The Advantages of Crimped Can Seals

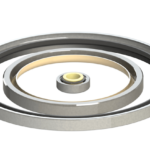

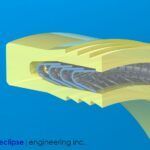

Rotary seals are often secured in sealing hardware by crimping the sealing element in a metal can. One of the most common rotary seals is a molded rubber lip seal in a can.

While not crimped, the can retains the sealing element, and stops the seal from rotating in the gland. Rotary sealing elements for low pressure (under 15 psi), are often nitrile or Viton rubber sealing elements.

This style of seal comes in many cross sections, and may include garter springs to help the seal stay engaged with the shaft. These seals are typically low in cost, and produced in high volume.

These seals are found in many low-pressure applications. However, as the pressures begin to climb over 10 psi and speeds run over 500 ft/min, friction generates heat, which accelerates wear on the rubber element and in turn begins to wear the mating shaft material.

Overcoming Friction

Friction or the resultant heat is the largest concern in rotary service.

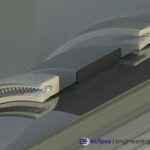

The crimped can seal with PTFE (Teflon) elements can run with pressures in excess of 500 Psi and PV (pressure- velocity) reaching over 350,000psi-ft/ min. The crimped can allows these elements to remain secure.

The crimped case seal causes all the relative motion to remain at the sealing lip interface. With the crimped can, we have the opportunity to install multiple lips or seal cross sections to handle a variety of loads. This allows us to control leakage, and keep friction to a minimum.

We can seal most any fluid or run dry sealing gases with little or no lubrication. With widely varying temperatures, we can include springs to maintain seal contact, offset some eccentricity of shafts, keep dirt out or keep very light loads.

Adding a Spring to Crimped Case Seals

With the help of a spring, the crimped case seal may seal pressures and vacuum in the same cavity. We can even seal low-pressure with the lips facing backward, while excluding other fluids into the system.

The beauty of the crimped case seal is that it can be manufactured to meet your requirements, when your needs exceed the very common rubber lip seal.

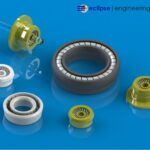

Eclipse Engineering manufactures crimped rotary lip seals with inside diameters from under .060 to over 25 inches in diameter.

The MicroLip Seal

Our latest product, the MicroLip , allows for extremely small cross sections. This product also offers a new variety of spring combinations and retention methods that haven’t been seen in the sealing industry before.

MicroLips are produced with a variety of materials to accommodate shafts with hardness in the “B” scale. We’ve even developed a MicroLip that seals on the OD surface, instead of just the ID.

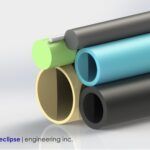

Different Materials of Crimped Can Seals

We can manufacture seals in most metals. As an OEM, we can manufacture small volume quantities or amounts into the thousands.

This style of seal allows cost savings in remote hydraulic motors, allowing the removal of the case drain hose. It can also be installed using an O-Ring in the hardware to improve removal and installation of the seal.

It can be supplied in an external cartridge for ease in field replacement — although this seal with the correct design is fairly easy to remove and replace in standard rubber lip seal hardware. It can be supplied with exterior coatings to help improve seal-ability on the static side for compromised hardware.

Rotary lip seals using Teflon elements offer the user many options in sealing. The MicroLip allows for low profile seal ability.

A variety of fluids and temperatures affords the user a broad operating envelope in one package, handling pressures from vacuum to 500 PSI. This combination of crimped can seals will handle a variety of applications when a rubber lip seal is not your solution.

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!