Silicone Filled Spring Energized Seals

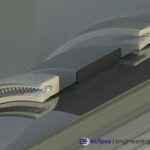

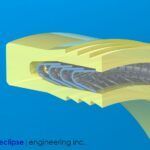

Filling a spring cavity with Silicone allows our customers to use a spring energized seal in environments where the media in the application does not come in contact with a metal spring.

There are many reasons to apply these this solution for various applications

1. Food Grade where we use an FDA Approved Silicone to cover the spring, and use a jacket material which is also FDA approved

2. When we are sealing a media that would hamper the ability of the spring to continue to be energized in the media. Media like an adhesive that will stop the spring from being active.

3. Filling a groove with Silicone where your goal is to have the least amount of fluid displacement for accurate positioning of a mechanical device.

There are several different types of Silicones depending on the usage. They can be for food grade use, high temperature, or by changing the viscosity they can act as a spring adding to the force of the existing spring.

PRODUCTS

INDUSTRIES

SUBSCRIBE TO OUR NEWSLETTER

Sign up for our newsletter and receive resources about seals, bearings, and shapes delivered directly to your inbox!