BLOG

Eclipse Engineering Blog

By Doug

•

03 Oct, 2022

While the average person can probably recognize a rubber O-Ring, knowledge of advanced sealing devices remains a largely obscure field of knowledge. Eclipse is here to be the subject matter experts and guide you to the best sealing solution, but being familiar with some basic seal terminology will aid us in the process. The ability […]

By Doug

•

10 Aug, 2022

Eclipse serves dozens of industries and provides sealing solutions for applications on, off, and below the surface of the planet. Each application has its own set of challenges whether it be manned space flight, surgical medical instruments, or high-volume automotive components. One industry that continually presents Eclipse with challenging sealing conditions is oil and gas. […]

By Doug

•

30 Jun, 2022

PTFE was discovered in the 1930s as an accidental byproduct of chlorofluorocarbon refrigerant production. It’s a synthetic compound consisting wholly of carbon and fluorine — a fluorocarbon. Its many unique properties make it highly attractive as a seal material. It possesses one of the lowest friction coefficients of any known material, is nearly 100% chemically […]

By Doug

•

19 Apr, 2022

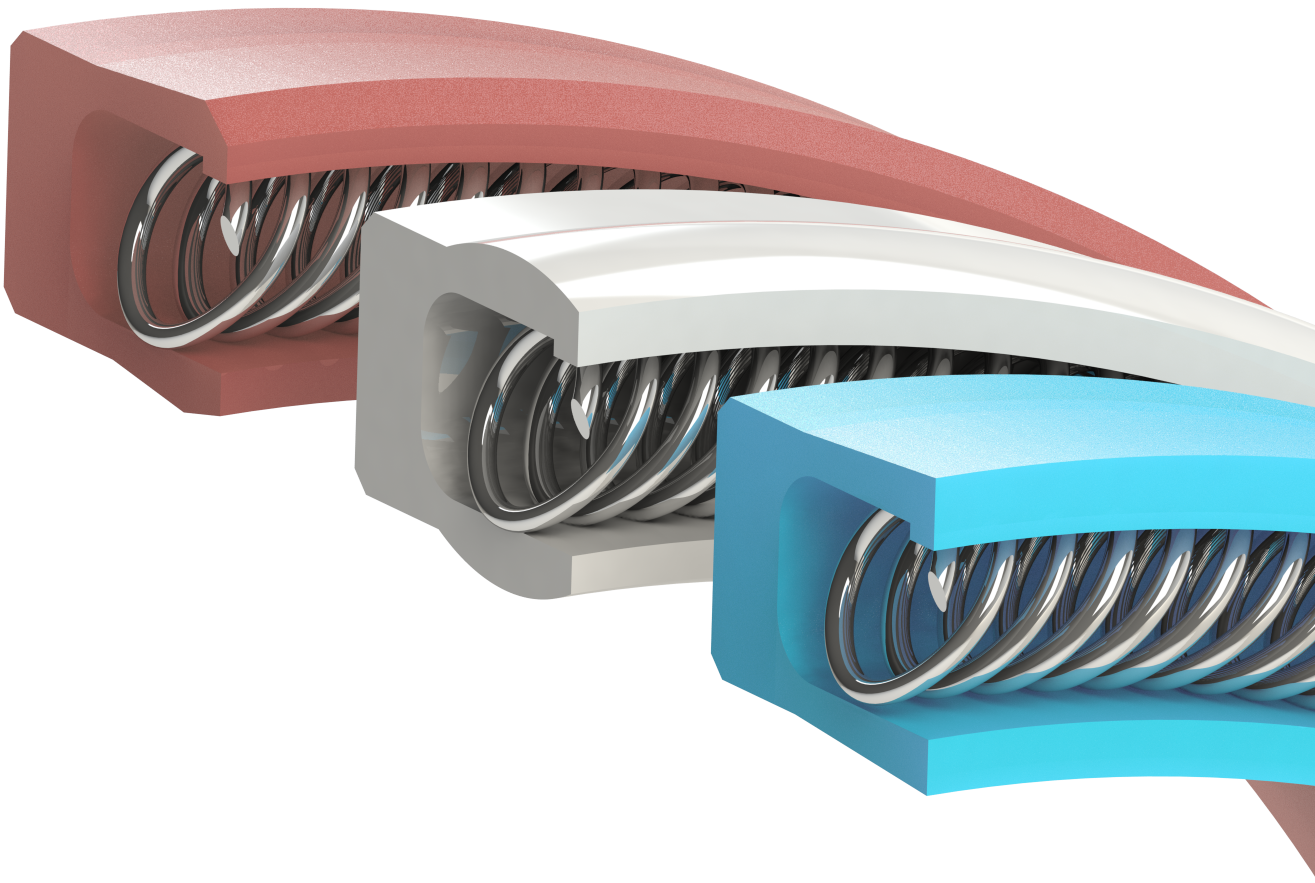

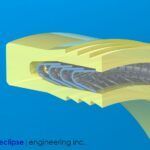

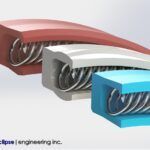

Shortly after the discovery and use of PTFE as a seal material, the need for a secondary energizing method became apparent. Unlike rubber or urethane which possess elastic and spring-like properties, PTFE will not return to its original state once deformed. This is obviously not a desirable trait for sealing material, especially in dynamic sealing […]

