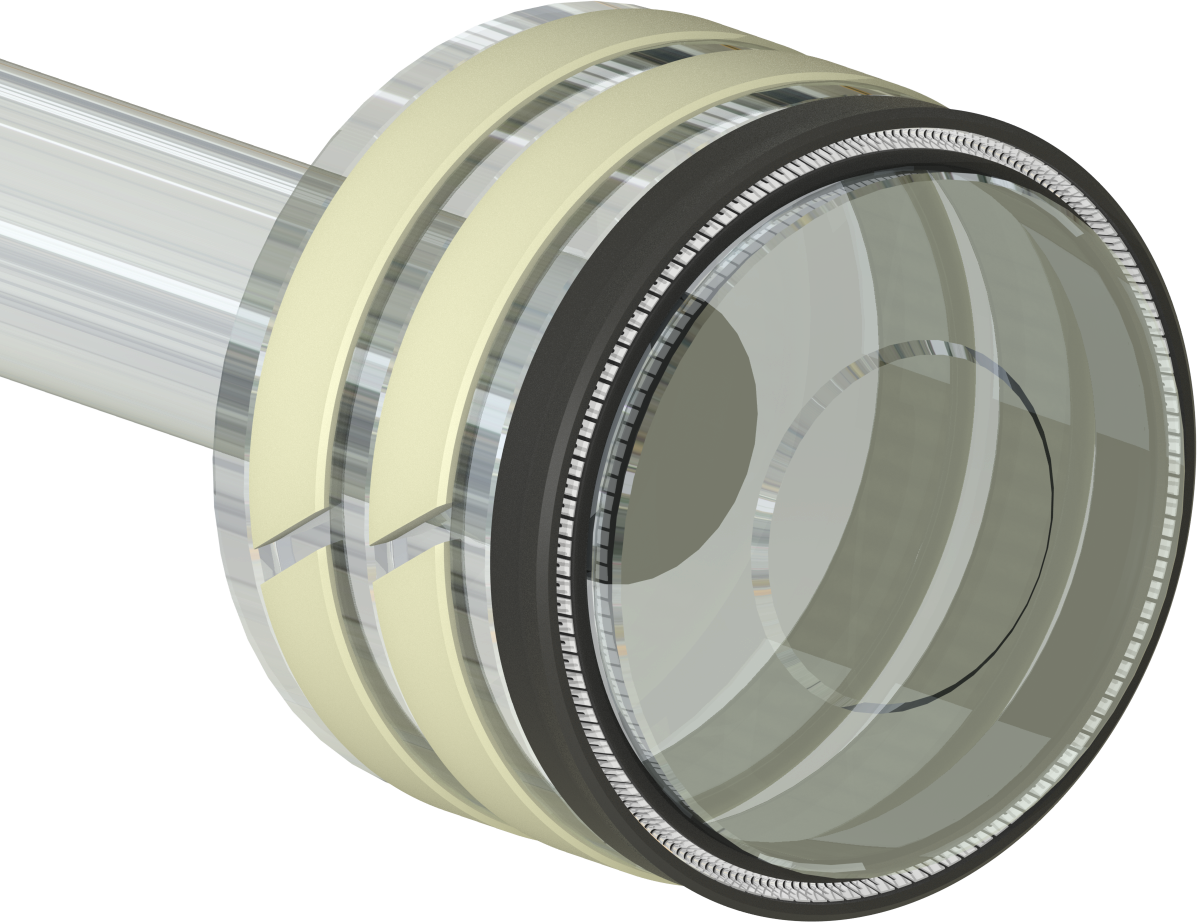

ECLIPSE ESR – PISTON SEAL

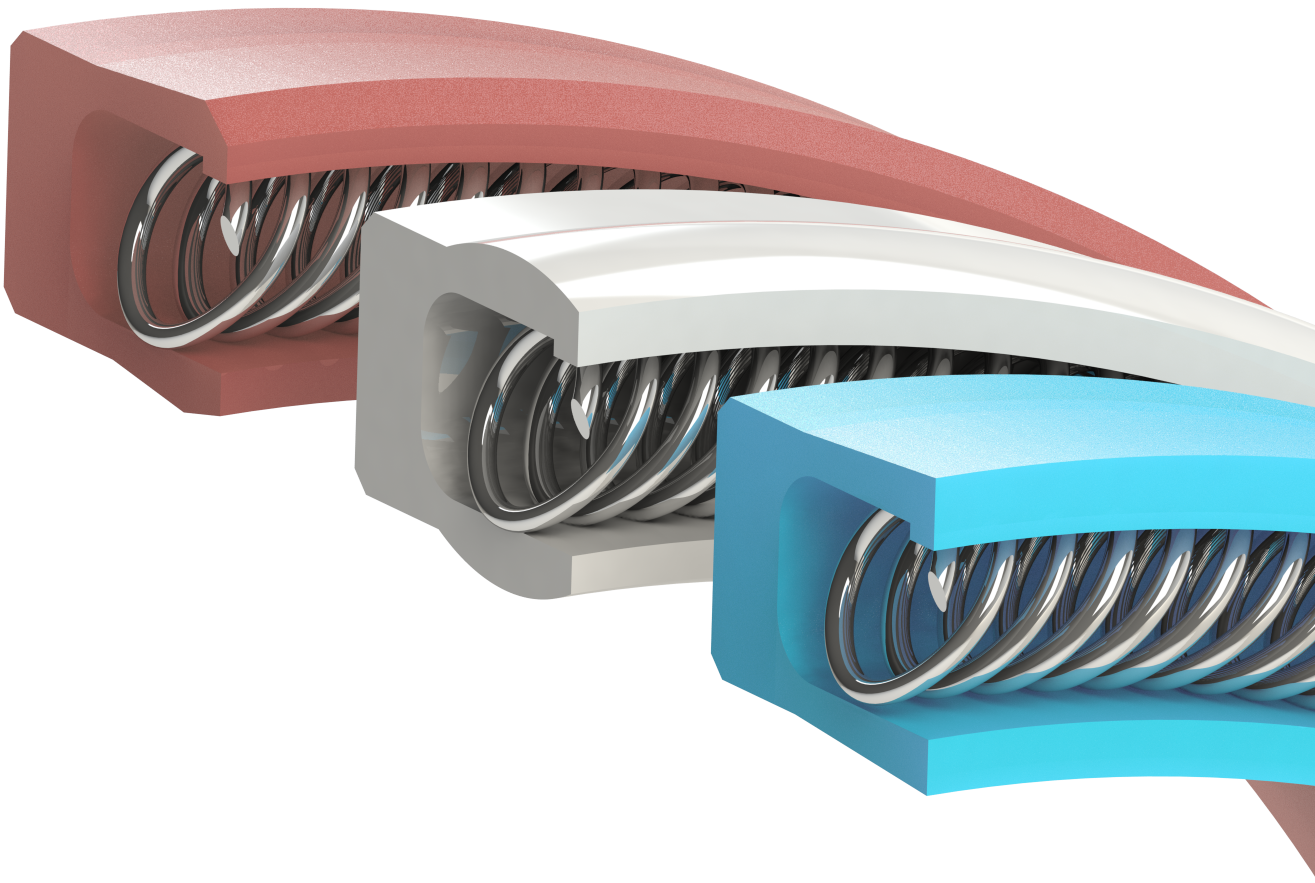

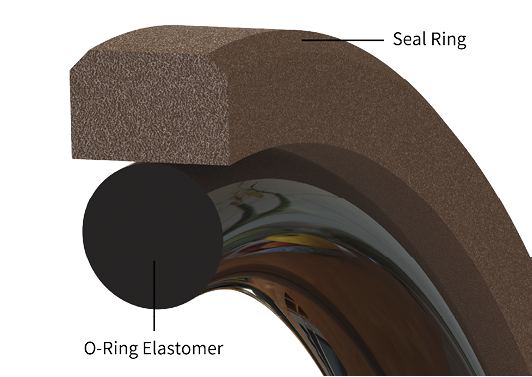

ESR Piston seals are linear, bi-directional, elastomer energized seals typically used in reciprocating hydraulic cylinder assemblies but available for a wide variety of industries and applications. Advantages include long wear life, low friction, and simple groove design. The ESR profile will retrofit non-Eclipse seals designed for similar hardware.

