How HEPA Filters and Boundary Seals Help Protect Us During Pandemics

Boundary seals that help keep a certain environment sealed in while keeping the world out are everywhere.

If you look around your home, you may be surprised to see there are seals surrounding every door — and not just at the bottom. Your oven, microwave, and of course refrigerator door all have seals around them.

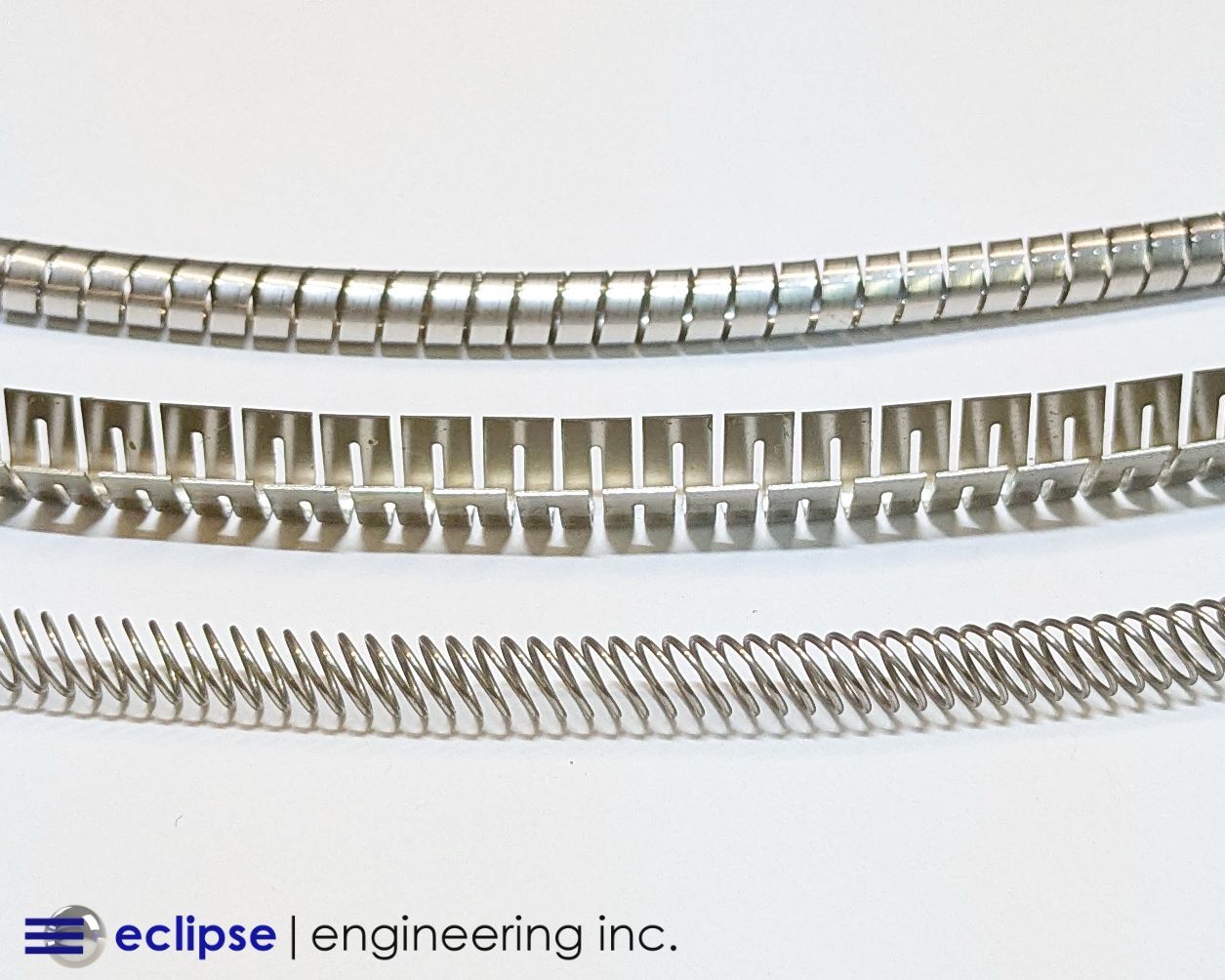

All these seals are different, yet they perform the same function. Your microwave is especially interesting, as its primary purpose is to keep microwaves from escaping the chamber that’s cooking your food. Your refrigerator seal has a magnet built into it, which keeps the door sealed shut.

