Why Eclipse Engineering Exceeds as Your Seal Distributor

At Eclipse, reliability is not an accident. Our customers’ expectation is that each seal we design and manufacture is to print, and meets the quality requirements that are specified.

Quality and reliability are part of who we are. Our culture at Eclipse Engineering is to place our customers at the center of our purpose. If we succeed in satisfying our customer, we will succeed in our goals.

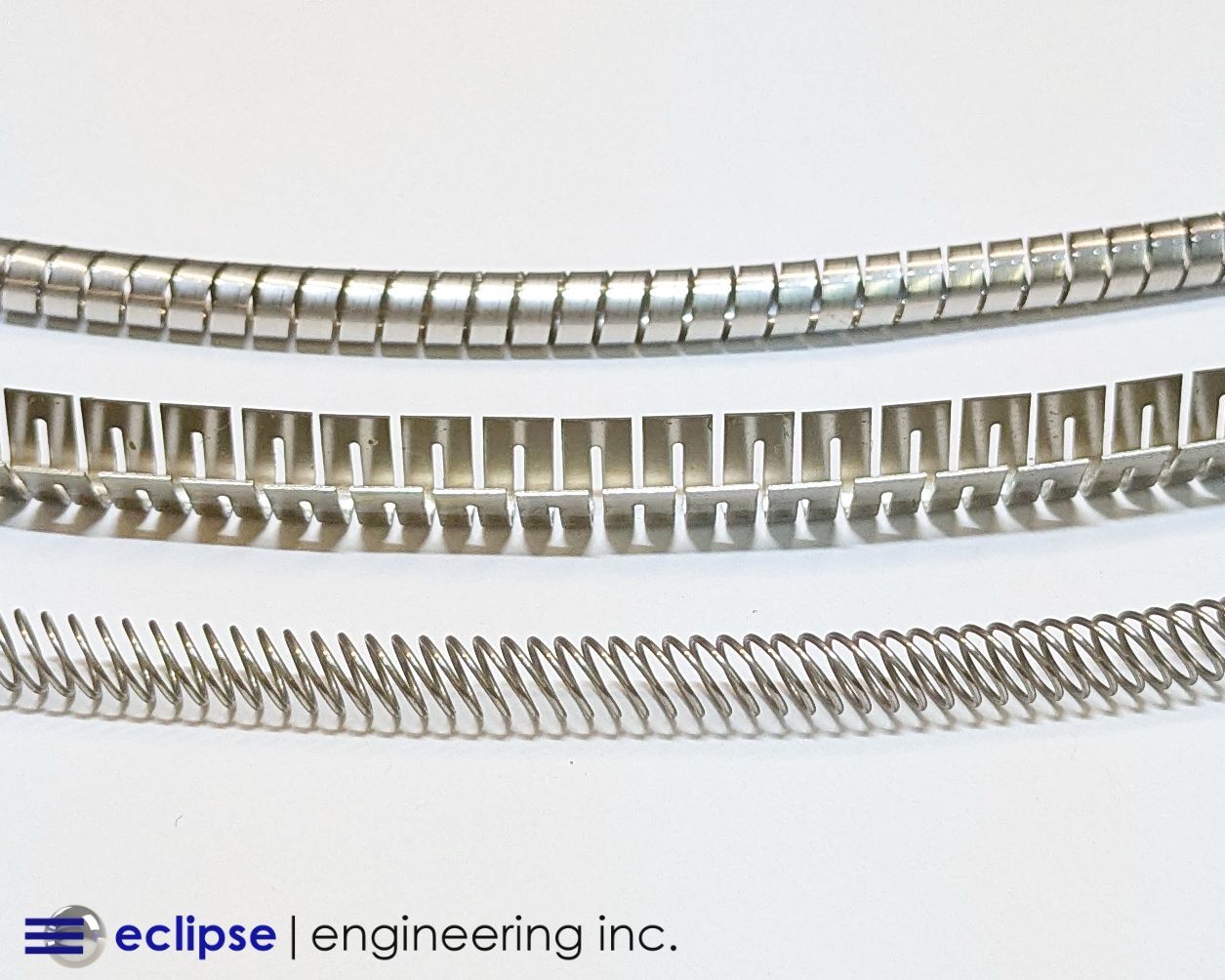

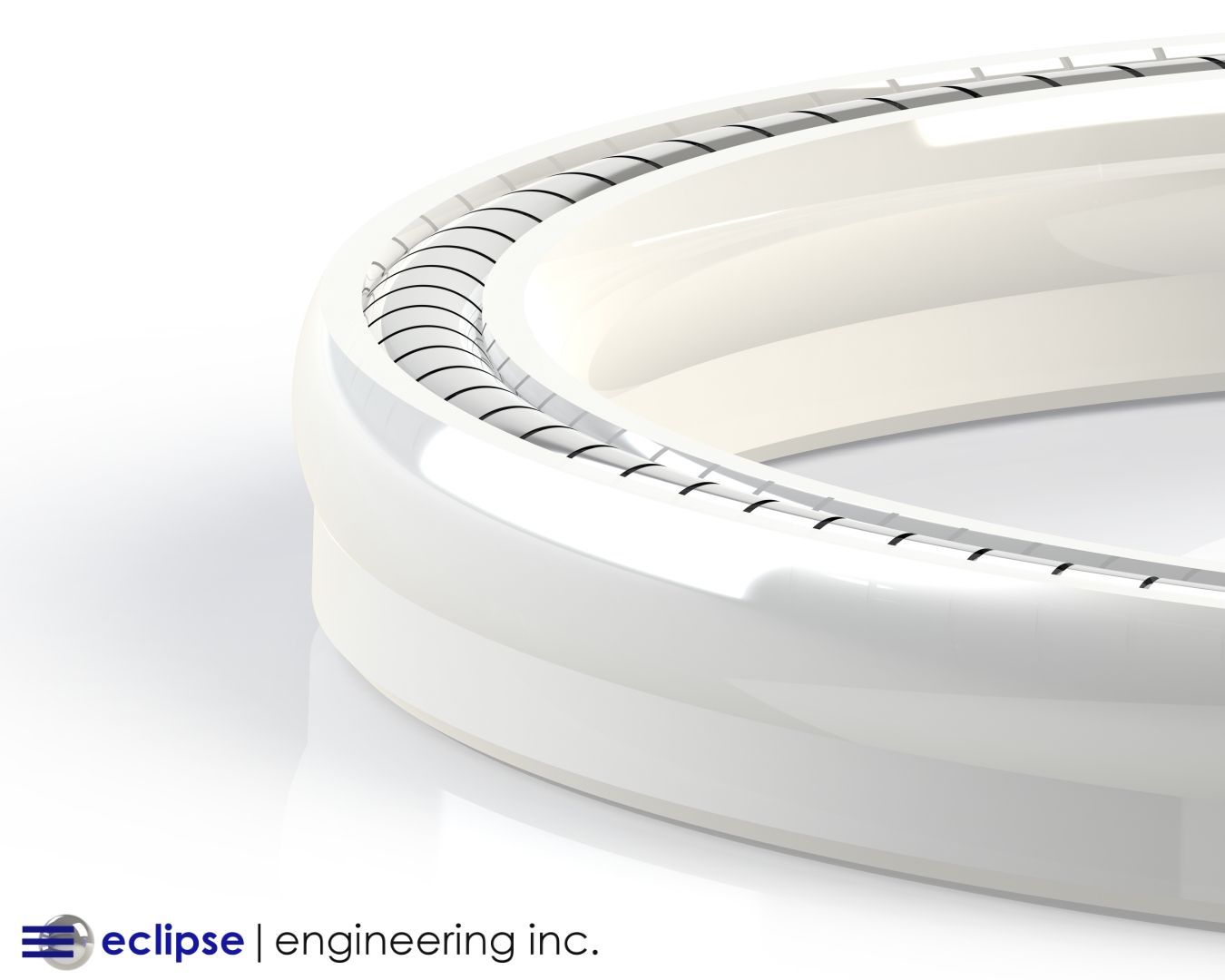

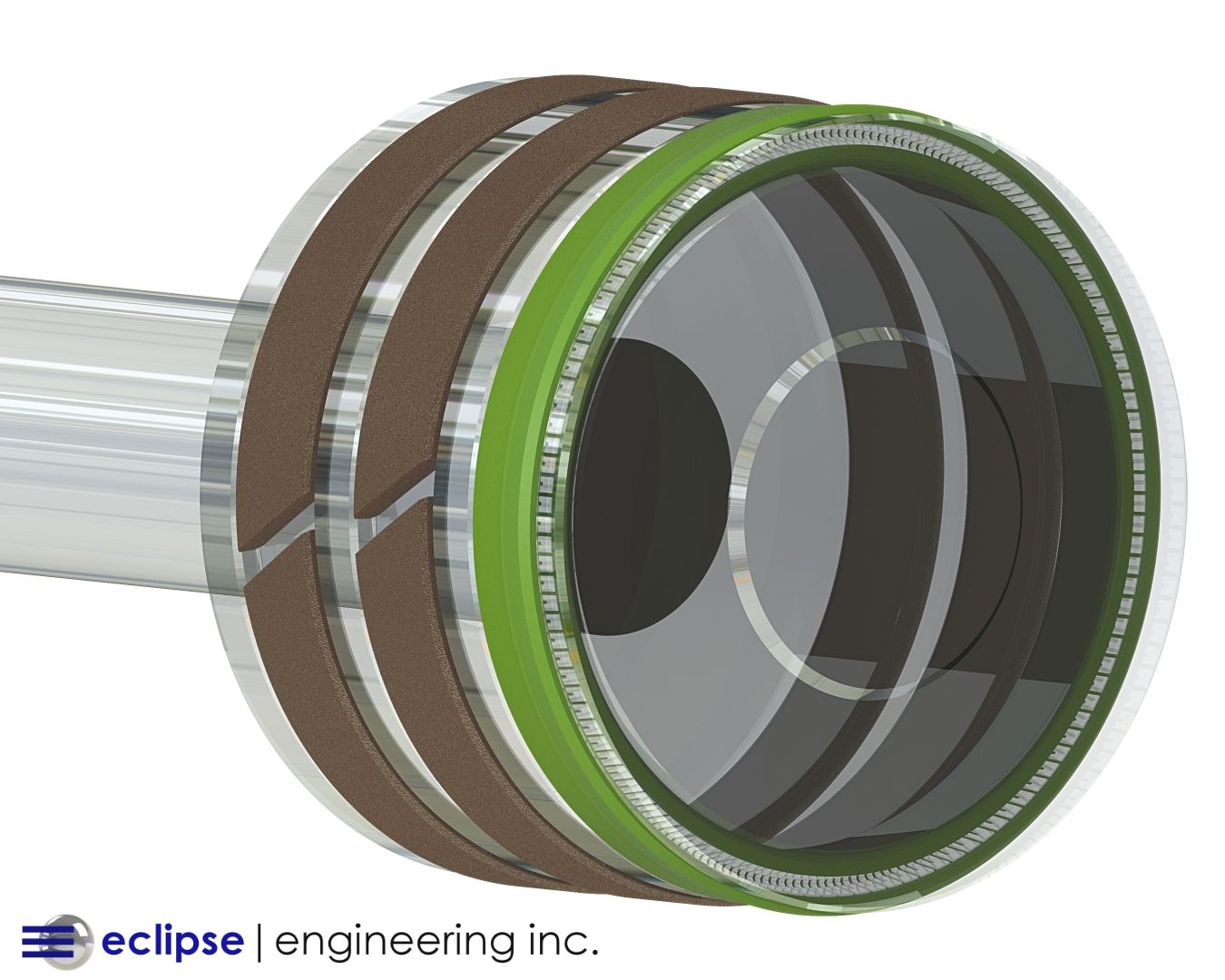

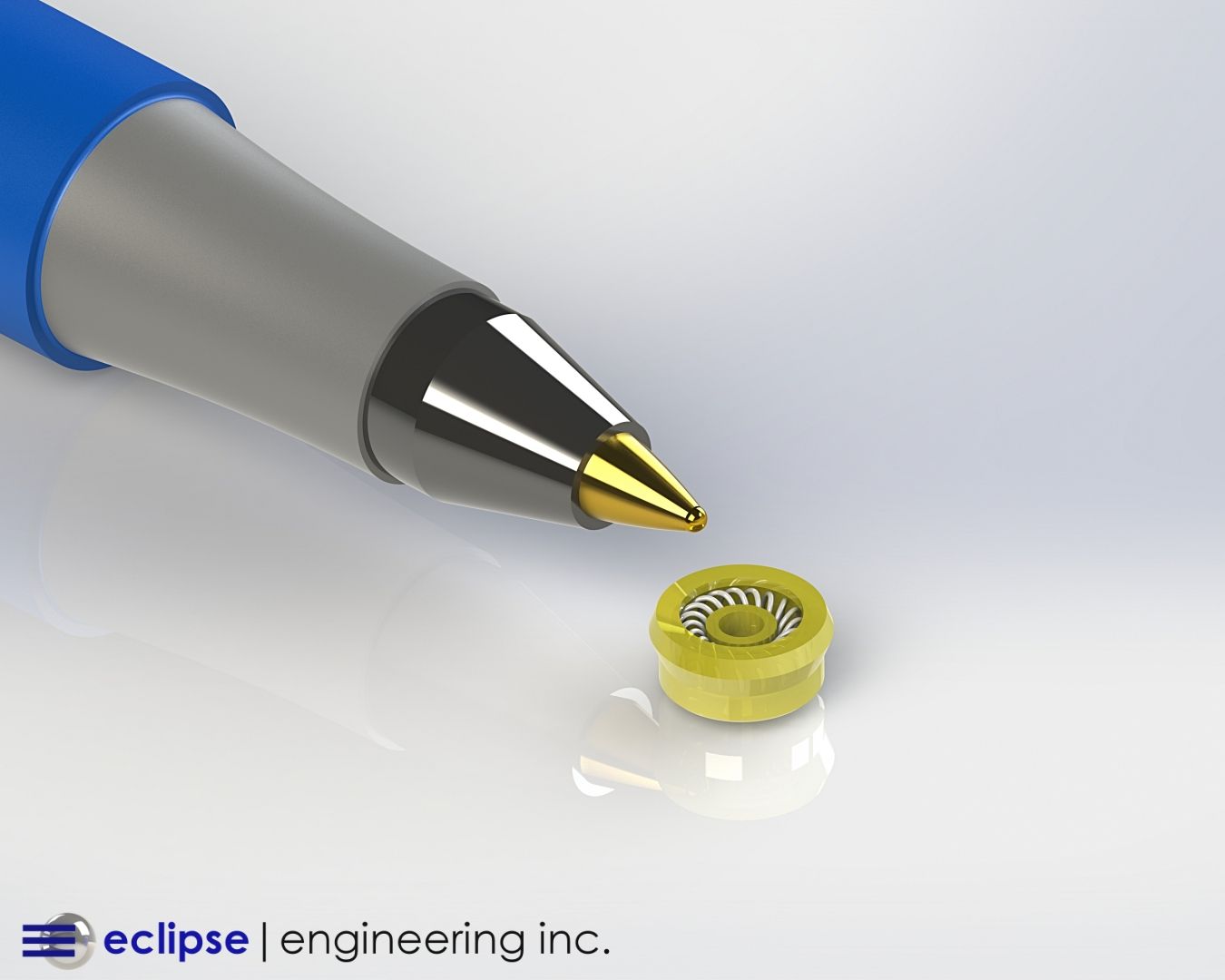

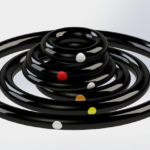