Typical Range of Application

Pressure

1,500 – 5,000 psi

[100 – 350 bar]

Temperature*

-30°F to 250°F

[-34°C to 121°C]

Velocity

5 fps [1.5 m/s]

Media

Hydraulic/ Mineral Oil, Gases, Water

*Limited by O-Ring compound

Values and ratings in this catalog are based on industry standard applications operating under ideal conditions. The customer should assume responsiblity for validation testing of performance and suitabilty of Eclipse Engineering products. Eclipse Engineering accepts no liabilty for the accuracy and applicabilty of provided information.

ORDERING EXAMPLE:

ESR2-P-03000-ET010-N

| ESR2 | = Seal Ring Series |

| P | = Piston |

| 03000 | = Rod Diameter X 1000 (inches) |

| ET010 | = Material Code |

| N | = O-Ring Material Code |

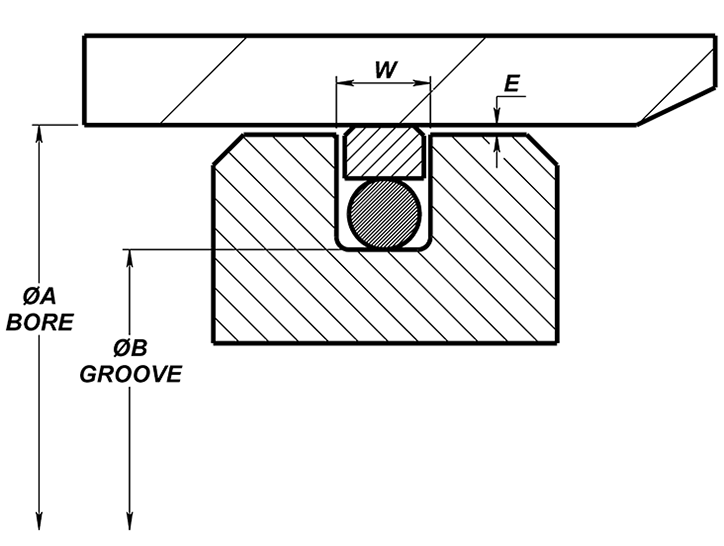

| CROSS

SECTION SERIES |

ØA

BORE H9 |

ØB

GROOVE h9 |

GROOVE WIDTH

+0.008/ -0.000 |

E CLEARANCE (MAX) | ||

|---|---|---|---|---|---|---|

| 1500 PSI | 3000 PSI | 5000 PSI | ||||

| ESR0 | 0.375 – 0.563 | ØA – 0.193 | 0.087 | 0.020 | 0.012 | 0.008 |

| ESR1 | 0.563 – 1.563 | ØA – 0.295 | 0.126 | 0.024 | 0.016 | 0.008 |

| ESR2 | 1.563 – 3.125 | ØA – 0.433 | 0.165 | 0.024 | 0.016 | 0.008 |

| ESR3 | 3.125 – 5.250 | ØA – 0.610 | 0.248 | 0.031 | 0.020 | 0.012 |

| ESR4 | 5.250 – 12.500 | ØA – 0.827 | 0.319 | 0.031 | 0.020 | 0.012 |

| ESR5 | 12.500 – 26.000 | ØA – 0.965 | 0.319 | 0.035 | 0.020 | 0.016 |

ESR STANDARD SEAL MATERIALS

| ECLIPSE MATERIAL CODE | DESCRIPTION | COLOR | APPLICATIONS |

|---|---|---|---|

| ET010 | Bronze filled PTFE | Brown | Standard material for hydraulics |

| ET020 | Carbon Fiber filled PTFE | Black | Abrasive, heavy wear, extended life requirements |

| ET014 | Polyimide filled PTFE | Orange/Brown | High sealabilty, soft hardware |

See Eclipse Material Guide for complete list of available materials.