By Doug

•

25 Feb, 2022

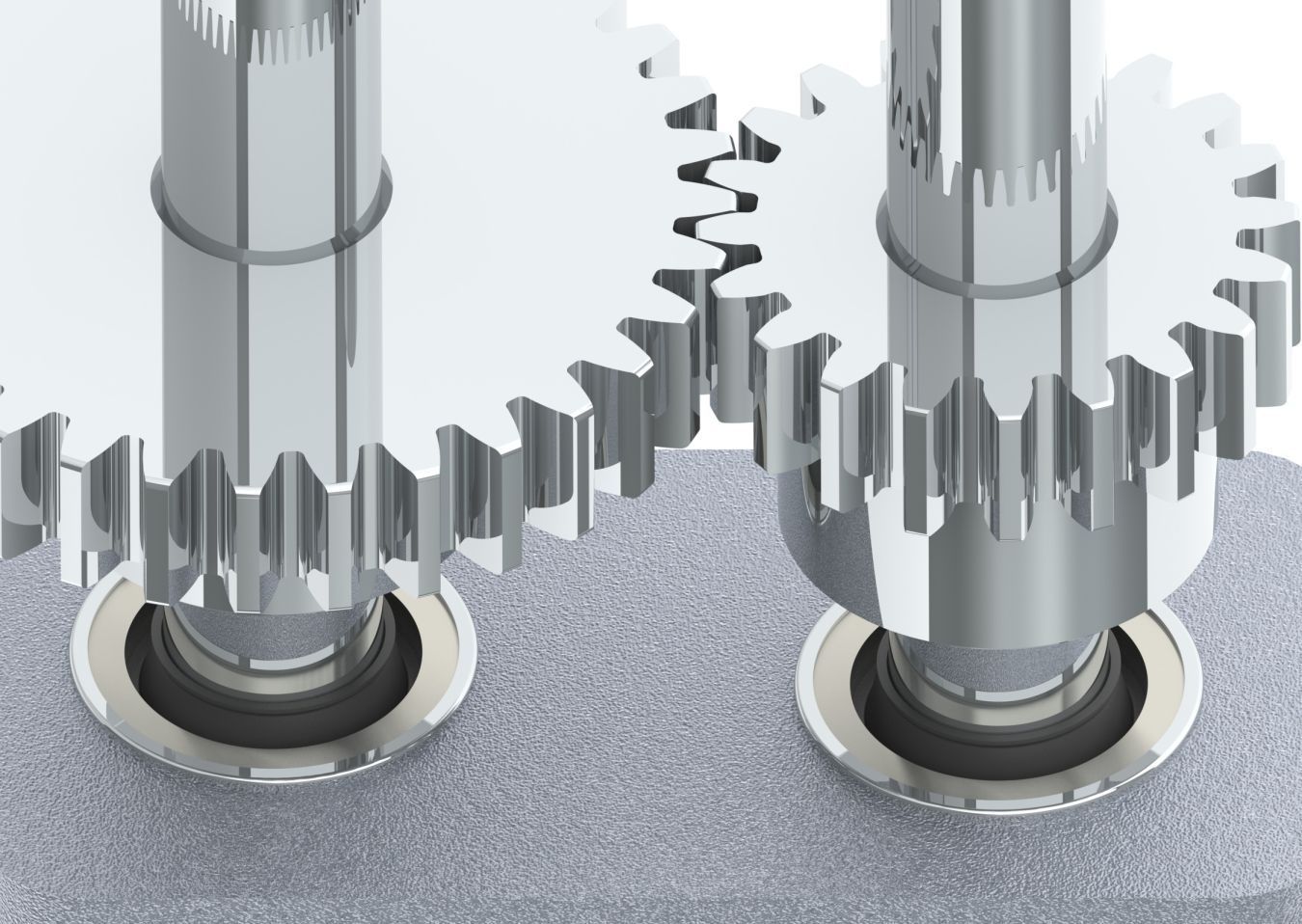

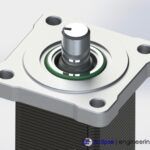

The current global electric motor market is valued at more than 100 billion dollars and is slated for continued growth in the decades to come. It’s estimated that more than 30 million electric motors are produced every year. The increased development of robotics and automation in many industrial processes as well as demand for numerous […]

