UHMWPE | EU

Eclipse EU materials are compounds based on ultra-high molecular weight polyethylene (UHMWPE). Although it has a limited upper used temperature of 180°F (82°C), UHMW is nearly unsurpassed in its ability to resist abrasion. Eclipse pushes the limits of this material with particle filled EU compounds that further the abrasion and temperature use limits. This resistance to wear combined with low friction and very low water absorption characteristics allow EU materials to be utilized in a broad range of applications.

Many industries rely on water based fluids in process. This poses an issue, due to the fact that water offers little or no lubricating benefit to seals. In these cases, EU materials are an excellent choice. Eclipse EU material properties are not affected by water, making this material prevalent in food processing machinery, paint and pigment equipment, pulp and paper processing, as well as environmental barrier components where exclusion of debris is desired.

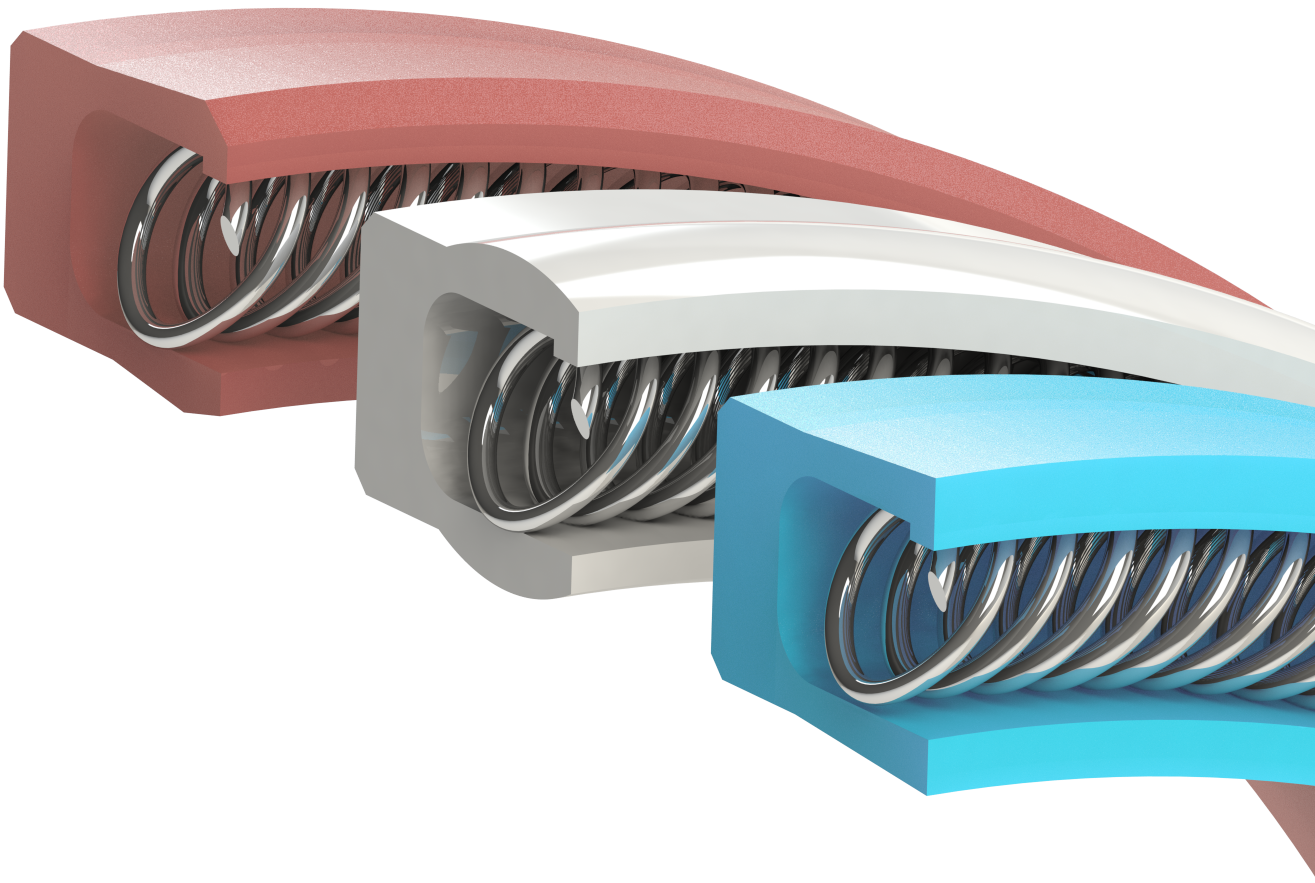

Eclipse makes use of UHMW’s superior abrasion resistance in spring energized seal designs that effectively seal and scrape abrasive and viscous media. Adhesive systems with epoxy or urethane formulations are common uses for Eclipse EU materials. Paint and slurry systems are especially troublesome for most polymers, but proper design and use of Eclipse EU materials allows the specification of long wearing seal elements. Facilities that require years of use before rebuild, such as water treatment plants, dam gates and wind turbines are common consumers of this material.

Available Materials

Ultra High Molecular Weight Polyethylene, 100% Virgin – Meets FDA requirements for food processing and handling. It is best suited for Medium mechanical duties in water, Oil Hydraulics, pneumatic, and unlubricated applications

Ultra High Molecular Weight Polyethylene with microsphere additive, Ceramic Filled – Improved tensile strength and wear resistance will increase part life in severe linear abrasive applications.

Notice:

Technical Information, test data and advice provided by Eclipse Engineering are based on information and tests we believe to be reliable and are intended for persons with knowledge and technical skill sufficient to analyze test types and apply adequate safety factors for the given application. Because actual application conditions vary widely, these values are intended for comparitive purposes only and the suitability of this material is ultimately left to the end user.

