The Right Fillers for Optimum PTFE Performance

Polytetrafluoroethylene (PTFE) resin is a highly effective material for seal consumers due to its extremely low friction, high heat tolerance and chemical inertness.

With the right additives, PTFE resin can perform even better in terms of strength, thermal performance, chemical resistance and abrasion.

However, there are a few design considerations when using PTFE resin, particularly when combined with glass fiber and bronze.

A Quick Intro to PTFE: A Breakthrough Material

A common household form of PTFE is Teflon, which you’ll recognize as the slippery plastic used in non-stick frypans.

PTFE was discovered in the 1930s as an accidental byproduct in chlorofluorocarbon refrigerant production. It’s a synthetic compound consisting wholly of carbon and fluorine — a fluorocarbon.

PTFE is hydrophobic, so doesn’t get wet due to the high electronegativity of fluorine. It’s also chemically non-reactive, mainly because of the ‘independent’ strength of the carbon–fluorine bonds. This suits the resin well for reactive and corrosive chemical environments.

Where it is used as a lubricant or seal, PTFE has the huge benefits of reducing friction, wear and energy consumption of machinery.

Making a Great Material Even Better

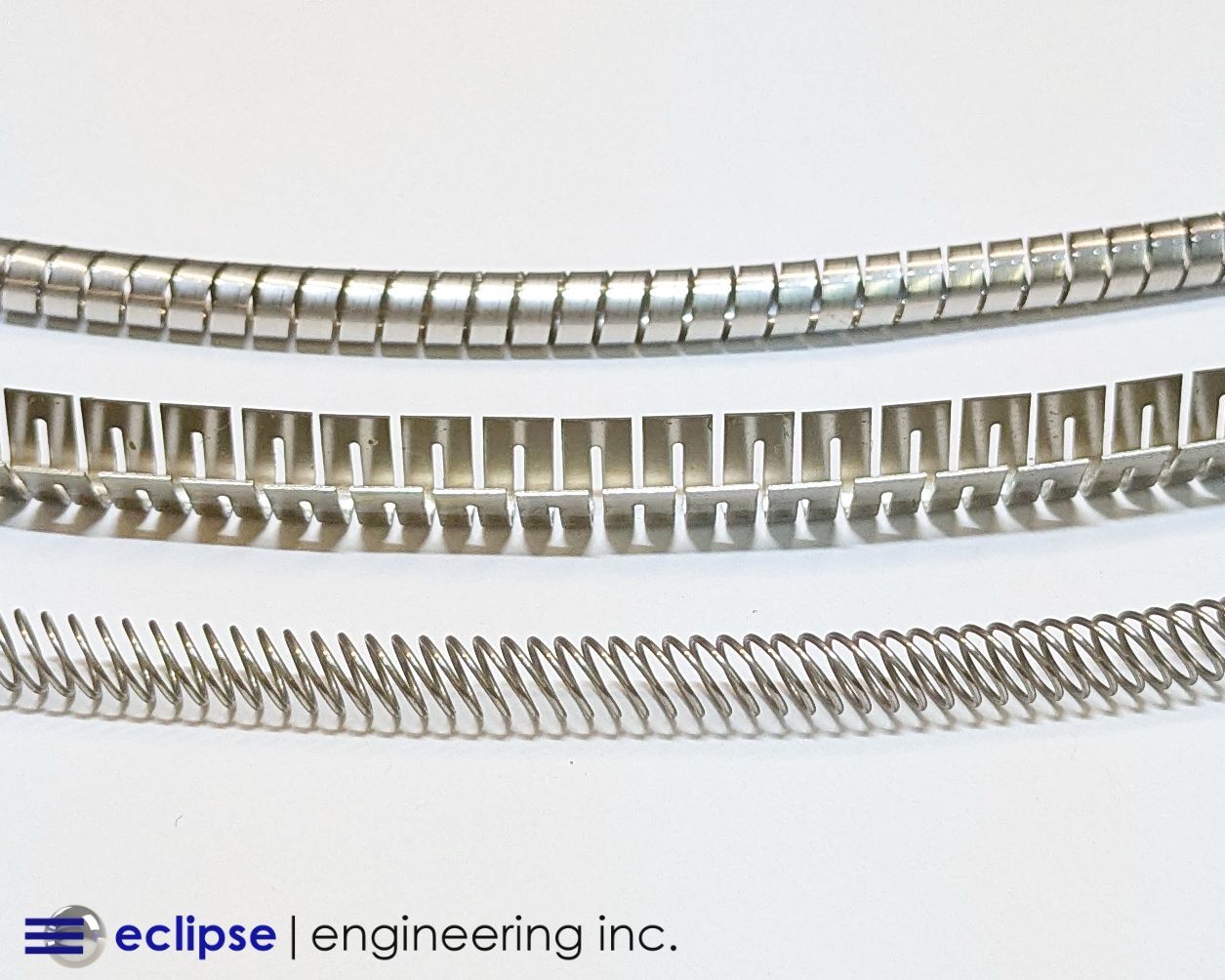

After extensive experimentation and time-tested performance, the following additives/fillers have come to be strategically used to enhance PTFE performance:

Glass Fiber (typically 5–40%)

Improvements:

- Creep resistance

- Compressive strength

- Pressure tolerance

- Chemical compatibility/inertness (except for strong alkalis and hydrofluoric acid)

- Wear resistance and durability

- Similar friction to virgin PTFE

There are a couple of cons to glass fiber, including abrasion on mating parts and discoloration of finished parts.

Ideal for:

- Piston rings

- Backup rings

Molybdenum Disulfide (MoS2) (typically low %)

Improvements:

- Hardness and stiffness

- Friction

- Lubrication

- Wear resistance

- Chemically unreactive (except with oxidizing acids)

- Best when combined with glass and bronze

Ideal for:

- Dynamic seals

Carbon powder (typically 5–15%)

Improvements:

- Hardness

- Compressive strength

- Deformation resistance

- Thermal conductivity

- Permeability

- Abrasion reduction

- Wear resistance and reduced friction when combined with graphite

- Antistatic (electrically conductive)

Ideal for:

- Rotary seals

- Sliding applications

- Piston rings (with graphite)

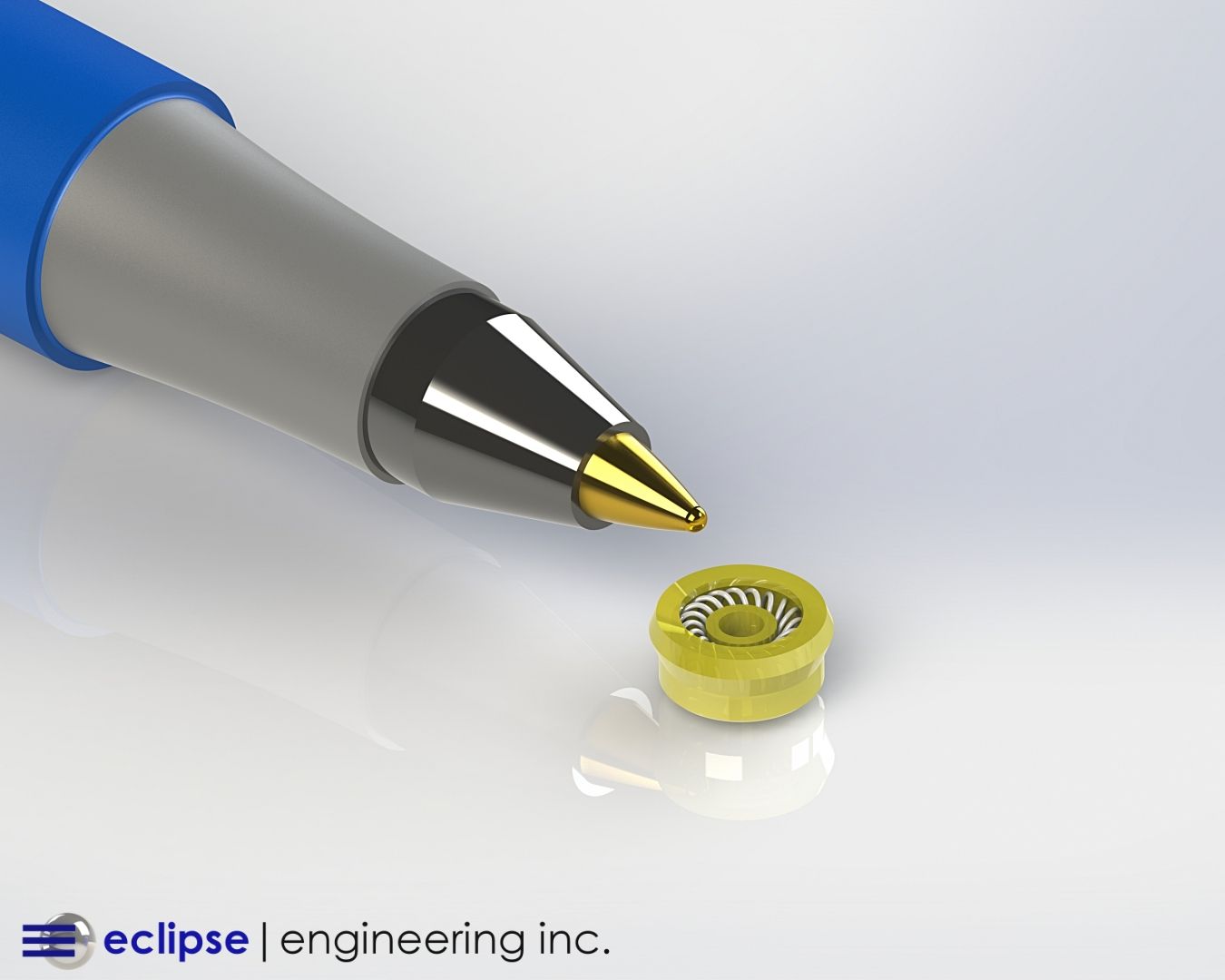

Carbon Fiber

Improvements:

- Creep resistance

- Chemical inertness

- Lightness

- Wear resistance

- Abrasion reduction

Ideal for:

- Bearings

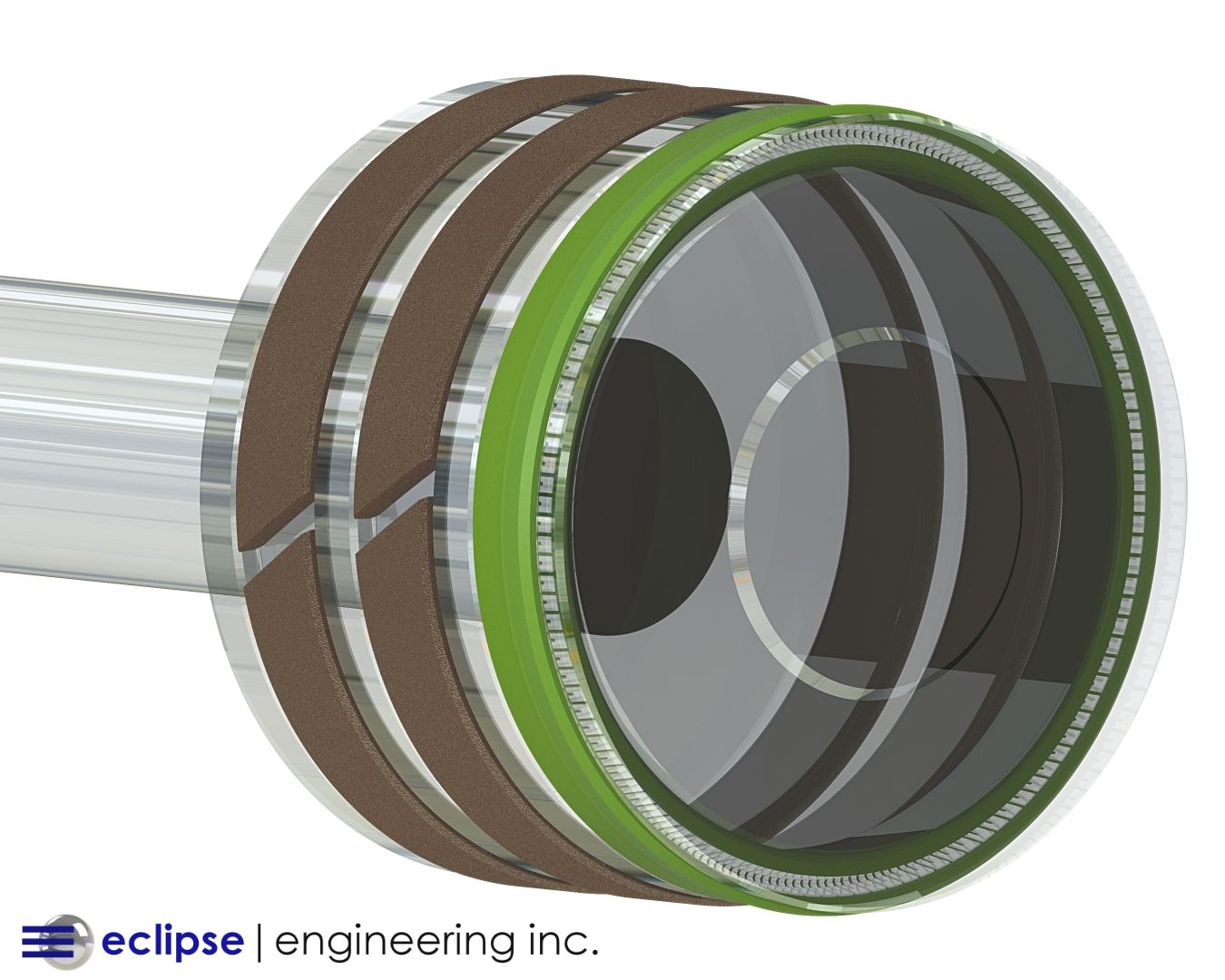

- Seal rings e.g. water pumps and shock absorbers

Graphite (typically 5–15%)

Improvements:

- Friction

- Lubricity

- Wear resistance

- Reduced wear against soft metals

- High load-carrying capability in high-speed contact applications

- Chemically inert

- Great combined with glass and carbon

Ideal for:

- Pumps

Bronze (typically 40–60%)

Improvements:

- Wear resistance

- Thermal conductivity

- Creep resistance

- Pressure tolerance

Disadvantages:

- Chemical reaction

- Oxidizes

Ideal for:

- Hydraulic systems

- Master cylinders

- Drug manufacture seals

- Not for electrical or corrosive applications

Pigments

Improvements:

- Color coding of seals

- No performance change to pure PTFE

Put to Profitable Use

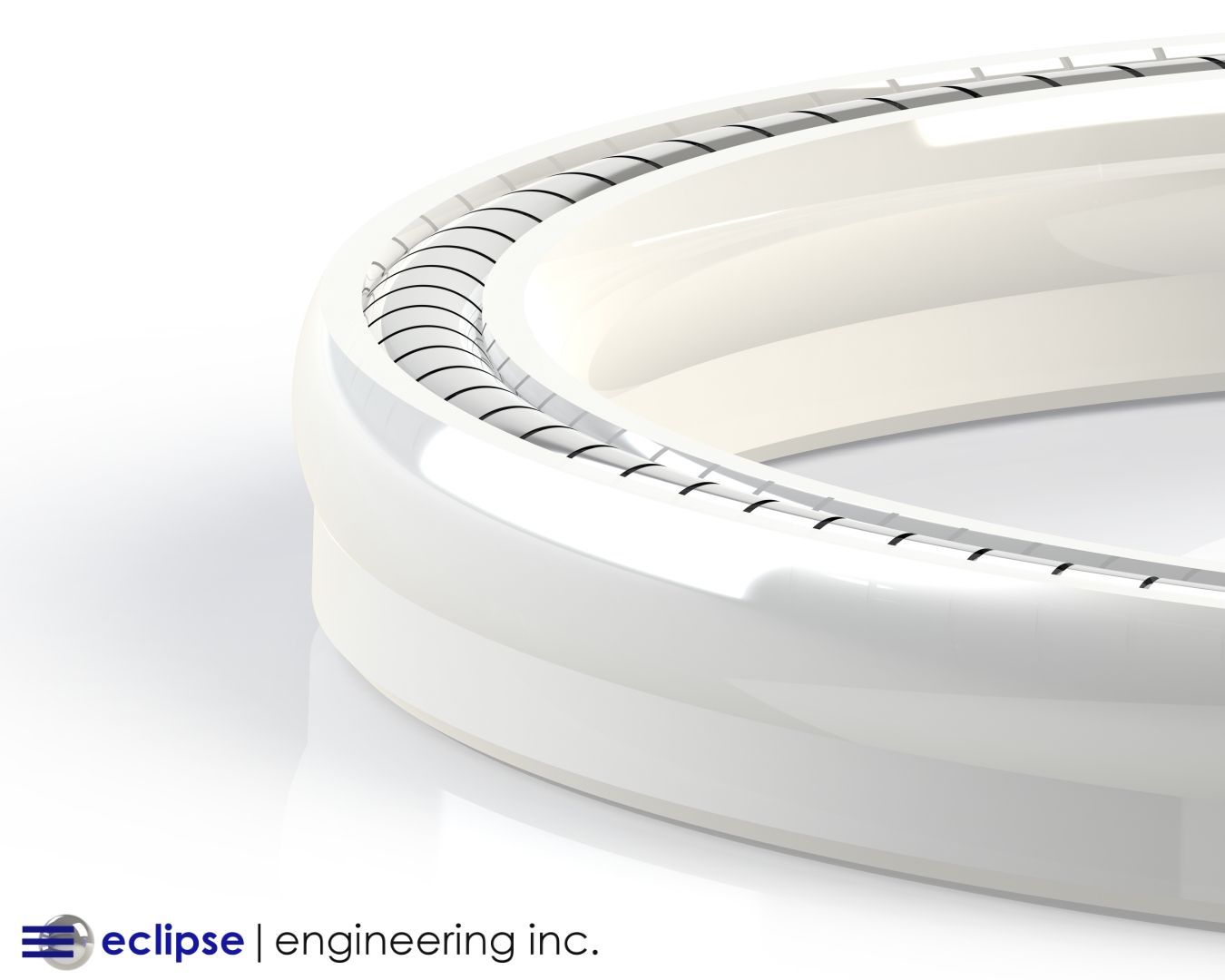

PTFE seals , with their exceptional performance, are used for a myriad of applications, including:

- Motors

- Gearboxes

- Pumps

- Bearings

- Compressors

- Extruders

- Valves

- Blowers

- Spindles

- Mixers