-Ring) with the seal element manufactured from ET and EZ class materials. Several configurations exist in order to handle the specific dynamics of a given application.

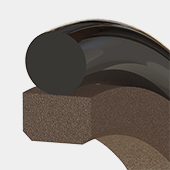

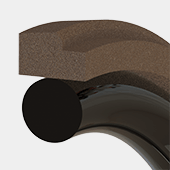

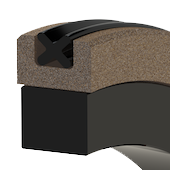

Eclipse O-Ring energized seal rings are a very simple design consisting of a machined seal element energized by an elastomer. Available in rod and piston configurations, Eclipse Seal Rings offer a bi-directional seal solution with a small axial footprint. The seal element is thin enough to be manipulated and installed in a solid groove, but stout enough to ensure long life and pressure performance up to 5,000psi (35MPa). This configuration is especially useful in cylinders requiring smooth, low friction operation. As such, Eclipse Seal Rings should only be considered for reciprocating service.

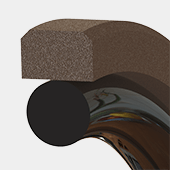

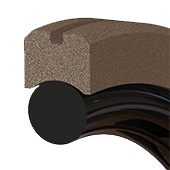

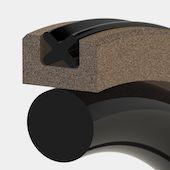

Buffer rings are a support product most often used in conjunction with other seal elements to extend total system life. As the name implies, Buffer Rings are unidirectional seals most often employed at the upstream pressure side of a system and buffer other components from pressure overloads. In service, cylinders can experience external shock loads that cause pressure spikes in excess of system pressure. Due to the asymmetrical design, Eclipse Buffer rings will knock down momentary spikes allowing a small amount of fluid by, which then gets dragged back into the system during the return stroke. Because of this back flow phenomenon, Eclipse buffer rings can also be used in tandem without concern of pressure trapping effects. Available in rod and piston configurations.