EU000

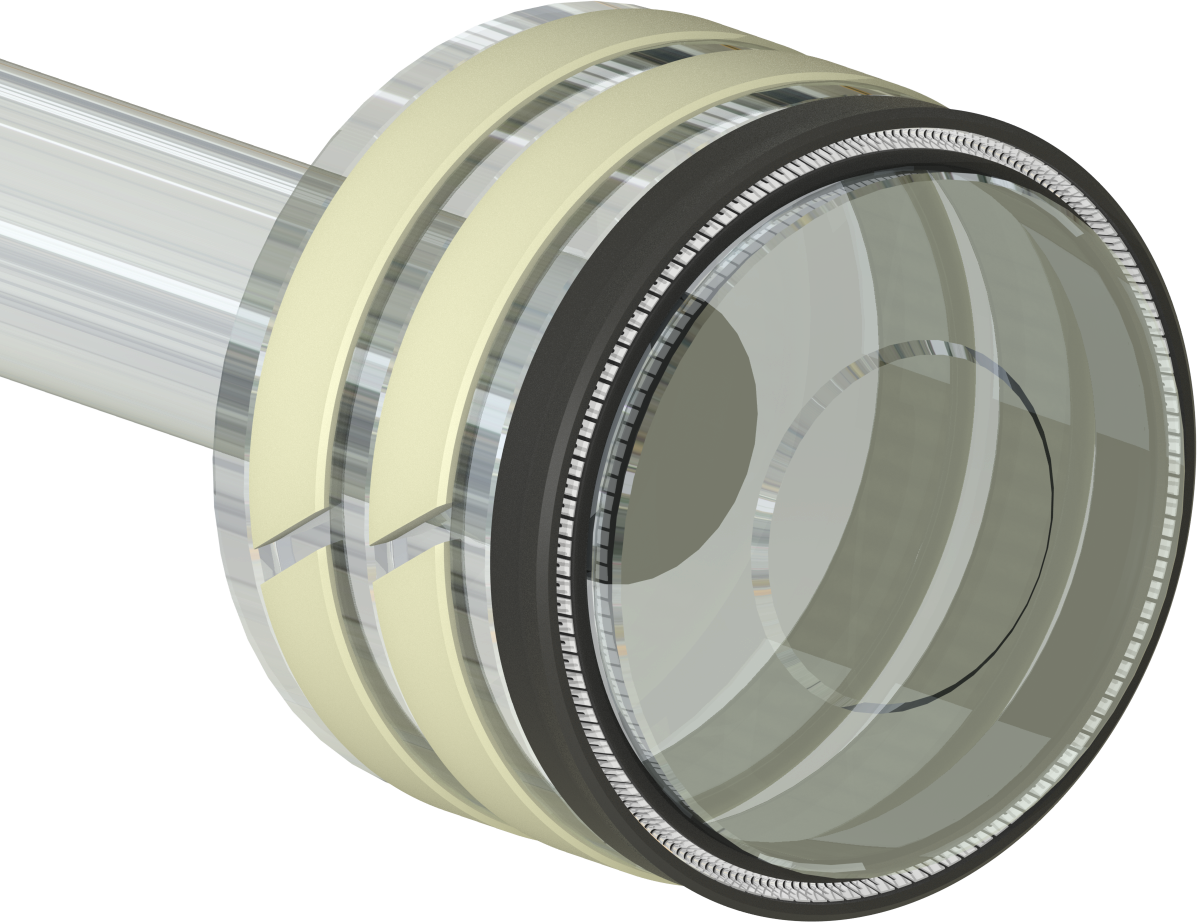

EU000 is the Eclipse unfilled grade of premium UHMW. Chemically, it has a very simple structure comprised of long chain carbon-hydrogen bonds. The simplicity of the formulation, along with the strength of the carbon-hydrogen bonds, imparts a set of unique and useful properties. The most renowned of these properties is resistance toabrasion. At temperatures below 150°F (66°C), Eclipse EU compounds are unparalleled in their resistance to abrasion. This abrasion resistance is put to use in industries that deal with paint, pigment and epoxy based media. When designed and loaded properly, seals manufactured from EU000 are capable of operating for millions of cycles with minimal wear.

Many polymers consist of polar (charged) molecules. Since water is a polar molecule, it will be attracted to, and absorbed into many polymers. EU000 chemistry consists of a non-polar molecular chain that eliminates any reaction or absorption of water. This feature makes EU000 a top choice for any application that involves water based media. This is useful in seals that are exposed to coolant or slurries and can be designed into very effective excluders to scrape mud out of a sealed cavity.

EU000 is FDA compliant per 21 C.F.R 177.1550. When used under these guidelines, EU000 is an excellent choice for piston seals in food filling devices and for seals used in analytical, pharmaceutical and medical equipment.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 0.93 | g/cc |

| Tensile Strength at Break | ASTM D638 | 5800 | psi |

| Elongation at Break | ASTM D638 | 300 | % |

| Tensile Modulus | ASTM D2240 | 66 | Shore D |

EU038

Eclipse pushes the limits of UHMW by offering filled grades such as EU038. The addition of finely dispersed hardened particles imparts extra abrasion resistance to the base polymer. Eclipse has developed special processes for manufacturing seal shapes from this material, allowing improved performance over EU000 where hardened dynamic surfaces are available. EU038 should be considered in applications that are at moderate temperatures, but exposed to high pressure and aggressive media. High Pressure Liquid Chromatography (HPLC) equipment can benefit greatly by utilizing this material.

| Typical Properties | Test | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D792 | 0.96 | g/cc |

| Tensile Strength at Break | ASTM D638 | 5500 | psi |

| Elongation at Break | ASTM D638 | 300 | % |

| Tensile Modulus | ASTM D2240 | 68 | Shore D |

"We started Eclipse with the premise that if we could solve enough of our customers problems they would continue to come back to us for solutions regardless of the type of products we offered."

What Can We Help You With?

Start a project request form and give us the specifics of your project. Our team will review and be in touch with you shortly!

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!