By Doug

•

28 Jan, 2022

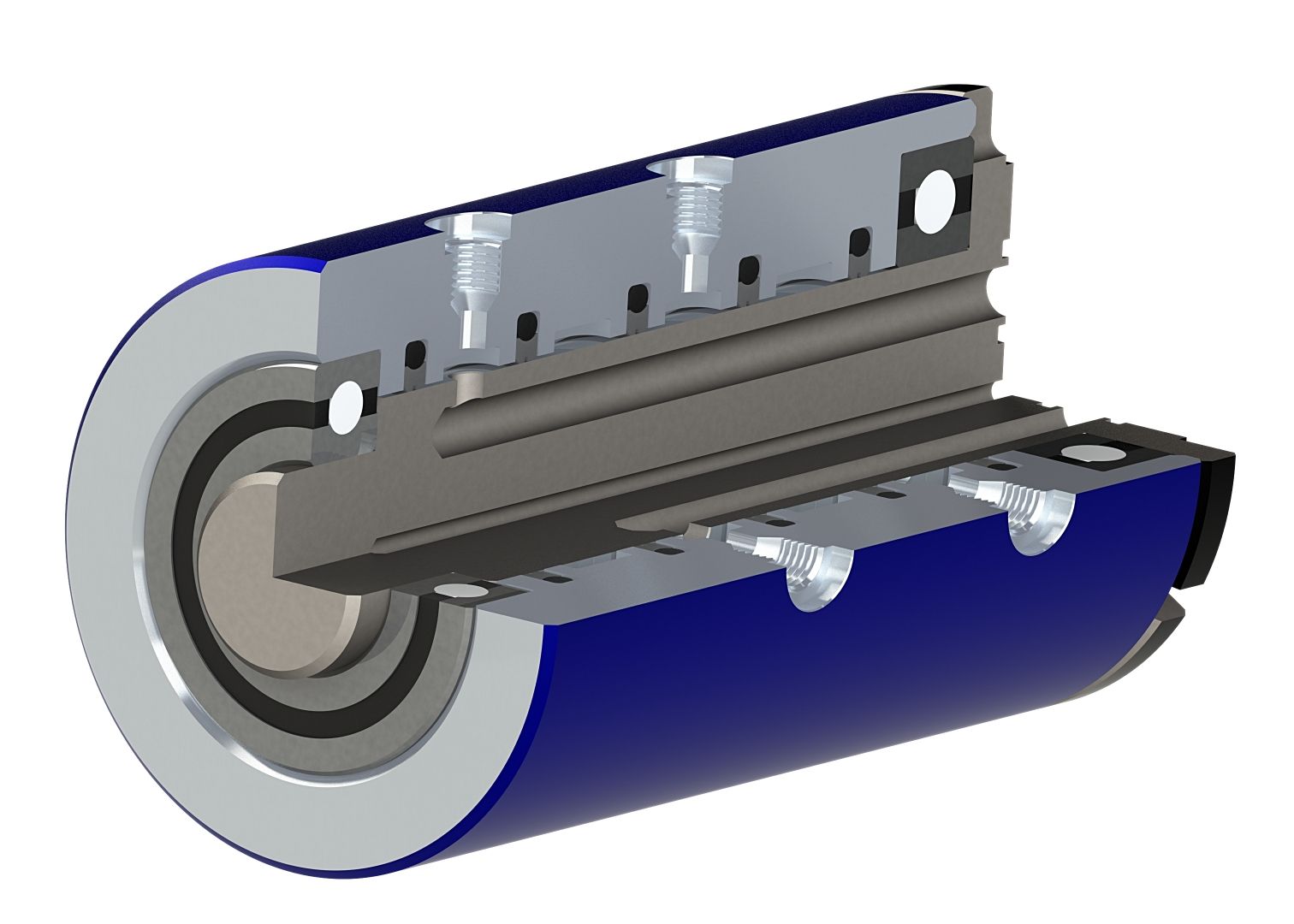

All moving shafts, whether they’re reciprocating or rotary, require some form of guidance to avoid metal-to-metal contact. Relative motion during use will always wear down your appliance. There are many different styles of bearings available in the marketplace today. In some cases, a rotary ball and race are used especially in rotary service due to […]

By Doug

•

27 Dec, 2021

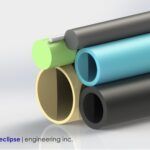

Aside from PTFE and PTFE blends, one of the most used seal materials at Eclipse is UHMW, or Ultra High Molecular Weight Polyethylene. Polyethylene is the most common and prolific plastic in the world today, utilized in everything from consumer-grade packaging to bags, bottles, and medical implants. It’s available in varying densities, such as Low Density (LDPE), High Density (HDPE), and the aforementioned UHMW. The seal world focuses mainly on UHMW employing the […]