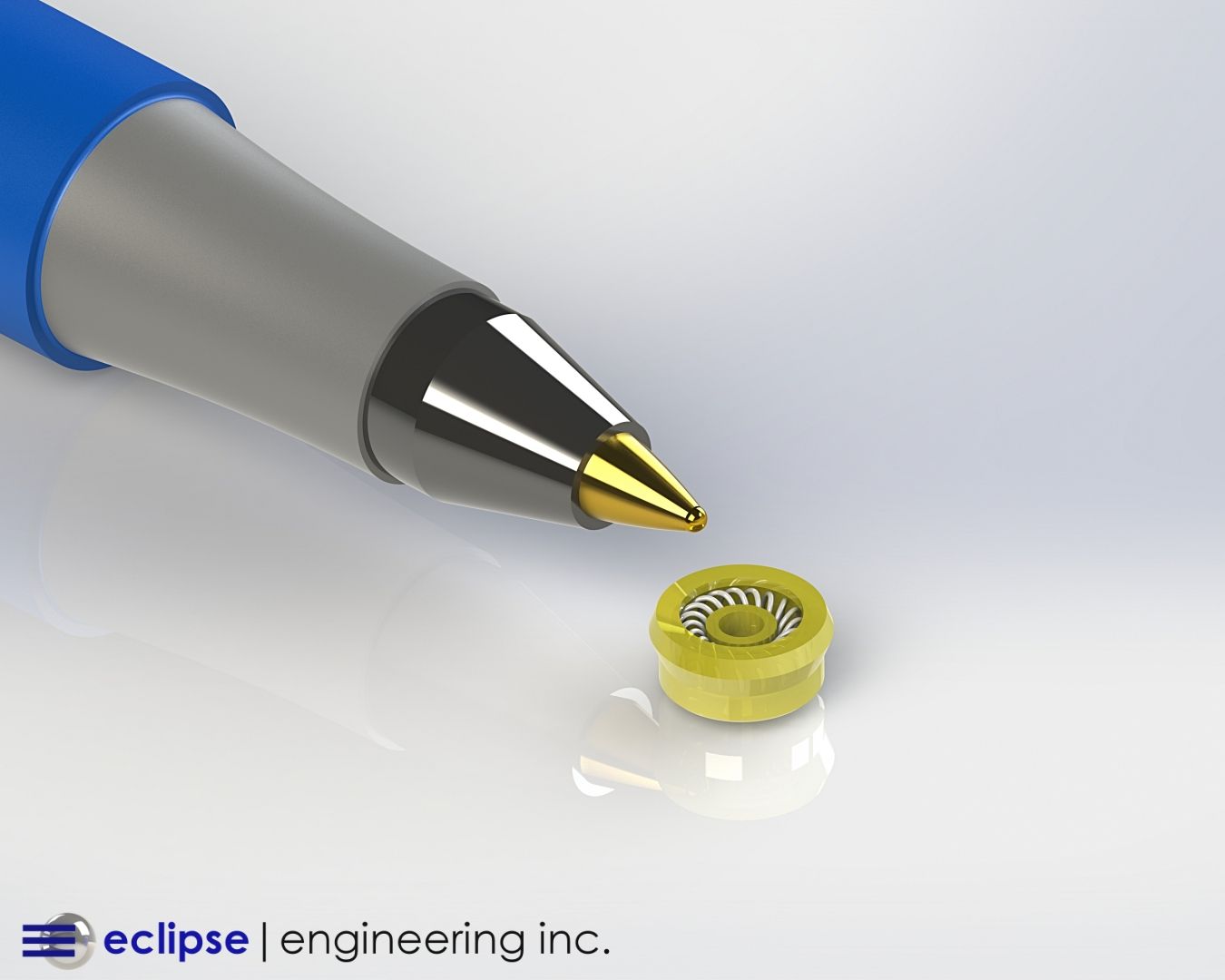

Boundary seals are also found in many cell phones and electronic devices, keeping them water-resistant or water-proof (depending on the manufacturer). And in the industrial world , we have seals to create explosion-proof boxes in hazardous environments. The simple O-ring is found at the end of every cylinder cap to keep fluids in and the environment out.

We all go through great expenses to seal our houses from the outside with sturdy doors, only to find that we need fresh air here and there. Our windows have a series of seals around them keep the heat or the cold outside, but can be opened to allow fresh air when we want it.

In the same way that boundary seals work, the pandemic has many of us thinking about how to keep hazardous germs from entering into our homes. And if we have to fly, we may wonder how fresh the air is in the cabin, and if viruses have an easier time spreading inside of an airplane.