O-RING MATERIALS

| ECLIPSE MATERIAL CODE | DESCRIPTION | HARDNESS SHORE A | TEMPERATURE RANGE |

|---|---|---|---|

| 0 or blank | Seal provided without O-Ring | – | – |

| N | Nitrile (NBR) | 70 | -30°F to 250°F [-34°C to 121°C] |

| F | Fluorocarbon (FKM) | 75 | -15°F to 400°F [-26°C to 205°C] |

| E | Ethylene Propylene (EPDM) | 70 | -70°F to 250°F [-57°C to 121°C] |

Full range of elastomer compounds available for specialty applications.

STANDARD PART NUMBERS

000 SERIES:

| PART NUMBER | BORE Ø

+0.002/-0.000 |

GROOVE Ø

+0.000/-0.002 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR0-P-00375 | 0.375 | 0.182 | 0.087/0.095 | 2-008 |

| ESR0-P-00394 | 0.394 (10MM) | 0.201 | 2-008 | |

| ESR0-P-00438 | 0.438 | 0.245 | 2-010 | |

| ESR0-P-00472 | 0.472 (12MM) | 0.279 | 2-010 | |

| ESR0-P-00500 | 0.500 | 0.307 | 2-011 | |

| ESR0-P-00551 | 0.551 (14MM) | 0.358 | 2-011 | |

| ESR0-P-00563 | 0.563 | 0.370 | 2-012 |

Consult Eclipse Engineering for all custom or unlisted sizes.

100 SERIES:

| PART NUMBER | BORE Ø

+0.002/-0.000 |

GROOVE Ø

+0.000/-0.002 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR1-P-00625 | 0.625 | 0.330 | 0.126/0.134 | 2-109 |

| ESR1-P-00750 | 0.750 | 0.455 | 2-111 | |

| ESR1-P-00787 | 0.787 (20MM) | 0.492 | 2-112 | |

| ESR1-P-00875 | 0.875 | 0.580 | 2-113 | |

| ESR1-P-00938 | 0.938 | 0.643 | 2-114 | |

| ESR1-P-00984 | 0.984 (25MM) | 0.689 | 2-115 | |

| ESR1-P-01000 | 1.000 | 0.705 | 2-115 | |

| ESR1-P-01063 | 1.063 | 0.768 | 2-116 | |

| ESR1-P-01125 | 1.125 | 0.830 | 2-117 | |

| ESR1-P-01181 | 1.181 (30MM) | 0.886 | 2-118 | |

| ESR1-P-01188 | 1.188 | 0.893 | 2-118 | |

| ESR1-P-01250 | 1.250 | 0.955 | 2-119 |

| PART NUMBER | BORE Ø

+0.002/-0.000 |

GROOVE Ø

+0.000/-0.002 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR1-P-01313 | 1.313 | 1.018 | 0.126/0.134 | 2-120 |

| ESR1-P-01375 | 1.375 | 1.080 | 2-121 | |

| ESR1-P-01378 | 1.378 (35MM) | 1.083 | 2-121 | |

| ESR1-P-01438 | 1.438 | 1.143 | 2-122 | |

| ESR1-P-01500 | 1.500 | 1.205 | 2-123 | |

| ESR1-P-01563 | 1.563 | 1.268 | 2-124 |

Consult Eclipse Engineering for all custom or unlisted sizes.

200 SERIES:

| PART NUMBER | BORE Ø

+0.003/-0.000 |

GROOVE Ø

+0.000/-0.003 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR2-P-01625 | 1.625 | 1.192 | 0.165/0.173 | 2-217 |