By Doug

•

22 Nov, 2021

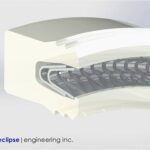

Spring Energized Polymer Seals and O-Rings are very different products, yet they can ultimately accomplish the same goal of sealing a system. The humble O-Ring is, in simplest terms, a ring of rubber. A Spring Energized Seal consists of an engineered plastic jacket, usually a PTFE blend or UHMW-PE, and a metallic spring element. One is made in quantities of […]

By Doug

•

21 Oct, 2021

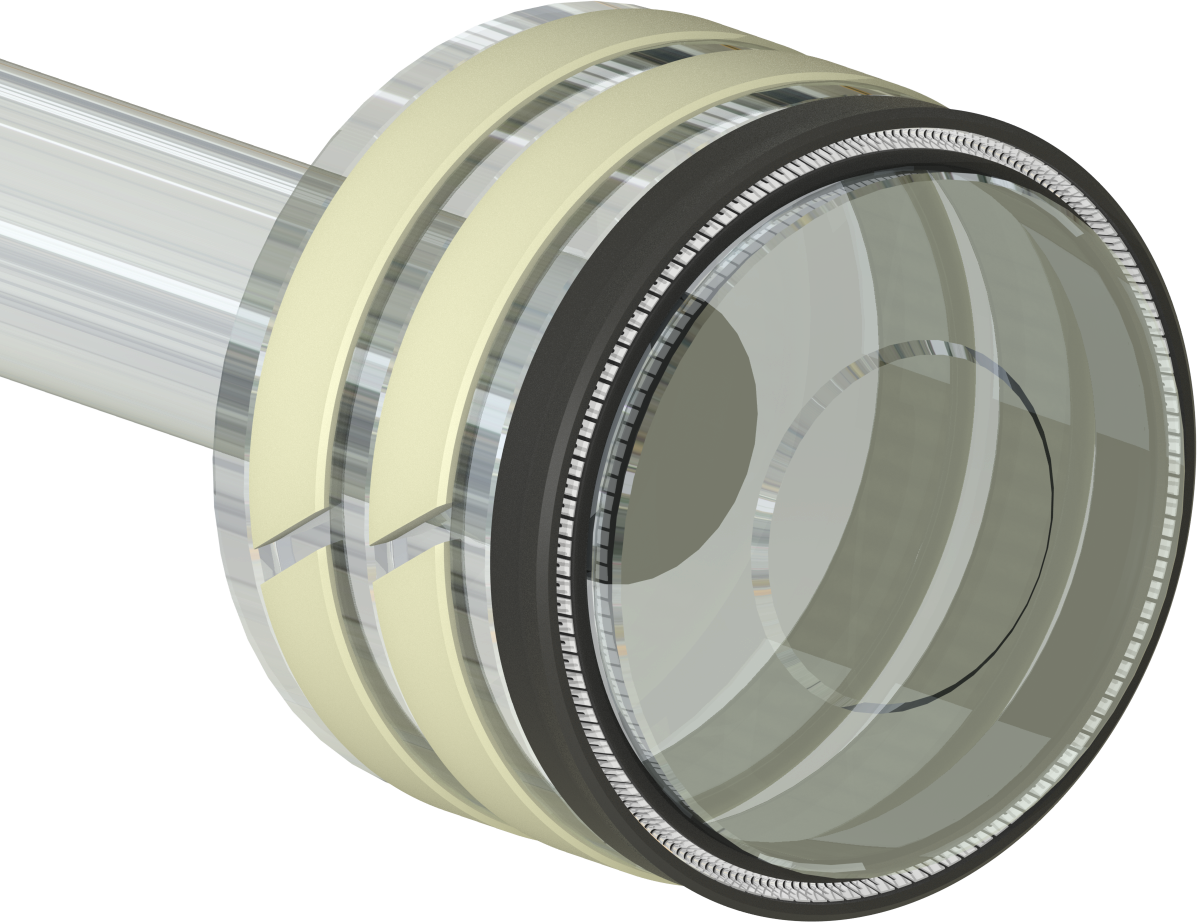

While seal performance, leakage control, and wear-life characteristics are frequently discussed, one critical aspect of a successful sealing system is often overlooked — how a seal is contained in the hardware. Whether you want to call it a gland or a groove, the physical space for housing a seal is an important part of the system’s performance. […]

By Doug

•

17 Sep, 2021

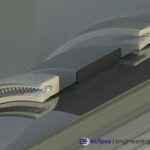

Spring Energized Seals can be found in all kinds of applications across the spectrum of industries and sectors. While the pros and cons of the different spring types contained in the seal are often discussed, the style of sealing lips can also have a significant impact on performance. Every spring type has at least 4 […]

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!