Boundary Seals in Aviation

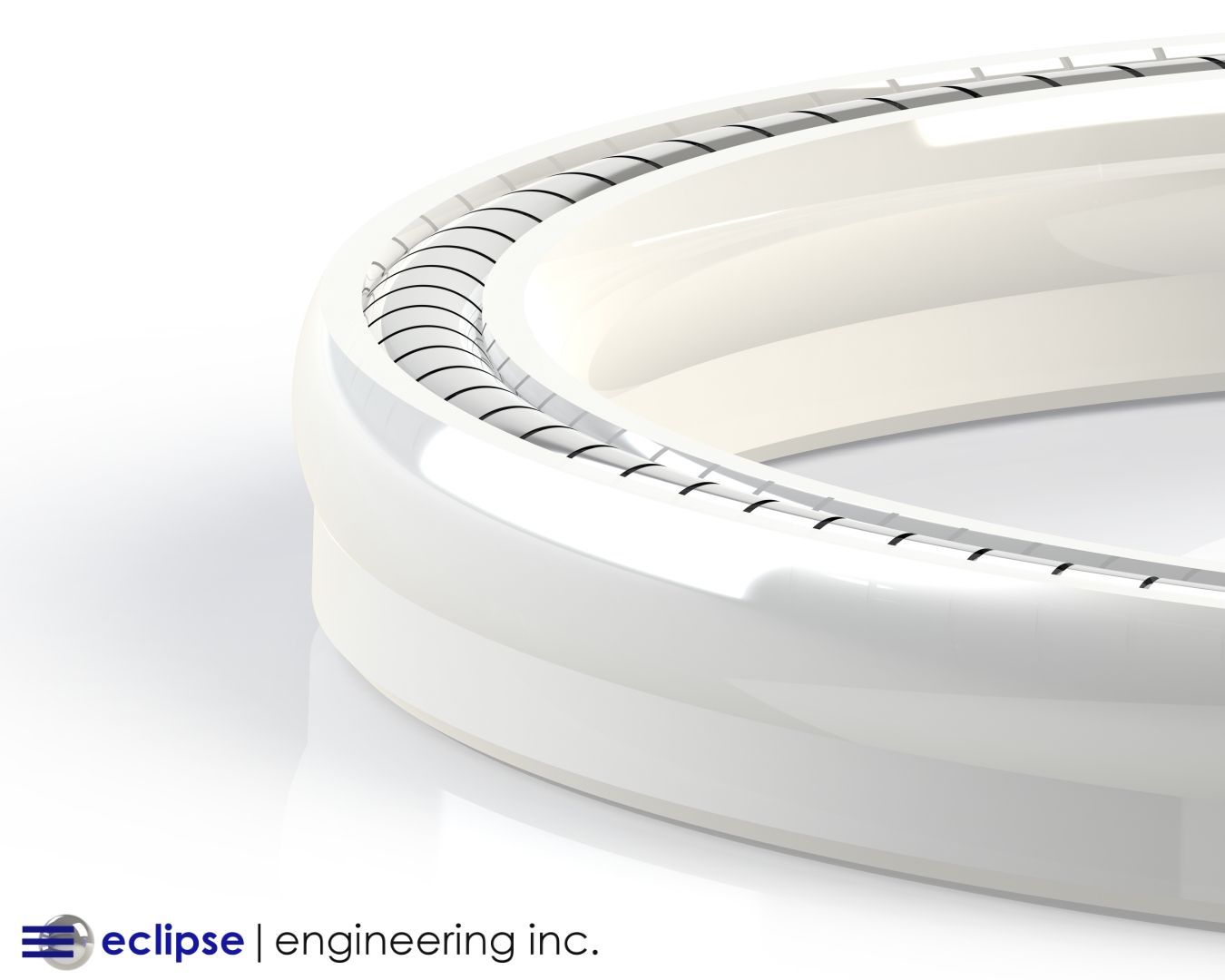

Let’s begin with general aviation aircraft with pressurized cabins. The door’s seal is in the form of a bladder, which you pump up with the same type of bulb often found on a blood pressure cup.

Doors are especially difficult to seal, as they’re required to open and close. A rubber seal that would compress and seal the door completely would make the door too difficult to open and close.

After the door is closed, the pilot pumps up the bladder to seal the door. As the engines are wound up, the flight deck begins the process of pressurizing the aircraft. A pressure system from the engine maintains the pressure within the cabin around 8000 feet, allowing the pilot to breathe without the use of supplemental oxygen.

While these seals are not dynamic in the true sense of the word, they are constantly changing based on the altitude of the aircraft.

Most of the pressurization seals on our modern jets are static. But every door, including the luggage compartment, has seals that must be pressurized in order for the aircraft to maintain a safe level of oxygen in the cabin.

Do Jet Planes Blow Clean Air?

Many travelers worry about getting sick on airplanes. With tight quarters and no ability to open a window and get some air, travelers may wonder whether the air from the vents above them is blowing fresh air — or if it’s circulating stale air and germs.

A few months ago, I performed a non-scientific study on a flight by asking the passengers next to me what they thought of the circulated air in modern aircraft today. I was not surprised to find a wide range of answers, varying from someone envisioning a squirrel blower forcing air around the cabin, with others believing 100% of the air comes from the outside.

HEPA Filters on Airplanes

The truth lies somewhere in-between. Turns out, 50% of the air blowing through jet cabins is actually coming from the outside.

That’s one of the reasons why the air that blows through the vents is so cold — the 50% of air that comes from outside is around -30F, which is why stewardesses need to turn the heat on to keep us comfortable.