| ESR2-P-01688 | 1.688 | 1.255 | 2-218 | |

| ESR2-P-01750 | 1.750 | 1.317 | 2-219 | |

| ESR2-P-01772 | 1.772 (45MM) | 1.339 | 2-219 | |

| ESR2-P-01875 | 1.875 | 1.442 | 2-221 | |

| ESR2-P-01938 | 1.938 | 1.505 | 2-222 | |

| ESR2-P-01968 | 1.968 (50MM) | 1.535 | 2-222 | |

| ESR2-P-02000 | 2.000 | 1.567 | 2-222 | |

| ESR2-P-02125 | 2.125 | 1.692 | 2-223 | |

| ESR2-P-02165 | 2.165 (55MM) | 1.732 | 2-224 | |

| ESR2-P-02250 | 2.250 | 1.817 | 2-224 | |

| ESR2-P-02362 | 2.362 (60MM) | 1.929 | 2-225 | |

| ESR2-P-02375 | 2.375 | 1.942 | 2-225 | |

| ESR2-P-02500 | 2.500 | 2.067 | 2-226 | |

| ESR2-P-02559 | 2.559 (65MM) | 2.126 | 2-227 |

| PART NUMBER | BORE Ø

+0.003/-0.000 |

GROOVE Ø

+0.000/-0.003 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR2-P-02625 | 2.625 | 2.192 | 0.165/0.173 | 2-227 |

| ESR2-P-02750 | 2.750 | 2.317 | 2-228 | |

| ESR2-P-02756 | 2.756 (70MM) | 2.323 | 2-228 | |

| ESR2-P-02875 | 2.875 | 2.442 | 2-229 | |

| ESR2-P-02953 | 2.953 (75MM) | 2.520 | 2-230 | |

| ESR2-P-03000 | 3.000 | 2.567 | 2-230 | |

| ESR2-P-03125 | 3.125 | 2.692 | 2-231 |

Consult Eclipse Engineering for all custom or unlisted sizes.

300 SERIES:

| PART NUMBER | BORE Ø

+0.003/-0.000 |

GROOVE Ø

+0.000/-0.003 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR3-P-03250 | 3.250 | 2.640 | 0.248/0.256 | 2-334 |

| ESR3-P-03346 | 3.346 (85MM) | 2.736 | 2-335 | |

| ESR3-P-03375 | 3.375 | 2.765 | 2-335 | |

| ESR3-P-03500 | 3.500 | 2.890 | 2-336 | |

| ESR3-P-03543 | 3.543 (90MM) | 2.933 | 2-336 | |

| ESR3-P-03625 | 3.625 | 3.015 | 2-337 | |

| ESR3-P-03740 | 3.740 (95MM) | 3.130 | 2-338 | |

| ESR3-P-03750 | 3.750 | 3.140 | 2-338 | |

| ESR3-P-03875 | 3.875 | 3.265 | 2-339 | |

| ESR3-P-03937 | 3.937 (100MM) | 3.327 | 2-339 | |

| ESR3-P-04000 | 4.000 | 3.390 | 2-340 | |

| ESR3-P-04125 | 4.125 | 3.515 | 2-341 | |

| ESR3-P-04134 | 4.134 (105MM) | 3.524 | 2-341 | |

| ESR3-P-04250 | 4.250 | 3.640 | 2-342 | |

| ESR3-P-04331 | 4.331 (110MM) | 3.721 | 2-343 |

| PART NUMBER | BORE Ø

+0.003/-0.000 |

GROOVE Ø

+0.000/-0.003 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR3-P-04375 | 4.375 | 3.765 | 0.248/0.256 | 2-343 |

| ESR3-P-04500 | 4.500 | 3.890 | 2-344 | |

| ESR3-P-04528 | 4.528 (115MM) | 3.918 | 2-344 | |

| ESR3-P-04625 | 4.625 | 4.015 | 2-345 | |

| ESR3-P-04724 | 4.724 (120MM) | 4.114 | 2-346 | |

| ESR3-P-04750 | 4.750 | 4.140 | 2-346 | |

| ESR3-P-05000 | 5.000 | 4.390 | 2-348 | |

| ESR3-P-05250 | 5.250 | 4.640 | 2-350 |

Consult Eclipse Engineering for all custom or unlisted sizes.