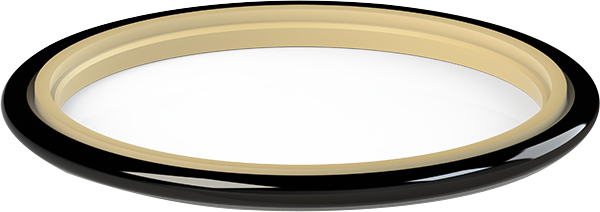

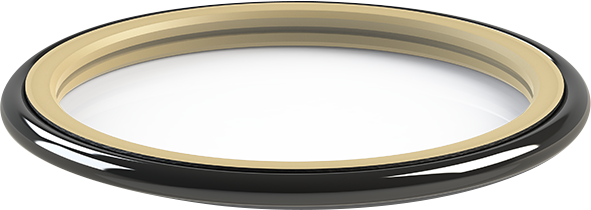

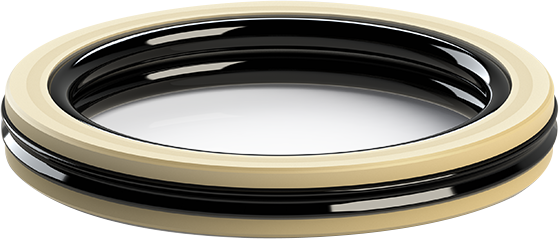

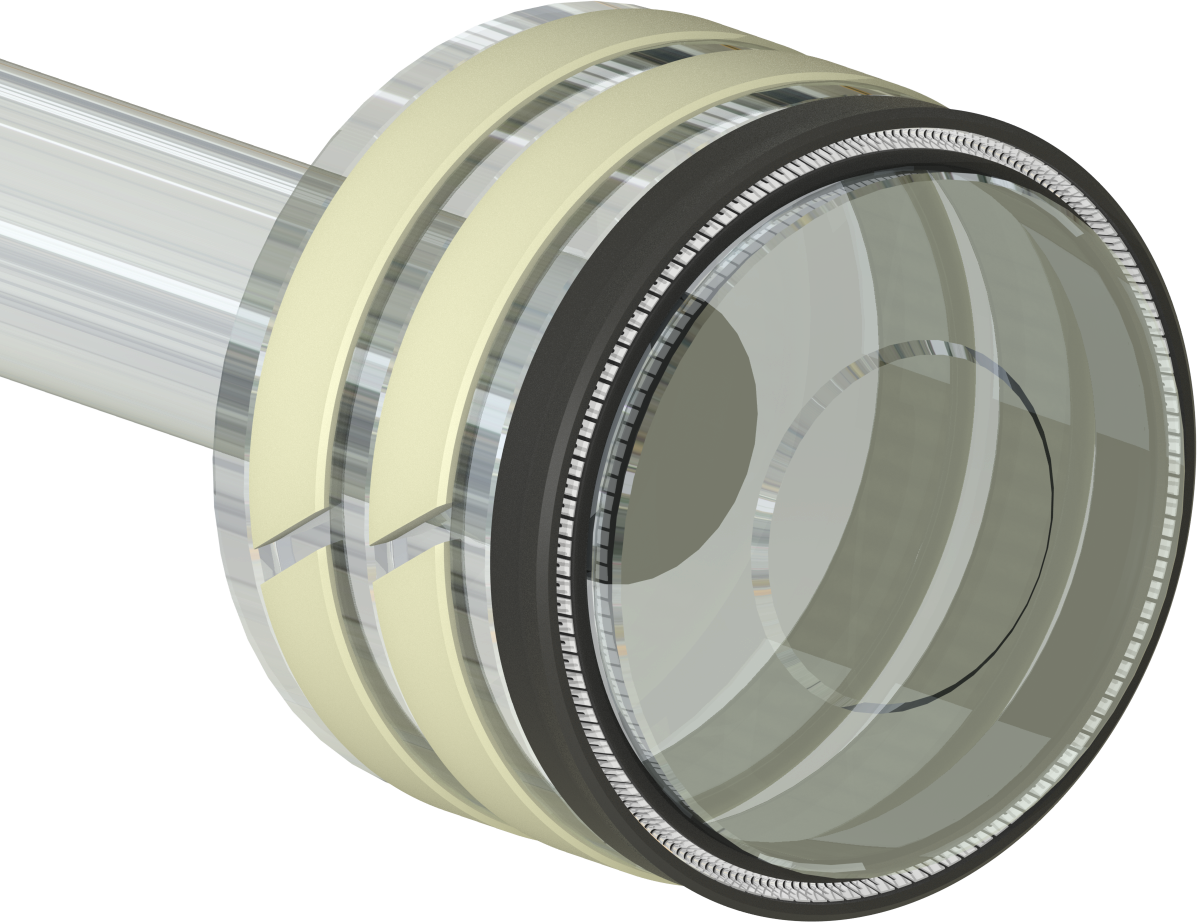

Eclipse Rotary Seal Rings are a bi-directional version of our seal ring modified specifically for low to medium speed rotary and oscillatory applications. The dynamic side of the seal band has geometry designed to hold lubrication and reduce contact pressure while the static side of the band has a high friction coating to mechanically grab the O-Ring energizer and keep the seal stable in the gland. Applications that experience high pressure and low speeds are especially suited for these Rotary Seal Rings. Spool valves, auger mixers, and steering units are typical assemblies utilizing this design. Available in rod and piston configurations.

Eclipse Q seals are unique in that they make use of elastomer contact on both the dynamic and static side of the gland. In this design, the PTFE element acts as a carrier for a rubber quad seal on the dynamic side and gets additional sealing energy from O-Ring(s) on the static side. The intent of the dual elastomer contact is to create a barrier capable of keeping two different media types from mixing. Piston accumulators often make us of this type of seal. Available in piston configurations.

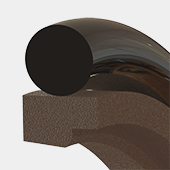

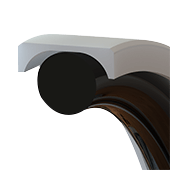

Eclipse Channel seals are thin walled sealing elements, designed to be installed in standard O-Ring glands. The main benefit of using a channel seal is to provide a low friction interface in dynamic applications where stick-slip behavior cannot be tolerated. As thinly machined elements, Channel Seals are easily installed, but should only be specified in moderate duty applications. This design can be employed in shifter mechanisms to keep grease in and exclude contaminants. Channel Seals can also be found in assemblies that must move incrementally with small input forces such as fuel control valves and pneumatic actuators.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!