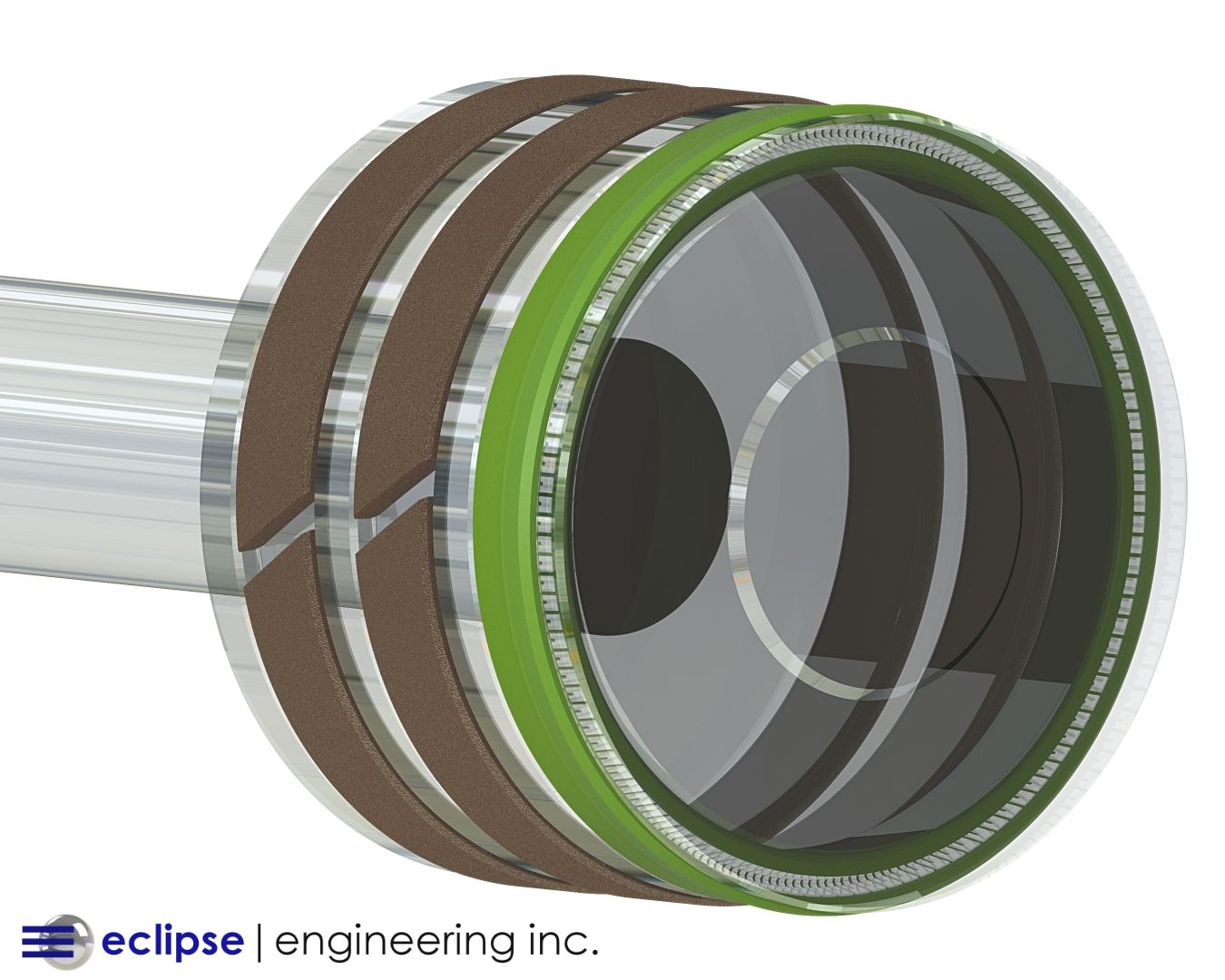

The rest of the air is recirculated air through a HEPA filter system, or “High Efficiency Particulate Air.”

This is the same air found in surgical operating theaters or clean rooms, with an efficiency that oftentimes exceeds 99% pure. In our modern-day aircraft, this filter helps stop the spread of whatever just came out of that guy’s mouth 5 rows up, cleans cigarette smoke, and even works to stop the spread of infectious viruses through the cabin.

If you’re traveling on one of the silver birds, your best option for the cleanest air is to turn that overhead jet on high and let it blow around your face. This funnel of air forces air that may be lingering around your nose and mouth aside, providing a fresh stream of clean cool air.

I spoke to the pilot or driver of an A320, who has seen the process of cleaning the HEPA Filters. He claimed it was about as nasty as cleaning…well…you get the point.

Another pilot friend of mine suggested that if you have to travel during the coronavirus outbreak, you should turn the air on and allow the HEPA filters the opportunity to blow clean, fresh air over your nasal cavities, promoting a safer ride and reducing the probability of infection.

So, bundle up, turn on the jets, and sit back and enjoy the ride. The door seals will keep you breathing, and the HEPA filters could keep you safe.