400 SERIES:

| PART NUMBER | BORE Ø

+0.004/-0.000 |

GROOVE Ø

+0.000/-0.005 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR4-P-05375 | 5.375 | 4.548 | 0.319/0.327 | 2-425 |

| ESR4-P-05500 | 5.500 | 4.673 | 2-426 | |

| ESR4-P-05512 | 5.512 (140MM) | 4.685 | 2-426 | |

| ESR4-P-05625 | 5.625 | 4.798 | 2-427 | |

| ESR4-P-05750 | 5.750 | 4.923 | 2-428 | |

| ESR4-P-05906 | 5.906 (150mm) | 5.079 | 2-429 | |

| ESR4-P-06000 | 6.000 | 5.173 | 2-430 | |

| ESR4-P-06250 | 6.250 | 5.423 | 2-432 | |

| ESR4-P-06299 | 6.299 (160MM) | 5.472 | 2-433 | |

| ESR4-P-06500 | 6.500 | 5.673 | 2-434 | |

| ESR4-P-06693 | 6.693 (170MM) | 5.866 | 2-436 | |

| ESR4-P-06750 | 6.750 | 5.923 | 2-436 | |

| ESR4-P-07000 | 7.000 | 6.173 | 2-437 | |

| ESR4-P-07087 | 7.087 (180MM) | 6.260 | 2-438 | |

| ESR4-P-07250 | 7.250 | 6.423 | 2-438 |

| PART NUMBER | BORE Ø

+0.004/-0.000 |

GROOVE Ø

+0.000/-0.005 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR4-P-07480 | 7.480 (190MM) | 6.653 | 0.319/0.327 | 2-439 |

| ESR4-P-07500 | 7.500 | 6.673 | 2-439 | |

| ESR4-P-07750 | 7.750 | 6.923 | 2-440 | |

| ESR4-P-07874 | 7.874 (200MM) | 7.047 | 2-441 | |

| ESR4-P-08000 | 8.000 | 7.173 | 2-441 | |

| ESR4-P-08250 | 8.250 | 7.423 | 2-442 | |

| ESR4-P-08268 | 8.268 (210MM) | 7.441 | 2-442 | |

| ESR4-P-08500 | 8.500 | 7.673 | 2-443 | |

| ESR4-P-08661 | 8.661 (220MM) | 7.834 | 2-444 | |

| ESR4-P-08750 | 8.750 | 7.923 | 2-444 | |

| ESR4-P-09000 | 9.000 | 8.173 | 2-445 | |

| ESR4-P-09250 | 9.250 | 8.423 | 2-445 | |

| ESR4-P-09252 | 9.252 (235MM) | 8.425 | 2-445 | |

| ESR4-P-09500 | 9.500 | 8.673 | 2-446 | |

| ESR4-P-09750 | 9.750 | 8.923 | 2-446 |

Consult Eclipse Engineering for all custom or unlisted sizes.

400 SERIES CONTINUED:

| PART NUMBER | BORE Ø

+0.004/-0.000 |

GROOVE Ø

+0.000/-0.005 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR4-P-09843 | 9.843 (250MM) | 9.016 | 0.319/0.327 | 2-447 |

| ESR4-P-10000 | 10.000 | 9.173 | 2-447 | |

| ESR4-P-10433 | 10.433 (265MM) | 9.606 | 2-448 | |

| ESR4-P-10500 | 10.500 | 9.673 | 2-448 | |

| ESR4-P-11000 | 11.000 | 10.173 | 2-449 | |

| ESR4-P-11024 | 11.024 (280MM) | 10.197 | 2-449 | |

| ESR4-P-11500 | 11.500 | 10.673 | 2-450 | |

| ESR4-P-11811 | 11.811 (300MM) | 10.984 | 2-451 | |

| ESR4-P-12000 | 12.000 | 11.173 | 2-451 | |

| ESR4-P-12500 | 12.500 | 11.673 | 2-452 |

Consult Eclipse Engineering for all custom or unlisted sizes.

