Modified PTFE | EZ

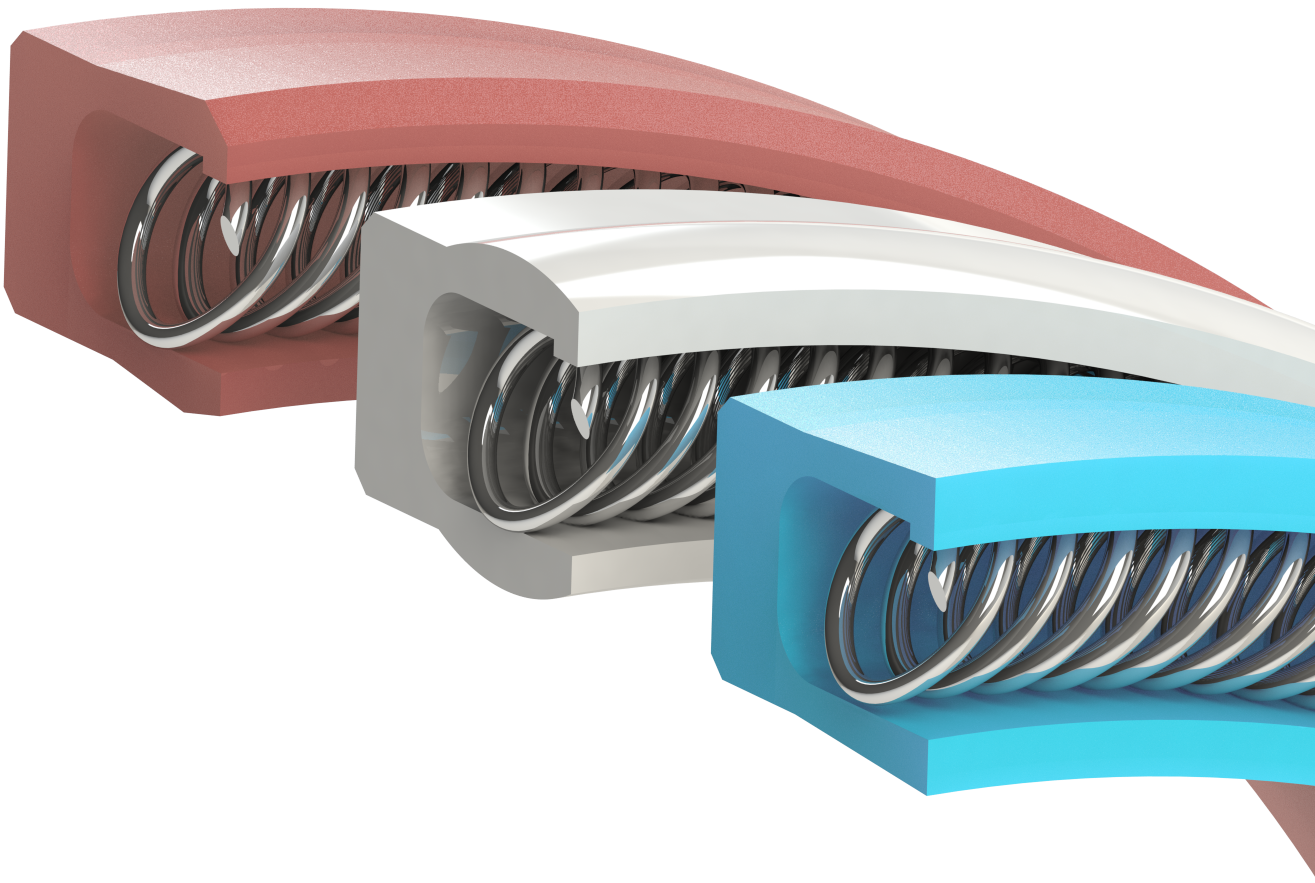

Through the ongoing efforts of Eclipse materials research, a separate class of high performance fluoropolymer blends have been developed. Eclipse EZ materials are based on a modified PTFE resin which exhibits improved compressive strength, wear performance and permeation resistance. As a result, Eclipse EZ materials are able to push the limits in demanding applications. Eclipse EZ materials have been accepted for use in industries ranging from UL approved industrial, to aerospace as well as FDA. Filled versions of Eclipse EZ offer increased creep resistance over filled PTFE compounds, lending them to be used in valve seats and high pressure valves. Like base PTFE, Eclipse EZ offers the same benefits of broad chemical compatibility, low friction and service temperatures from cryogenic to nearly 600°F (316°C).