Seals are always a part of a system to retain or exclude a fluid. A method for improving reliability is creating sub-assemblies, or cartridges, which retain the seal with other components.

Installation is improved because there’s little or no chance of seal damage. And field replacement can be accomplished by cartridge replacement again, allowing for improvement of repaired units without risk of seal damage.

Single Source for All Components

At Eclipse, we often source all the components, build the seals and build up the sub assembly. This reduces part count for the OEM, reducing the overall cost of the end product due to sub assembly build up and installation.

We Handle Repackaging and Reselling

We can also package for resale of our OEM’s, preparing the product to move from the shelf into the rebuilder’s hands, with a high probability that the rebuild will be successful.

Eclipse prepares kits for OEM resale into the rebuild market, saving time and resources by pulling all the soft replaceable components for seal rebuild. We can manage the purchasing of all the components and brand package for resale.

O-Rings can be dotted or individually packaged, or tagged for easy identification for the end customer during their build cycle.

As an authorized DuPont Kalrez distributor, we can supply genuine Kalrez products in their original packaging. They can be supplied individually or packaged in kits for resale.

Certification, Delivery and Inventory Maintenance

Certification of products is available depending what the requirements are.

Products can be dropped shipped anywhere in the world.

We also can plan delivery and maintain inventory to smooth out manufacturing insuring products will always be available regardless of the production schedules.

Reliability, delivery, quality, and price will continue to be our customers focal point. Contact us today with any customer service question or need »