500 SERIES

| PART NUMBER | BORE Ø

+0.006/-0.000 |

GROOVE Ø

+0.000/-0.007 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR5-P-13000 | 13.000 | 12.035 | 0.319/0.327 | 2-453 |

| ESR5-P-13500 | 13.500 | 12.535 | 2-454 | |

| ESR5-P-13780 | 13.780 (350MM) | 12.815 | 2-454 | |

| ESR5-P-14000 | 14.000 | 13.035 | 2-455 | |

| ESR5-P-14500 | 14.500 | 13.535 | 2-456 | |

| ESR5-P-14764 | 14.764 (375MM) | 13.799 | 2-456 | |

| ESR5-P-15000 | 15.000 | 14.035 | 2-457 | |

| ESR5-P-15500 | 15.500 | 14.535 | 2-458 | |

| ESR5-P-15748 | 15.748 (400MM) | 14.783 | 2-458 | |

| ESR5-P-16000 | 16.000 | 15.035 | 2-459 | |

| ESR5-P-16500 | 16.500 | 15.535 | 2-460 | |

| ESR5-P-16732 | 16.732 (425MM) | 15.767 | 2-460 | |

| ESR5-P-17000 | 17.000 | 16.035 | 2-461 | |

| ESR5-P-17500 | 17.500 | 16.535 | 2-462 | |

| ESR5-P-17717 | 17.717 (450MM) | 16.752 | 2-462 |

| PART NUMBER | BORE Ø

+0.006/-0.000 |

GROOVE Ø

+0.000/-0.007 |

GROOVE WIDTH | O-RING

DASH SIZE |

|---|---|---|---|---|

| ESR5-P-18000 | 18.000 | 17.035 | 0.319/0.327 | 2-463 |

| ESR5-P-18500 | 18.500 | 17.535 | 2-464 | |

| ESR5-P-19000 | 19.000 | 18.035 | 2-465 | |

| ESR5-P-19500 | 19.500 | 18.535 | 2-466 | |

| ESR5-P-19685 | 19.685 (500MM) | 18.720 | 2-466 | |

| ESR5-P-20000 | 20.000 | 19.035 | 2-467 |

Consult Eclipse Engineering for all custom or unlisted sizes.

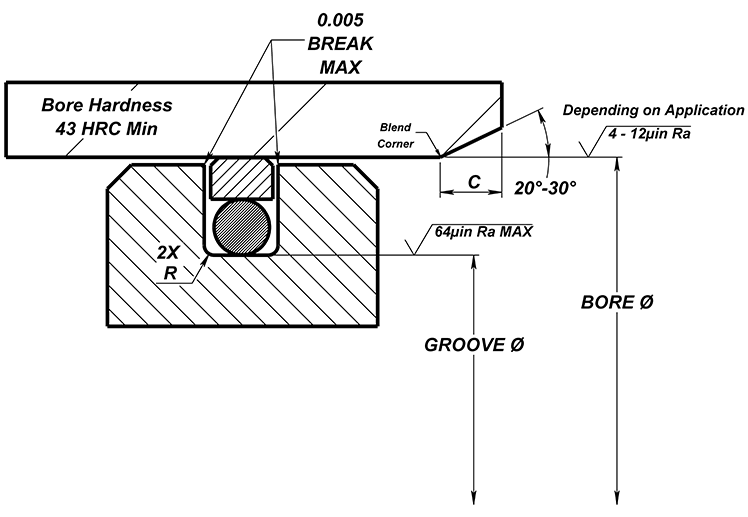

HARDWARE DETAILS

| CROSS SECTION SERIES | MIN BORE Ø FOR SOLID GLAND INSTALLATION | R RADIUS (MAX) | C LEAD-IN CHAMFER (MIN) |

|---|---|---|---|

| ESR0 | 0.375 | 0.015 | 0.080 |

| ESR1 | 0.563 | 0.025 | 0.125 |

| ESR2 | 1.563 | 0.025 | 0.160 |

| ESR3 | 3.125 | 0.035 | 0.250 |

| ESR4 | 5.250 | 0.035 | 0.300 |

| ESR5 | 12.500 | 0.035 | 0.300 |

Consult Eclipse Engineering for application/material specific hardware design requirements.

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!