Available Materials

Modified PTFE, 100% Virgin – General purpose unfilled Modified PTFE for gains listed above. Fantastic selection for cryogenic applications.

Modified PTFE, 15% Glass Filled – For applications requiring higher compressive strength and rigidity. This strength will help to improve wear resistance and extrusions resistance in higher pressure / temperature applications.

Modified PTFE, Carbon & Carbon Fiber Filled – This is a favorite at Eclipse. Blended to drastically improve wear resistance and extrusion resistance in dynamic sealing applications, we have great success putting this into long running applications when typical PTFE would have been long worn away.

Modified PTFE, 25% Glass – Higher glass fiber content for applications requiring even more strength than EZ031.

Modified PTFE, PTFE & Polyimide Blend – Specialty blended material for added wear resistance.

Notice:

Technical Information, test data and advice provided by Eclipse Engineering are based on information and tests we believe to be reliable and are intended for persons with knowledge and technical skill sufficient to analyze test types and apply adequate safety factors for the given application. Because actual application conditions vary widely, these values are intended for comparitive purposes only and the suitability of this material is ultimately left to the end user.

EZ030

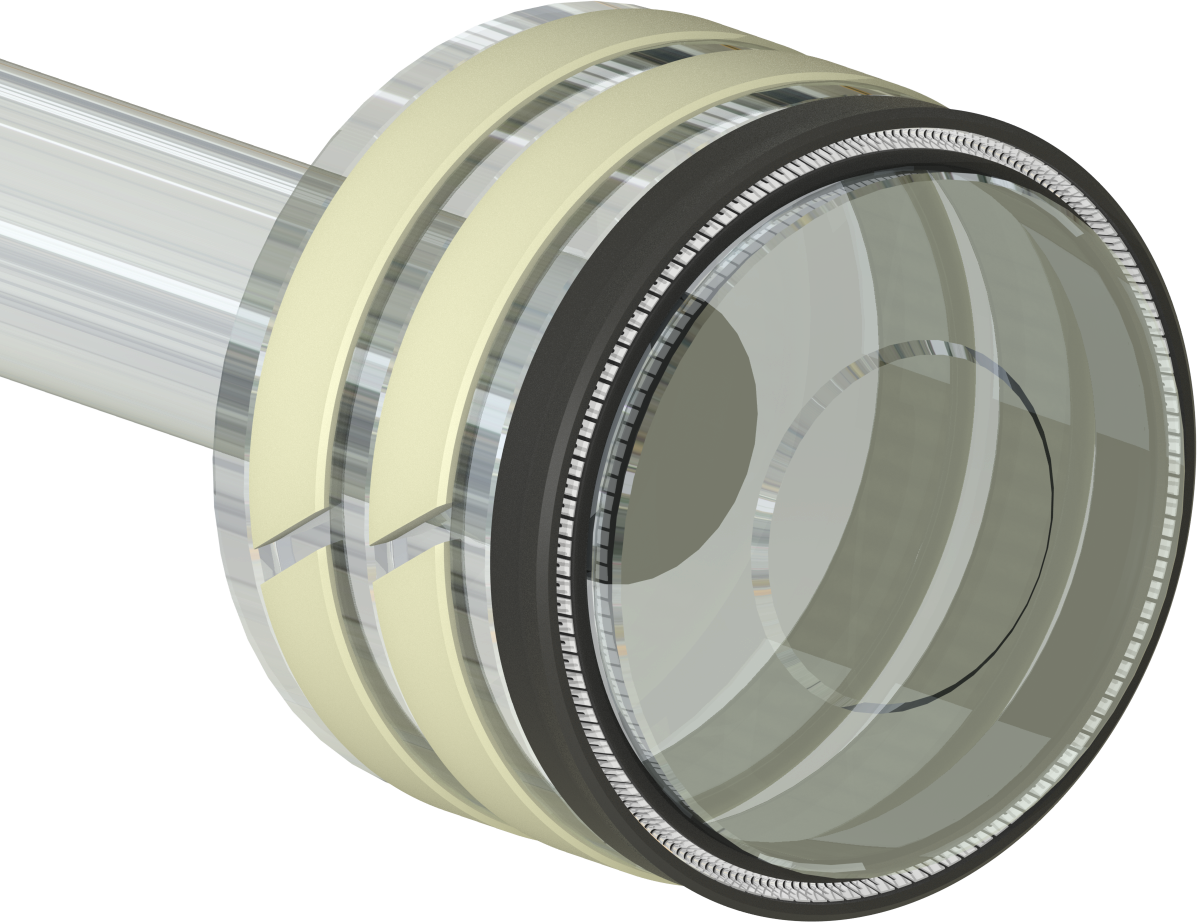

Eclipse EZ030 is the unfilled grade of our modified PTFE. It maintains all the benefits of standard PTFE in terms of chemical compatibility, friction characteristics, and temperature range. Its advantage over standard PTFE lies in the fact that the modified version allows better material adhesion during processing, resulting in a denser finished structure. The denser structure allows EZ030 better machined finishes on seals as well as greater permeation resistance. This results in a seal that is unmatched for service in gaseous media such as oxygen, hydrogen, nitrogen and natural gas. Common applications for EZ030 are couplers, ball valves and seats.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4894 | 2.16 | (-) |

| Tensile Strength at Break | ASTM D4894 | 4600 | psi |

| Elongation at Break | ASTM D4894 | 450 | % |

| Tensile Modulus | ASTM D638 | 94,250 | psi |

EZ031

This blend is a glass filled version of EZ030, which allows application in high pressure service. The addition of a moderate amount of glass greatly increases the sheer and compressive strength of the material as well as adding wear resistance. This extends the specification of EZ materials from seal elements into other mechanical parts such as back-up rings, wear rings and high temperature seats.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.22 | (-) |

| Tensile Strength at Break | ASTM D4745 | 2500 | psi |

| Elongation at Break | ASTM D4745 | 300 | % |

| Tensile Modulus | ASTM D4745 | 500/700 | g/l |

EZ032

This blend is a highly filled version of EZ030 for the most demanding applications. Proprietary blending technology is used to evenly disperse carbon and fiber fillers throughout the base resin imparting wear resistance and high temperature capabilities. As an example, EZ032 is being used as wear rings at 575°F (302°C) continuous operating temperature. What makes EZ032 a unique material is how the resin blending allows for a high level of fillers to be added without degrading the properties of the base resin. Typically, higher filled resins do not lend themselves to being used in seals. In the case of EZ032, the desired properties of pliability and resiliency still remain; making this material useful in critical sealing applications where high pressure-velocities are present. EZ032 is a common upgrade for rotary applications where filled PTFE materials (glass, carbon, PPS) are often specified for wear life. In those applications, EZ032 offers additional seal life with equivalent or better sealing efficiency. Running on hardened surfaces, EZ032 makes an excellent choice for gear pump seals, mechanical face seal elements and downhole seals.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.05 | - |

| Tensile Strength at Break | ASTM D4745 | 2000 | psi |

| Elongation at Break | ASTM D4745 | 25 | % |

| Hardness | ASTM D2240 | 58 | Shore D |

| Bulk Density | ASTM D4745 | 500 | g/l |

| Deformation Under Load | Based on ASTM D621 | 2.0 Initial 1.0 Permanent | % (Test Conditions 2000 psi, 70°F) |

| Deformation Under Load | Based on ASTM D621 | 0.8 Initial 0.9 Permanent | % (Test Conditions 600 psi, 500°F) |

EZ034

| Typical Properties | Test | Value | Units | |

|---|---|---|---|---|

| Specific Gravity | ASTM D4745 | 2.25 | - | |

| Tensile Strength at Break | ASTM D4745 | 2280 | psi | |

| Elongation at Break | ASTM D4745 | 300 | % | |

| Tensile Modulus | ASTM D4745 | 504 | g/l | g/l |

EZ036

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D4745 | 1.95 | 1.95 |

| Tensile Strength at Break | ASTM D4745 | 2750 | psi |

| Elongation at Break | ASTM D4745 | 275 | % |

| Hardness | ASTM D2240 | 60 | Shore D |

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!